Microwave drying equipment and dynamic microwave emission drying method thereof

A microwave drying and equipment technology, applied in drying, drying machine, lighting and heating equipment and other directions, can solve the problem of uneven microwave field, large drying equipment, and scattered textiles that cannot achieve good drying effect and other problems, to achieve the effect of uniform microwave field, small size and uniform energy distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

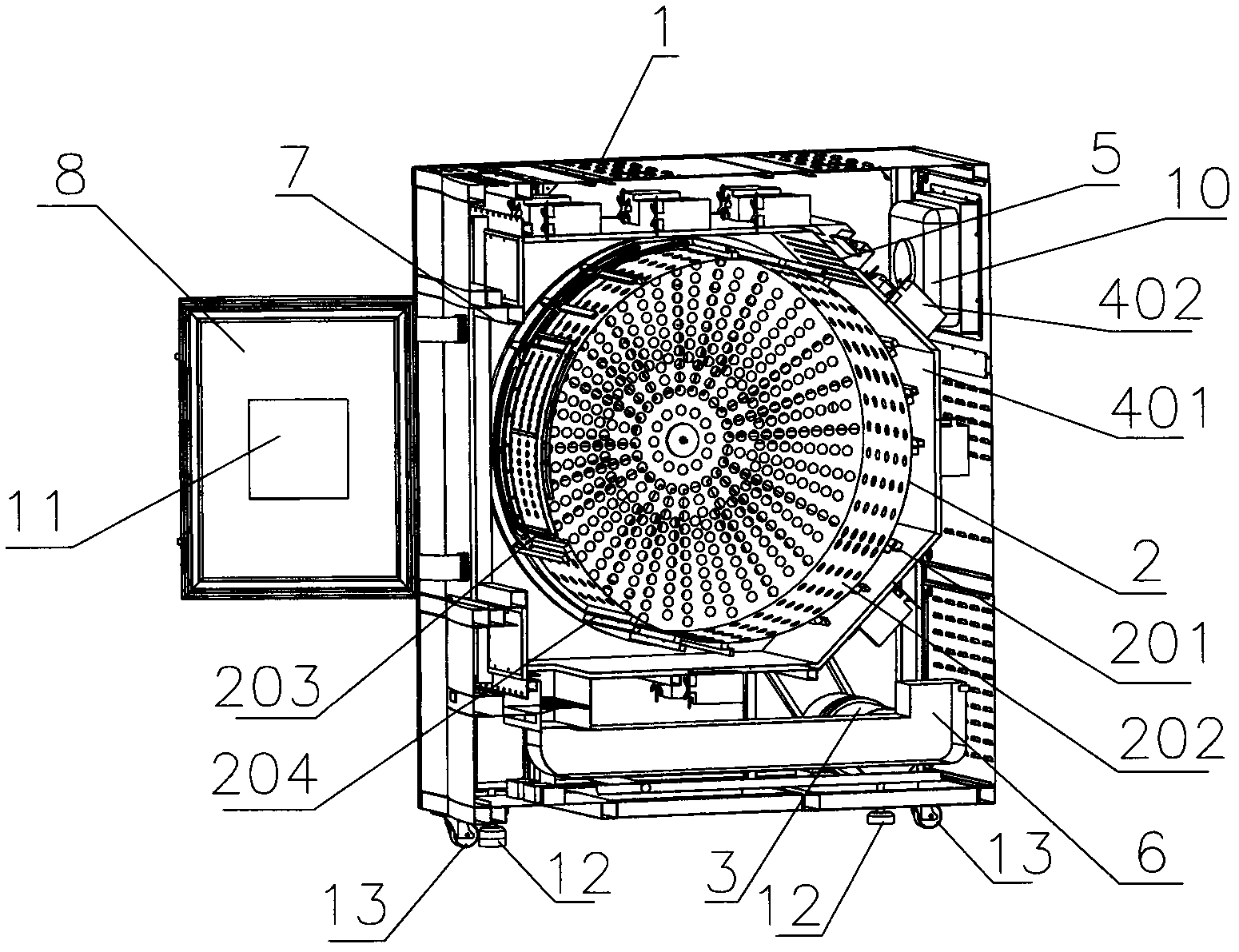

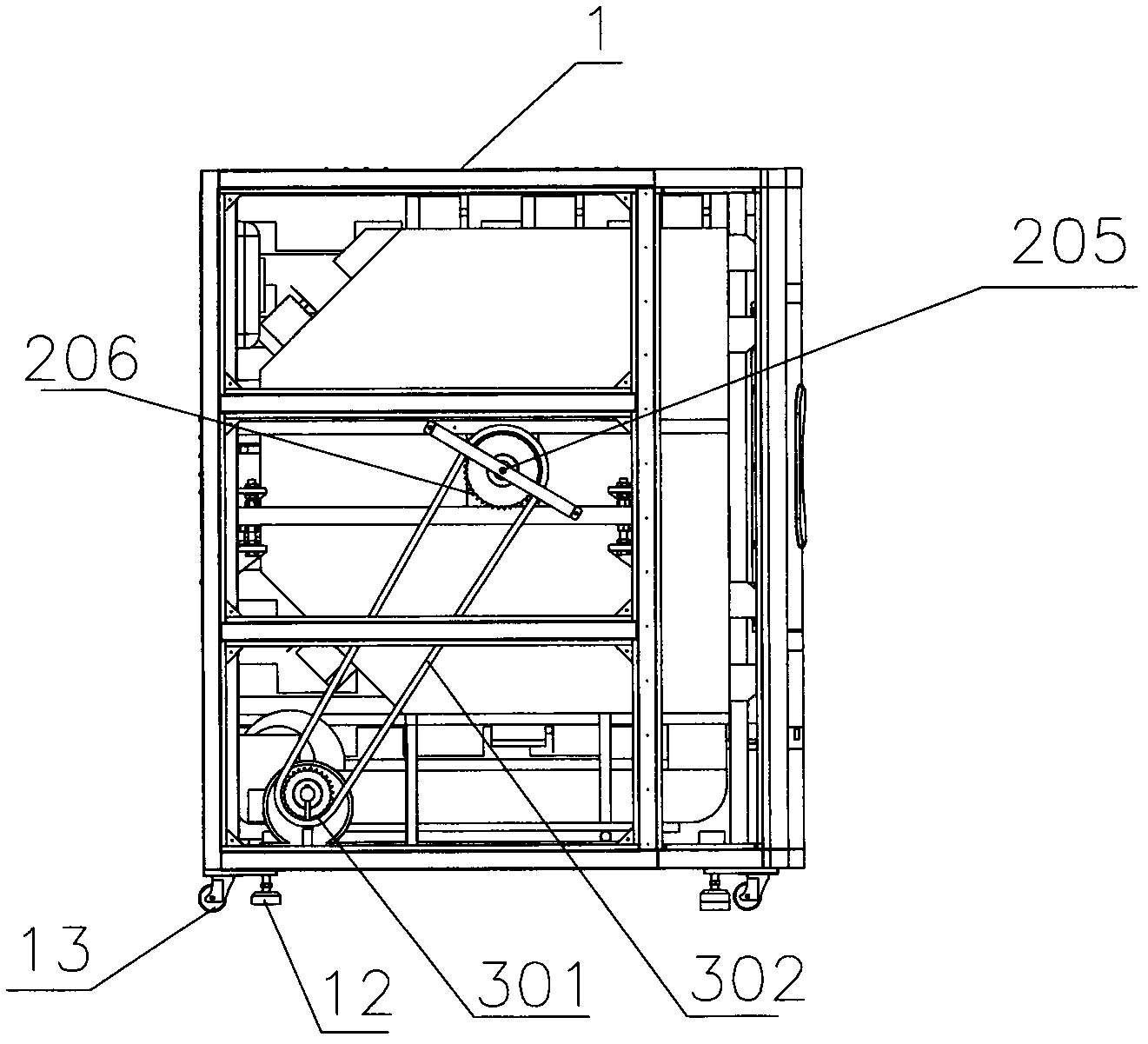

[0028] refer to figure 1 As shown, the microwave drying equipment disclosed in the invention includes a cabinet 1 , a drum 2 , a driving device 3 and a magnetron installation cavity 4 .

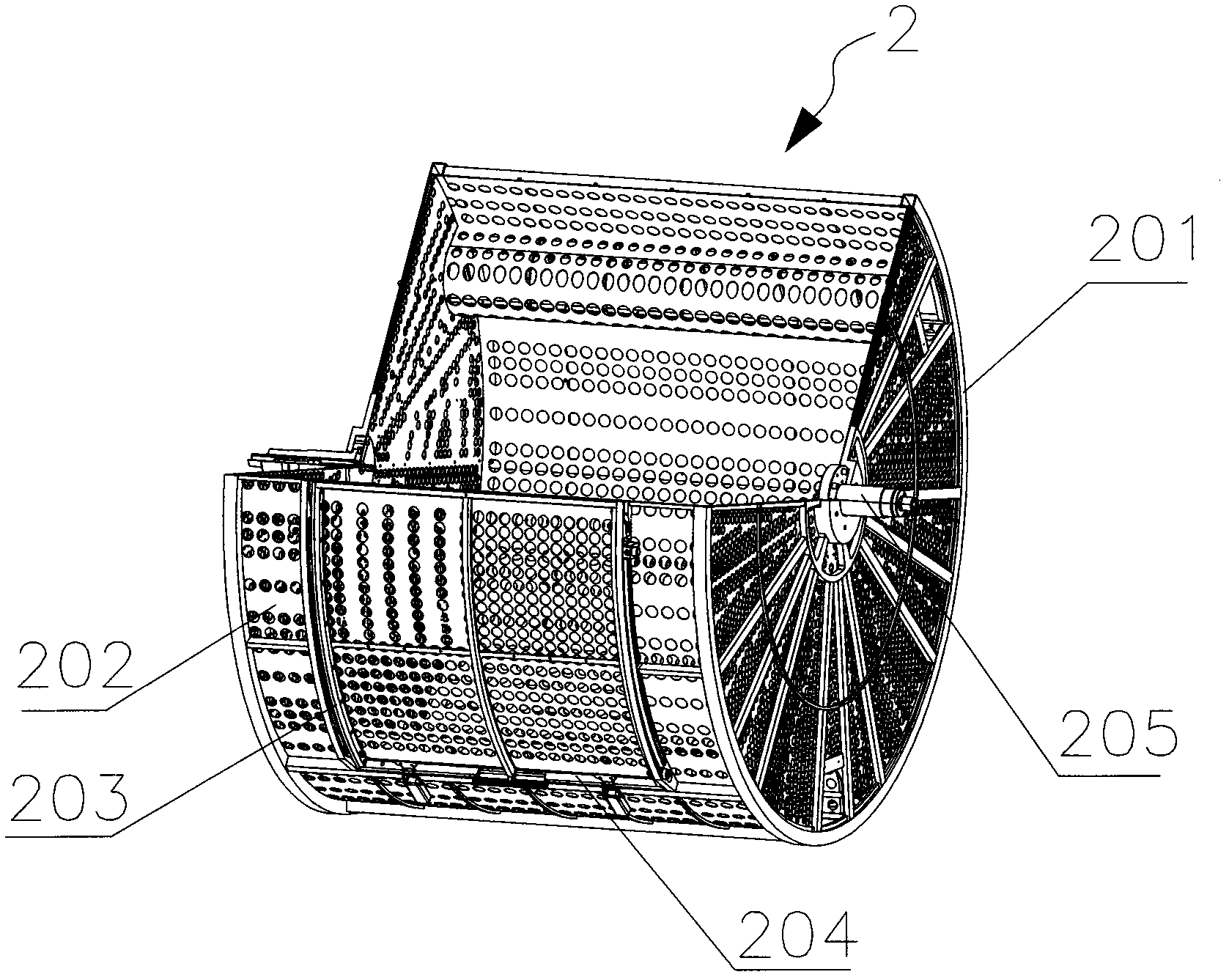

[0029] refer to image 3 As shown, the drum 2 includes a cylindrical drum frame 201 and a load net 202; the cylindrical surface of the drum frame 201 is provided with a feeding and retrieving opening 203, and the drum 2 is provided with a sliding door 204, and the feeding and retrieving Both sides of mouth 203 are respectively provided with a track, and the both sides of described sliding sliding door 204 are respectively provided with a pulley, and the pulleys on both sides of described sliding sliding door 204 are installed on the track of described feeding and taking material opening 203 both sides; The carrying net 202 is installed on the side and two bottom s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com