Straight-hole type spraying plate capable of preventing hollow cathode discharge

A hollow cathode discharge and spray plate technology, which is applied in the manufacture of circuits, electrical components, semiconductor/solid-state devices, etc., can solve problems such as arc discharge, achieve simple structure, improve process stability, and avoid glow discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

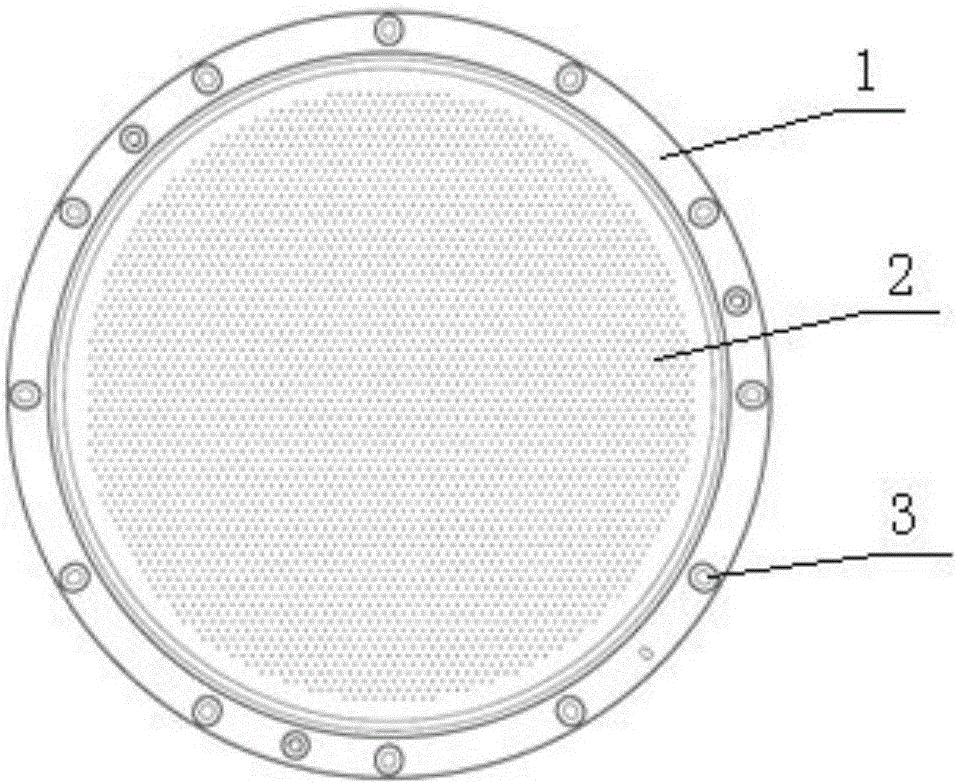

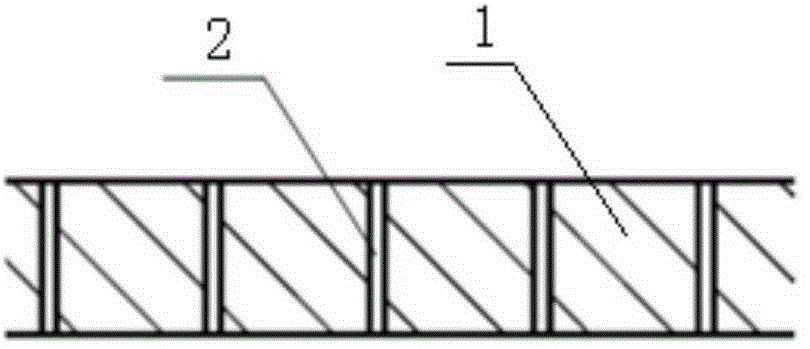

[0017] refer to Figure 1-Figure 3 , a straight-hole type spray plate for preventing hollow cathode discharge, comprising a spray plate main body 1 with a fixed screw hole 3, and a small hole 2 is formed on the spray plate main body 1.

[0018] The small hole 2 adopts an elongated structure;

[0019] The ratio of diameter to length of the small hole 2 is more than 1:6, and the maximum is 1:15;

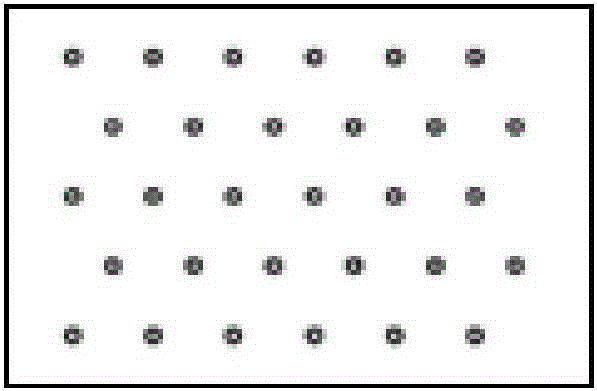

[0020] The small holes 2 are distributed in an equilateral triangle array, and the hole area is slightly larger than the area of the wafer.

[0021] In the present invention, since the small hole 2 adopts a slender straight hole structure, the flow resistance of the hole is very large, and there is a large pressure difference between the back and the front of the spray plate, so after the process gas is fully mixed from the top of the spray plate main body 1, It can spray out from the small hole 2 evenly. During the process, when the free electrons pass through the small hole 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com