Energy-saving and efficient fruit and vegetable dewatering and drying equipment and drying method

A technology for drying equipment and fruits and vegetables, which is applied in the preservation of fruits and vegetables, preservation of fruits/vegetables by dehydration, food preservation, etc., can solve the problem that it takes a long time to restore the pressure of the drying chamber, the amount of materials processed by air jets is small, and the mass production cannot be achieved. and other problems to achieve the effect of shortening drying time, avoiding glow discharge and improving drying uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

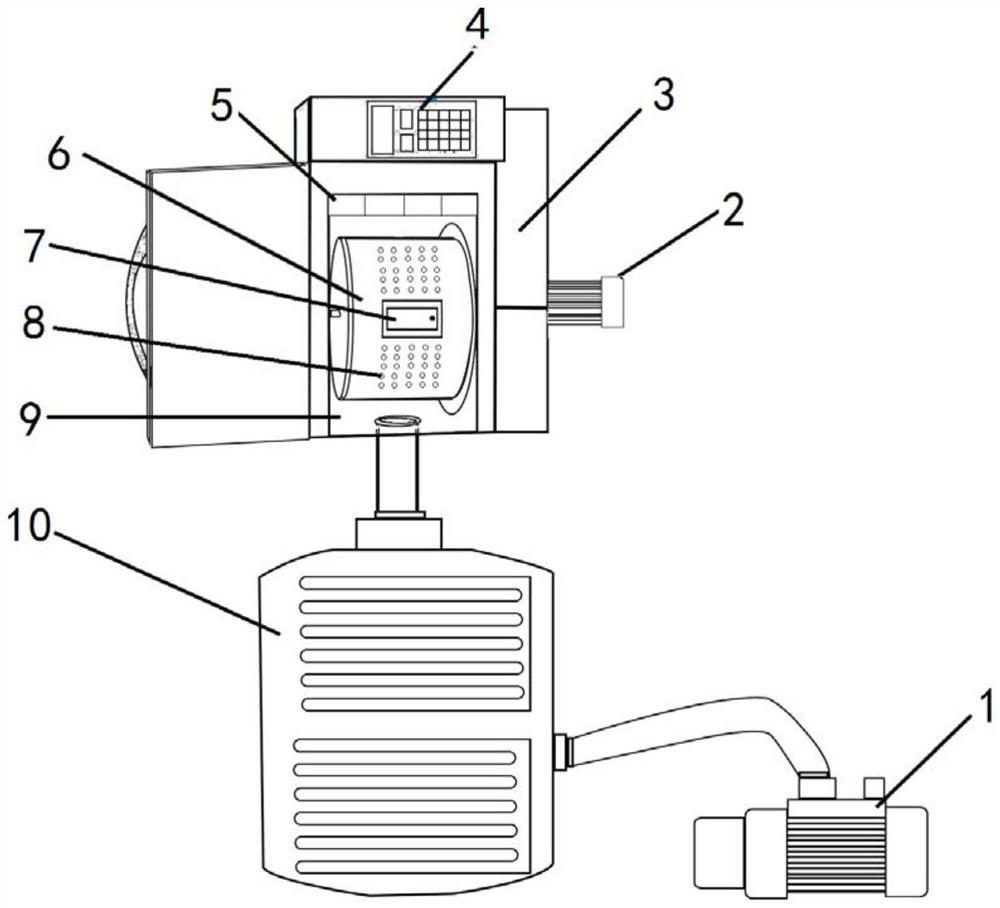

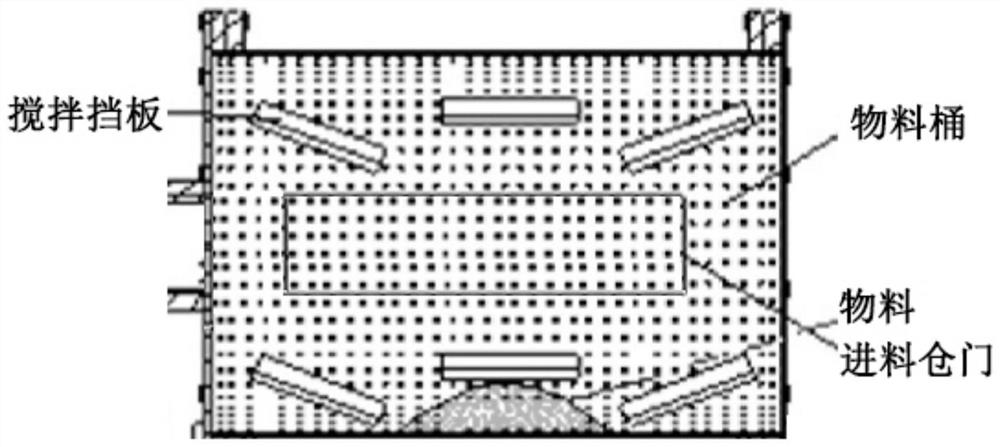

[0023] An energy-saving and high-efficiency fruit and vegetable dehydration and drying equipment. The material barrel 6 is placed in the microwave heating chamber 9. There are microholes 8 on the wall of the barrel for gas in and out, and a hatch 7 is provided on the side wall; the material barrel 6 is connected to an adjustable speed motor. 2. Optical fiber sensor; the microwave heating cavity 7 is placed in the box body 3, and there is a microwave generator 5 connected to the temperature control cold trap box 10; the temperature control cold trap box 10 is connected with a vacuum pump 1 and a freezing unit 13; The temperature and cold trap box 10, the microwave generator 5, the vacuum pump 1, and the motor 2 regulate the drying process through the control panel 4; the control panel is installed on the box body 3; there is a stirring baffle inside the material barrel.

[0024] The specific method of use of the drying equipment of the present invention is to open the hatch 7 of...

Embodiment 2

[0025] Example 2 Drying yam grains in the process of rotating synergistic multi-stage variable power microwave freeze-drying

[0026] Open the hatch 7 of material bucket 6, then load yam grain;

[0027] The rotation interval of the material barrel is 20 minutes, and the rotation time is 2 minutes

[0028] Pre-drying stage 0—0.5h: Open the temperature-controlled cold trap box, the microwave does not start, the heat conduction of the ambient temperature to the material promotes the biochemical part of the surface ice crystals, and the temperature of the material rises to -25°C.

[0029] Initial stage 0.5—2.0h: Keep the temperature-controlled cold trap box open, microwave power 600W, microwave loading power is low, moisture is gradually removed, and the temperature of the material rises slowly to -18°C;

[0030] The third stage 2.0-5.5h: Keep the temperature-controlled cold trap box open, the microwave power is 1200W, and the microwave loading power is the highest stage. At this...

Embodiment 3

[0033] Example 3 Drying Garlic in Cooperative Multi-Stage Variable Power Microwave Freeze-drying Process of Rotation

[0034] Open the hatch 7 of material bucket 6, then load garlic;

[0035] The rotation interval of the material barrel is 30 minutes, and the rotation time is 3 minutes

[0036] Pre-drying stage 0-0.5h: Open the temperature-controlled cold trap box, the microwave does not start, the heat conduction of the ambient temperature to the material promotes the biochemical part of the surface ice crystals, and the temperature of the material rises to -20°C.

[0037] Initial stage 0.5—1.5h: Keep the temperature-controlled cold trap box open, the microwave power is 650W, the microwave loading power is low, the moisture is gradually removed, and the temperature of the material rises slowly to -15°C

[0038] The third stage 1.5-4.5h: Keep the temperature-controlled cold trap box open, the microwave power is 1300W, and the microwave loading power is the highest stage. At t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com