Patents

Literature

31results about How to "Guaranteed drying rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

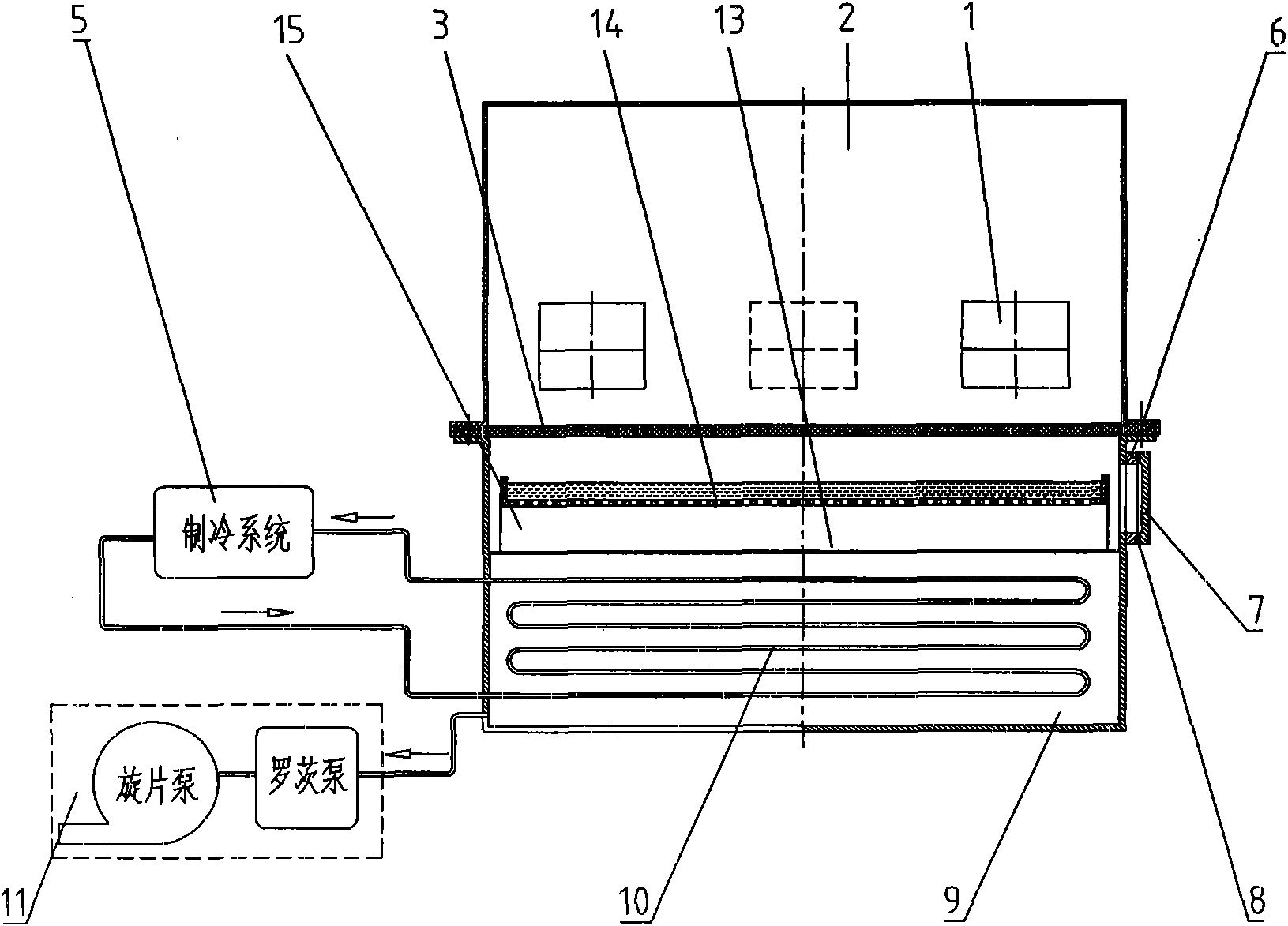

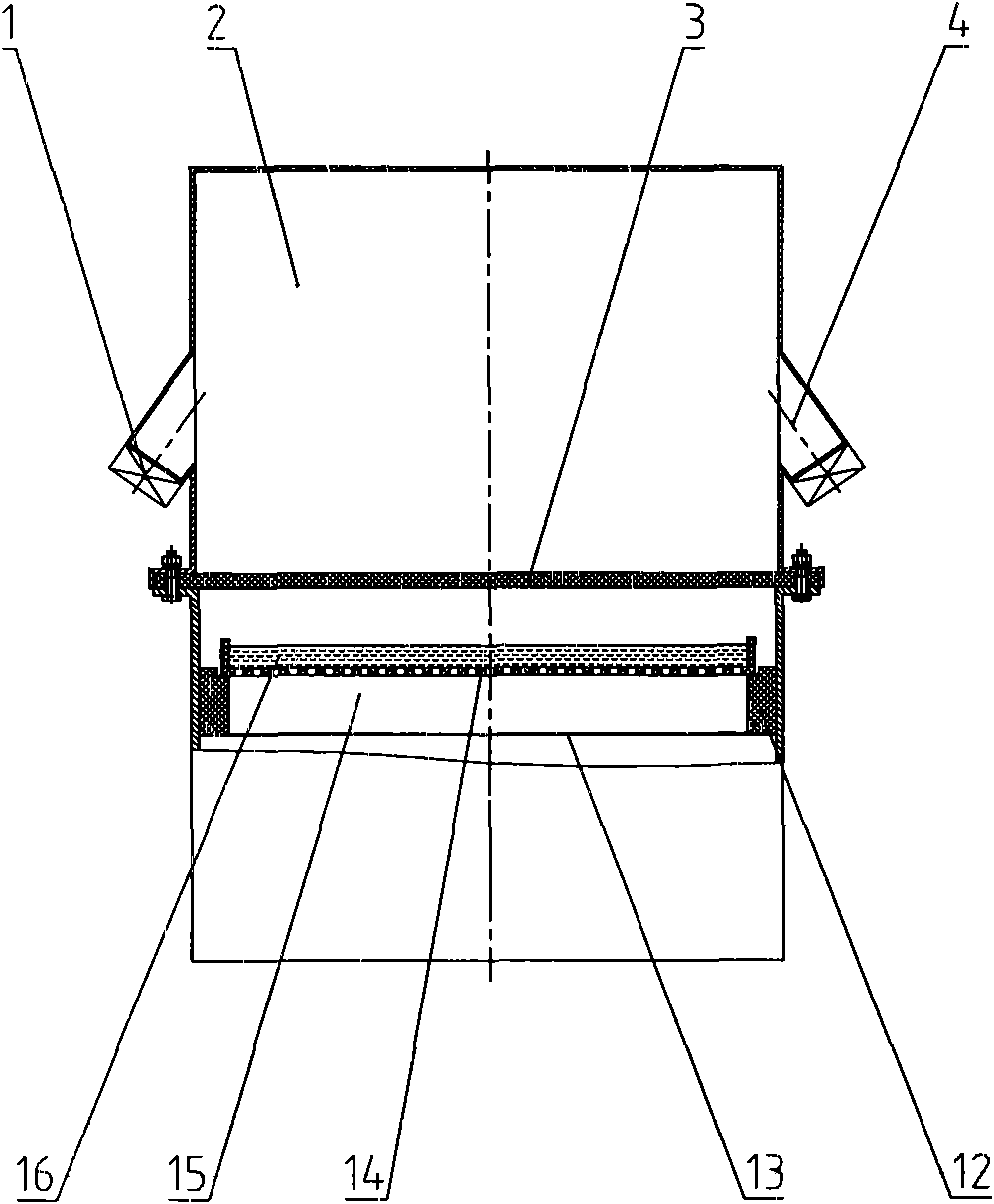

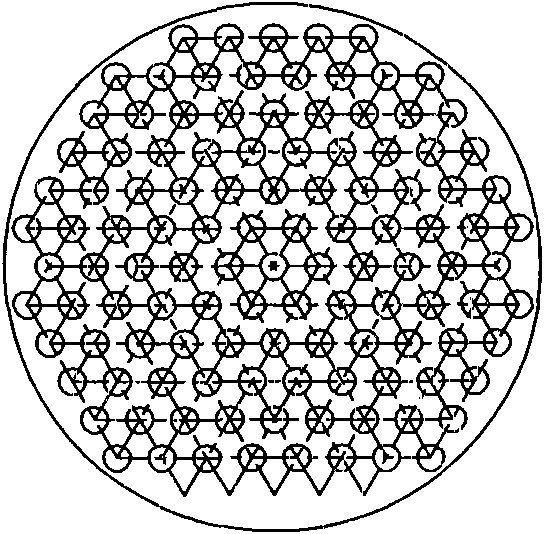

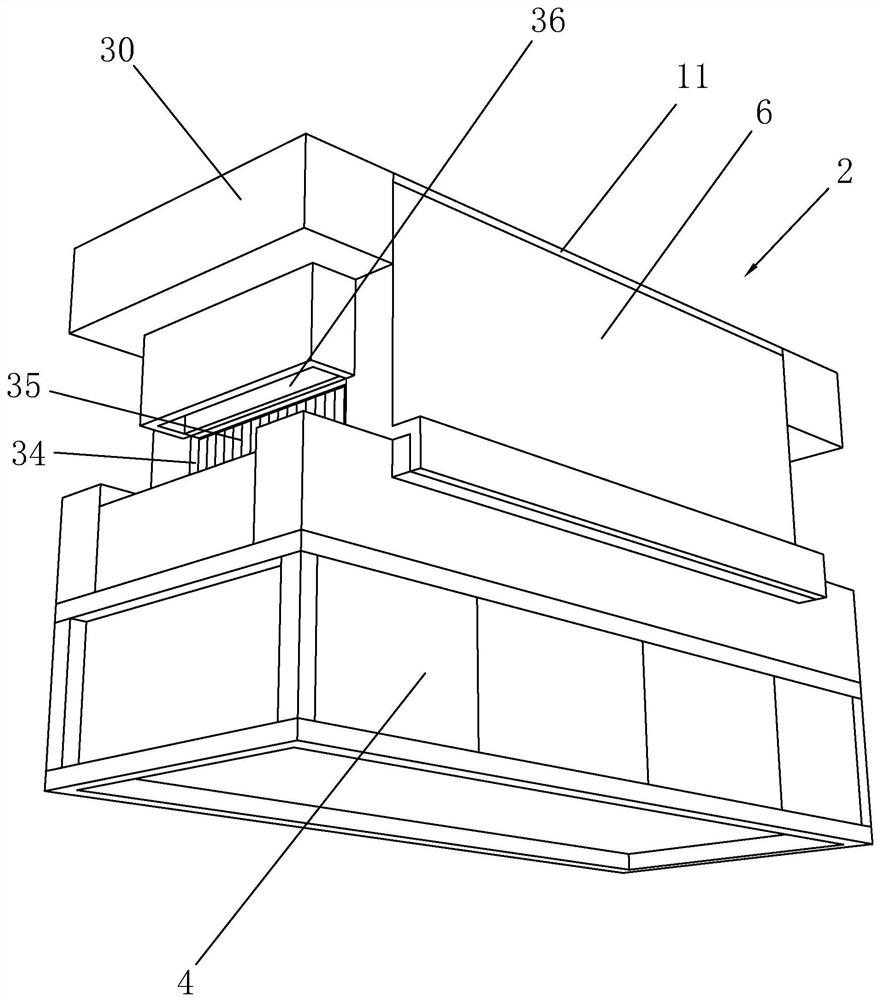

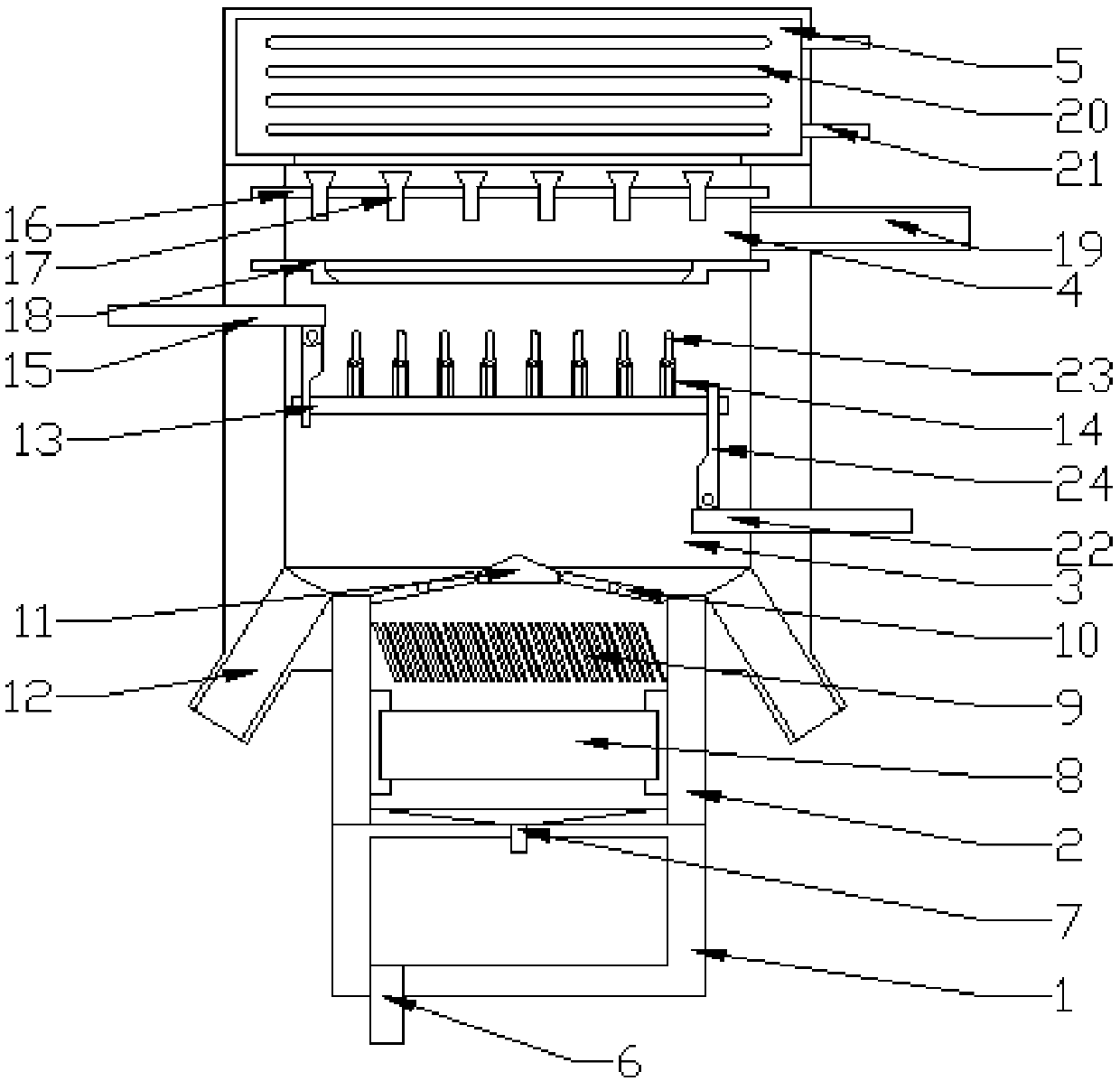

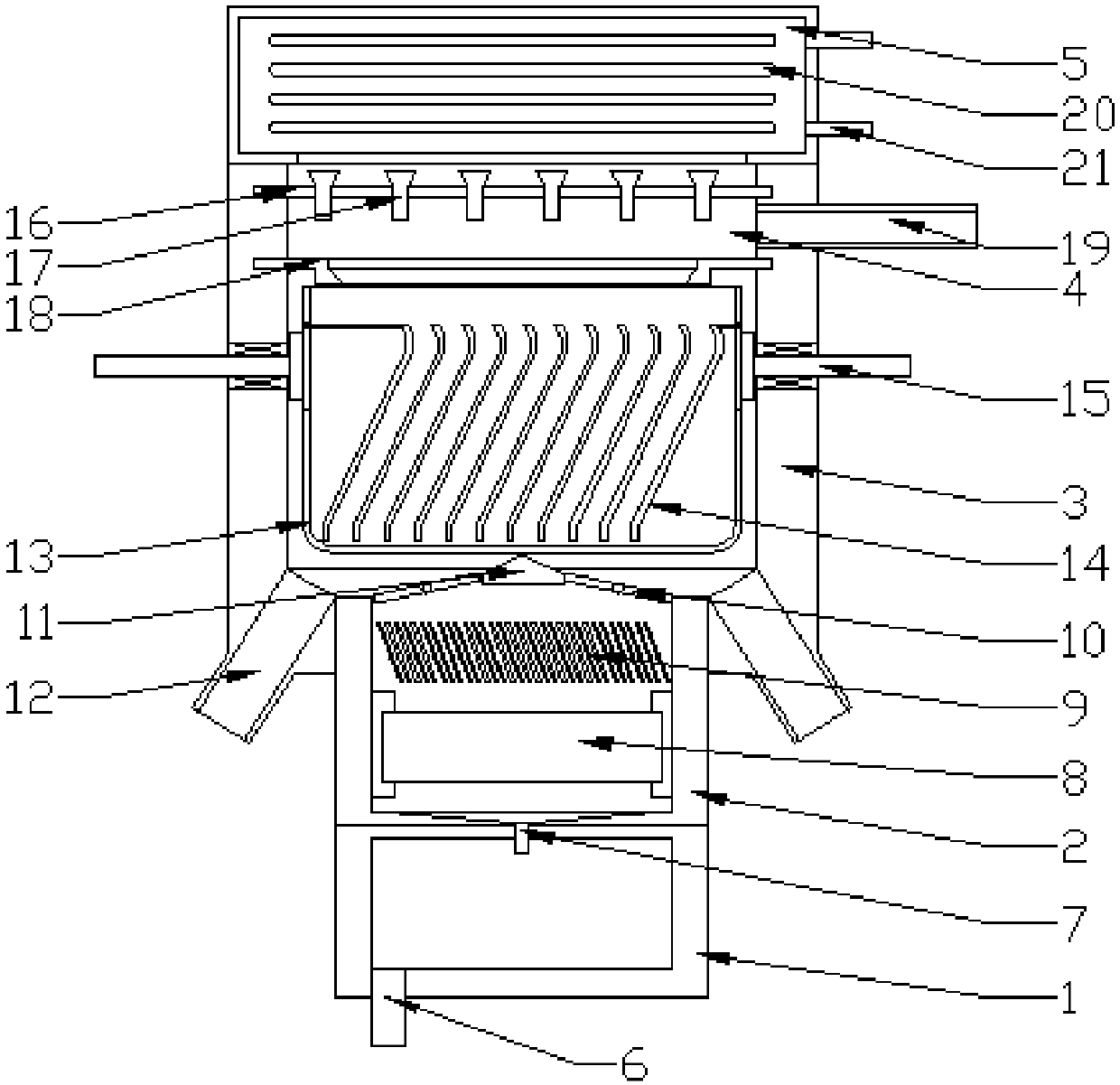

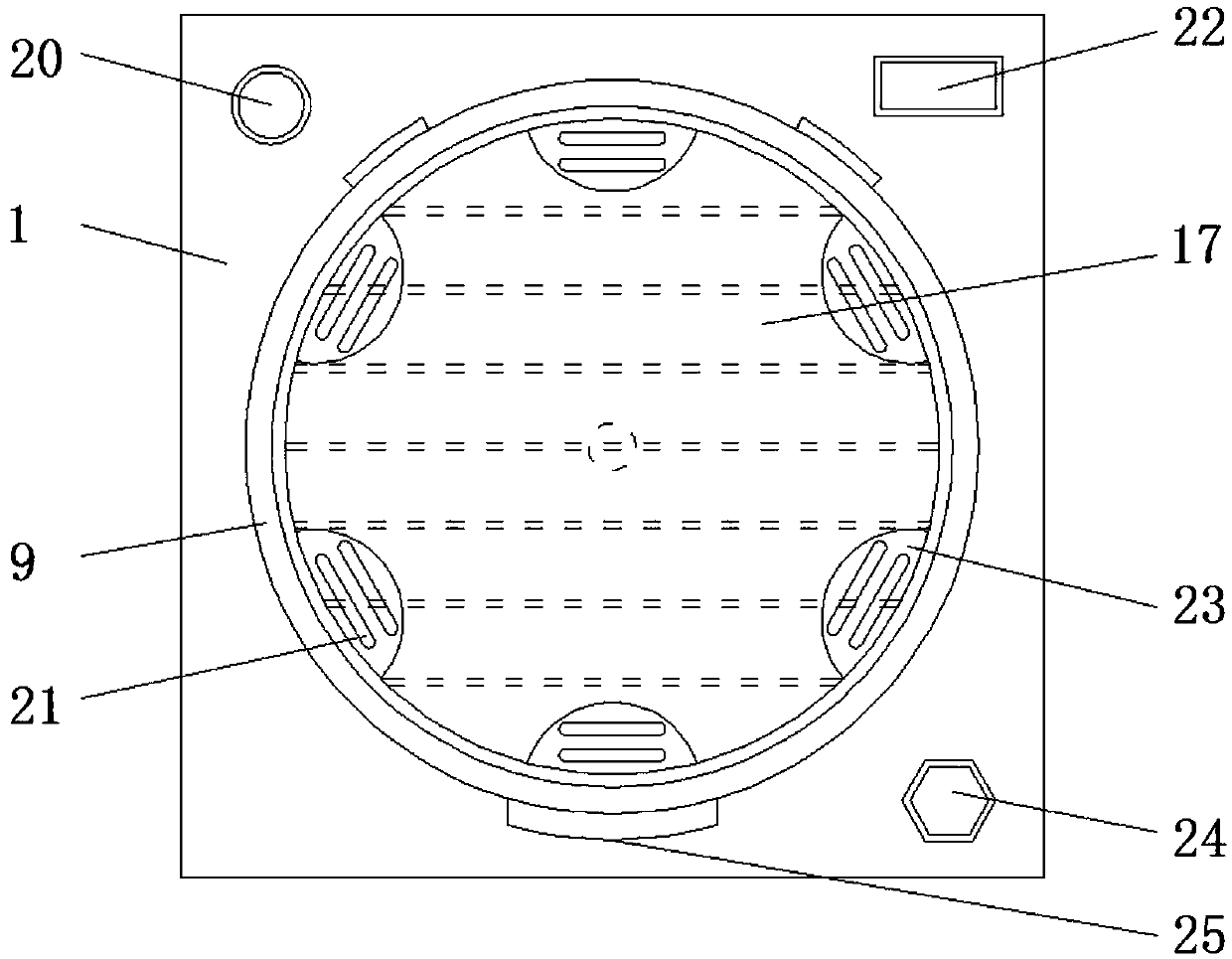

Double-chamber differential pressure type microwave vacuum freeze drying equipment

InactiveCN101608862ADischarge phenomenon will not occurAvoid discharge phenomenonDrying using combination processesFreeze dryEngineering

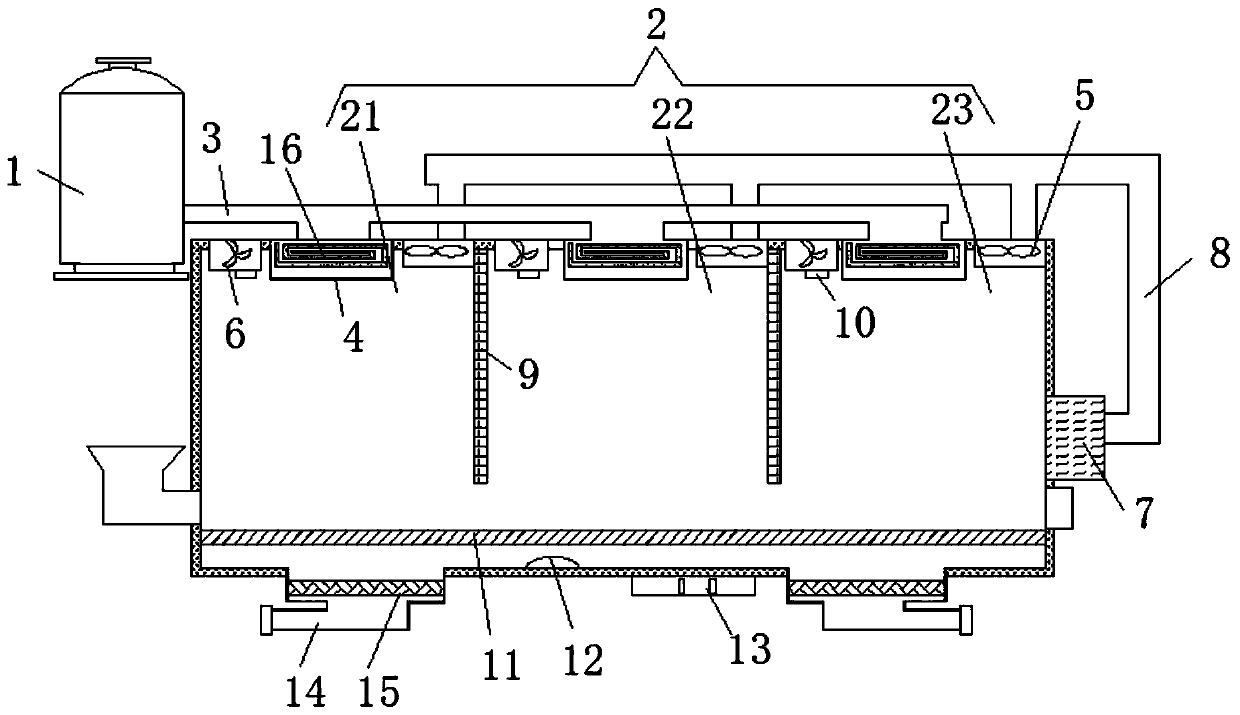

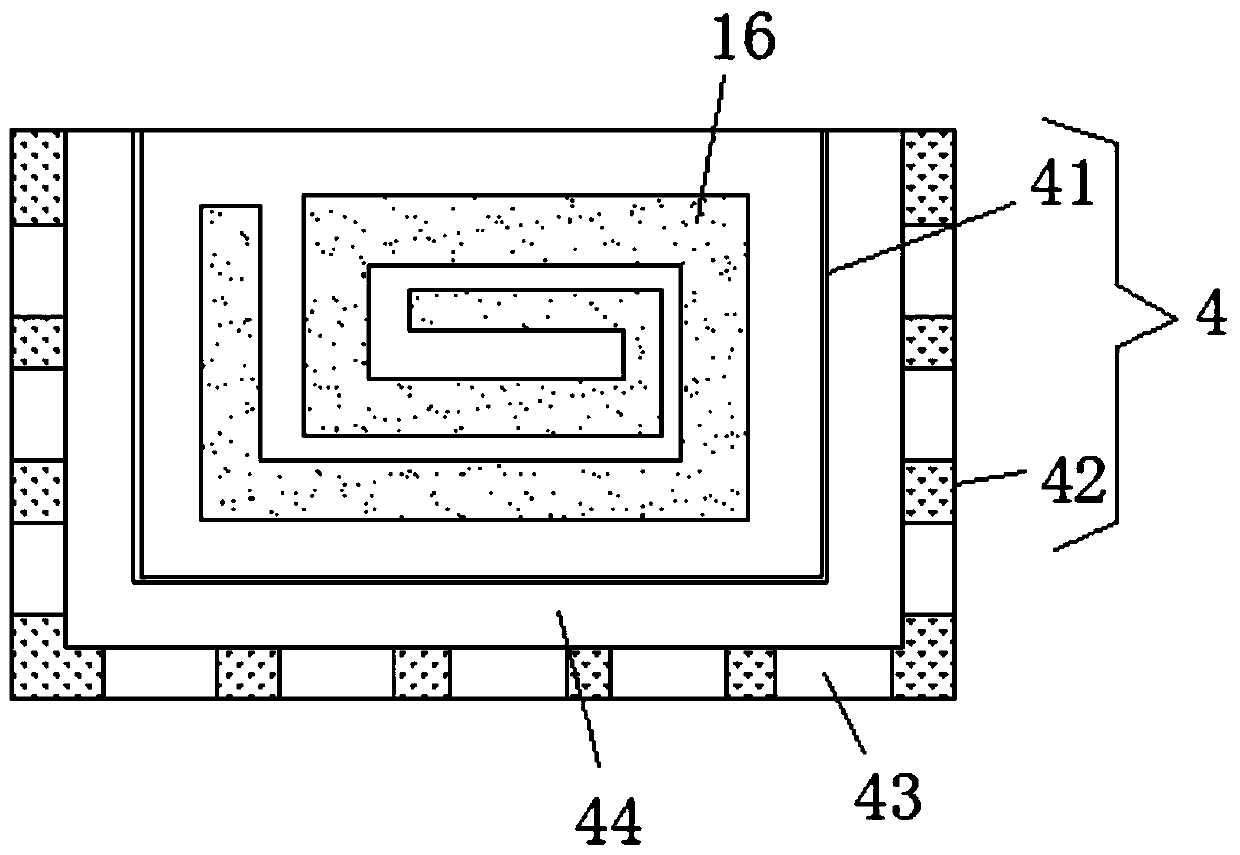

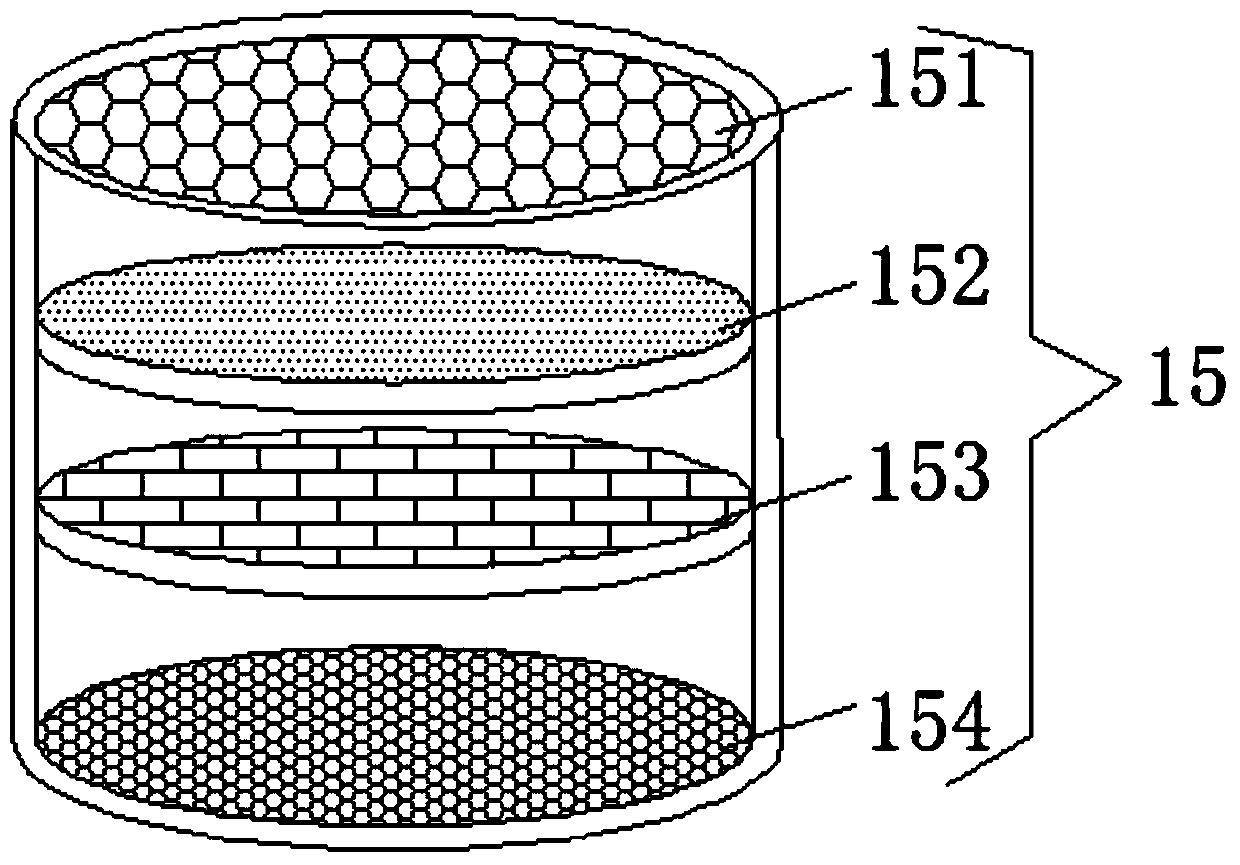

The invention relates to double-chamber differential pressure type microwave vacuum freeze drying equipment and belongs to the technical field of food and drug machines; the equipment essentially consists of a chamber body which is provided with a microwave magnetron, and a cold trap which captures the water vapor; a material bearing device is arranged in the chamber body which is divided into a first chamber and a second chamber by a transmission flow-separating plate; the magnetron is positioned in the first chamber, the relative vacuum degree of which is less than the discharge critical value; and the material bearing device is located in the second chamber which is linked with the cold trap through a shielding overflowing sheet. By adopting the microwave vacuum freeze drying equipment, not only can adequate microwave generation power and ideal vacuum degree be maintained, thereby ensuring the required drying rate, but also the generation of discharge phenomena can be avoided as the discharge boundary conditions are inhibited respectively in the first chamber and the second chamber.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

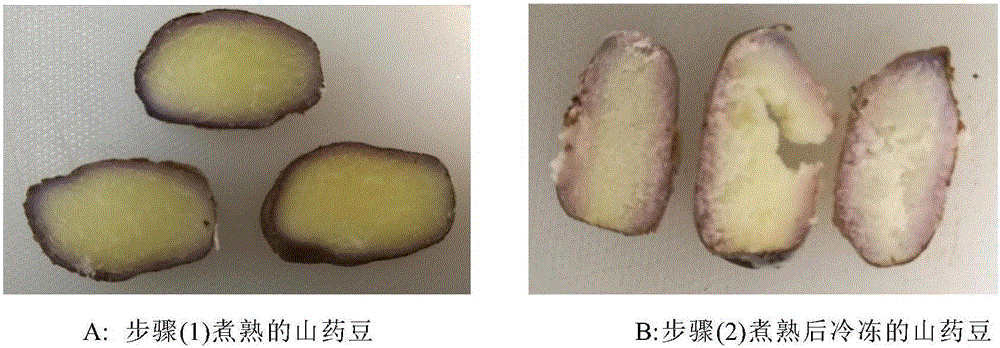

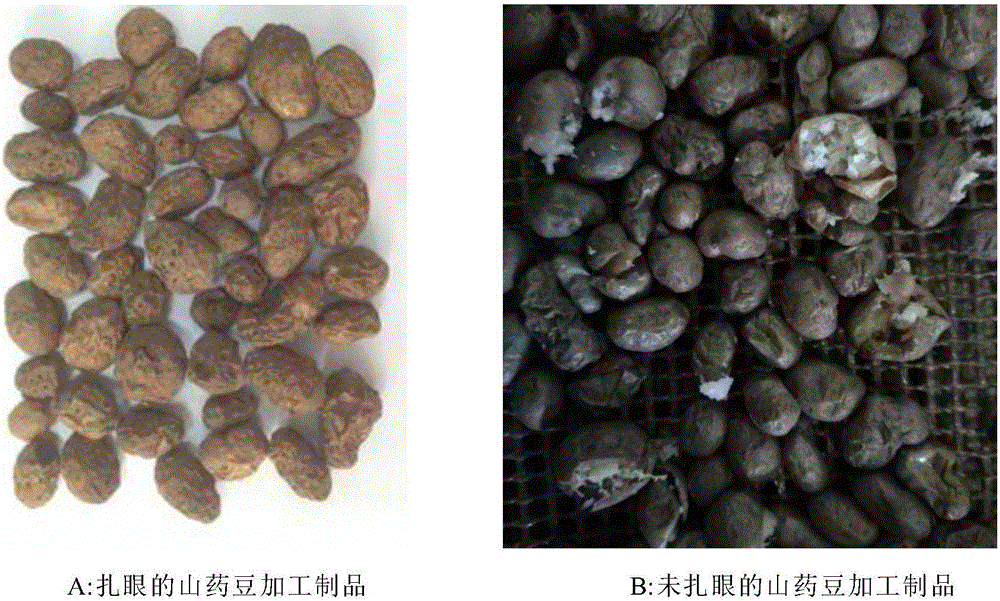

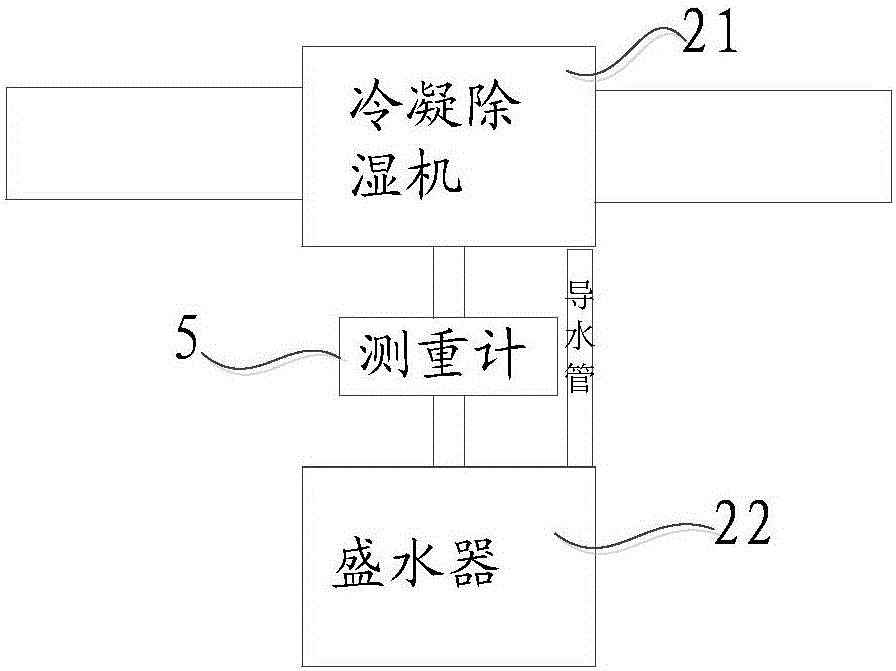

Preparation method of leisure dioscorea batatas bean and leisure dioscorea batatas bean prepared by adopting same

InactiveCN106690170ALoose structureCrispy tasteFood ingredient functionsFruits/vegetable preservation by freezing/coolingChemistryAdditive ingredient

The invention provides a preparation method of leisure dioscorea batatas bean and the leisure dioscorea batatas bean prepared by adopting the preparation method. The preparation method is characterized in that processing and preparation are carried out after cooking and freezing and also comprises the steps of pricking holes, seasoning and packaging. The preparation method provided by the invention has the advantages that internal tissues of the dioscorea batatas bean can be softened, moisture inside the tissues can be more beneficially gathered and form ice crystals, particles are enlarged, and holes left by the ice crystals inside the dioscorea batatas bean after reprocessing enable the dioscorea batatas bean to be loose in structure and taste; and meanwhile, a hole pricking method is adopted, so that seasoners can enter the cooked dioscorea batatas bean more easily, burst of the dioscorea batatas bean in a reprocessing process is also reduced, and complete shape of the dioscorea batatas bean is fully maintained. The prepared dioscorea batatas bean remains functional ingredients and taste of the dioscorea batatas bean, is prolonged in quality guarantee period, can be stored and transported at normal temperature and is a convenient and leisure dioscorea batatas bean functional dietary therapy product.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

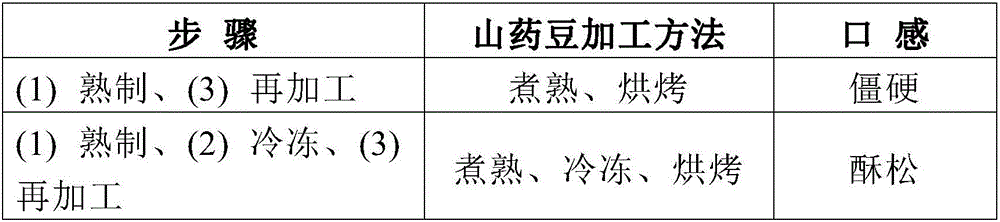

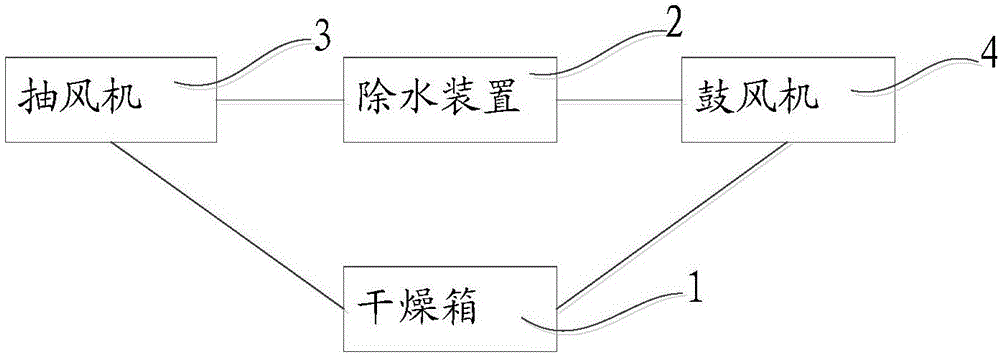

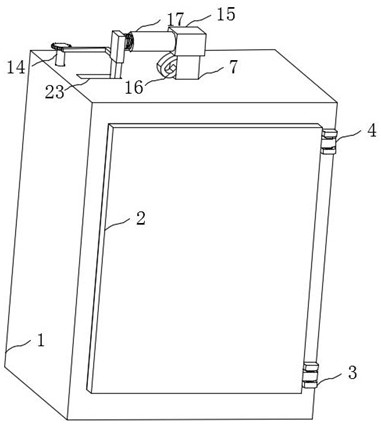

Drying equipment

InactiveCN106382805ASolve the problem of difficult measurement of moisture emissionAvoid getting lostDrying gas arrangementsDrying chambers/containersPulp and paper industryCoal

The invention discloses drying equipment. The drying equipment comprises a drying box arranged in a sealed manner, a hot air guiding device for guiding hot air into the drying body as well as a water removal device for absorbing water molecules in air flowing out of an air outlet of the drying box; an air outlet of the hot air guiding device communicates with an air inlet of the drying box; and an air inlet of the hot air guiding device communicates with the air outlet of the drying box. In the drying equipment, sealed drying is performed firstly, and materials in the drying box can be effectively prevented from being polluted. Water is removed through circulating ventilation of the hot air guiding device and the water removal device, the drying speed can be guaranteed, the content of the water in the materials can be obtained directly according to the weight of the water absorbed by the water removal device, a heat conduction system is sealed, and the materials are prevented from being lost in the air, so that the drying equipment can effectively solve the problem that the water diffusion amount after a coal sample is dried is difficult to measure.

Owner:长沙开元仪器有限公司

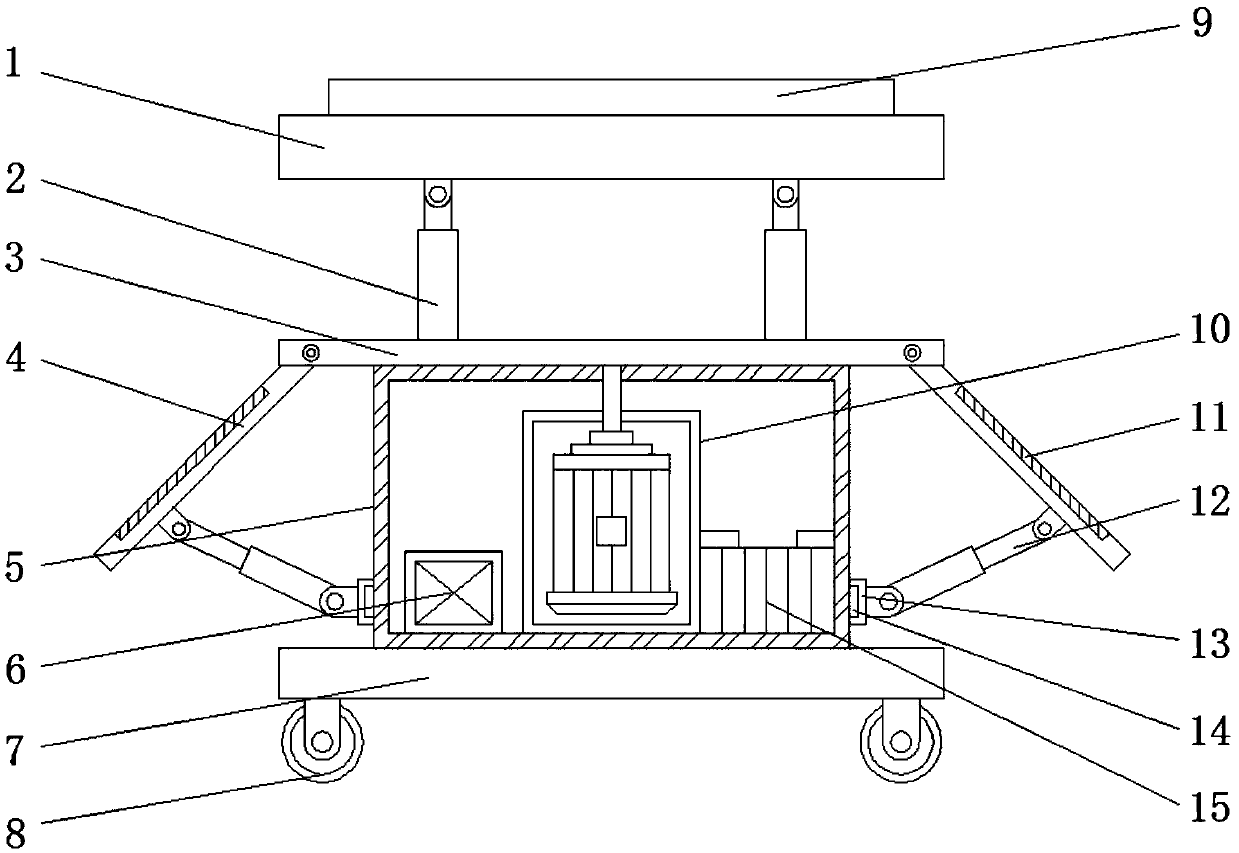

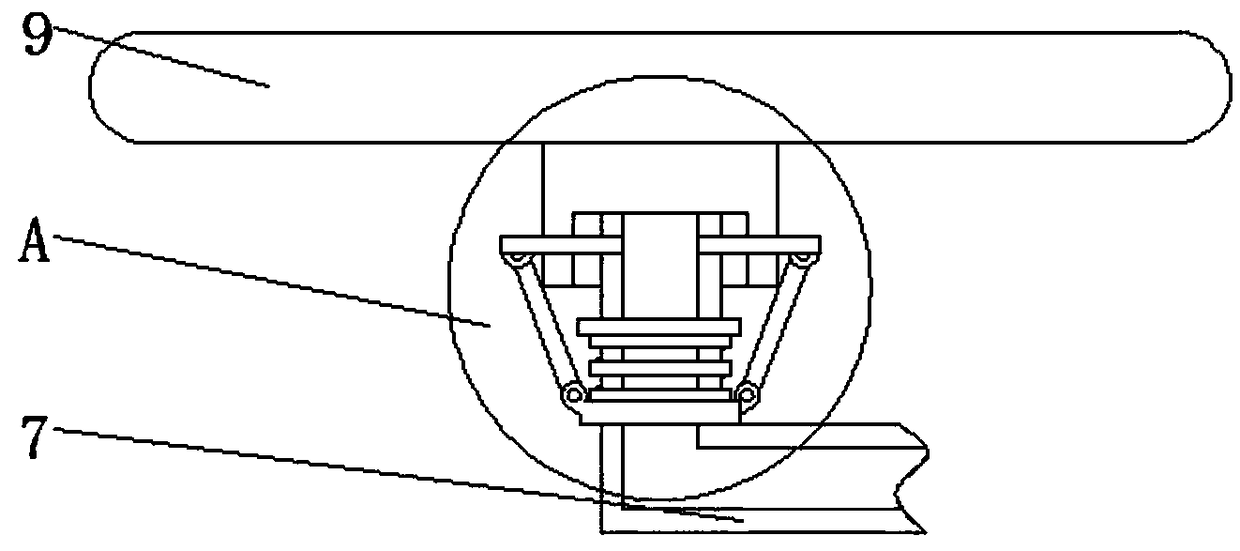

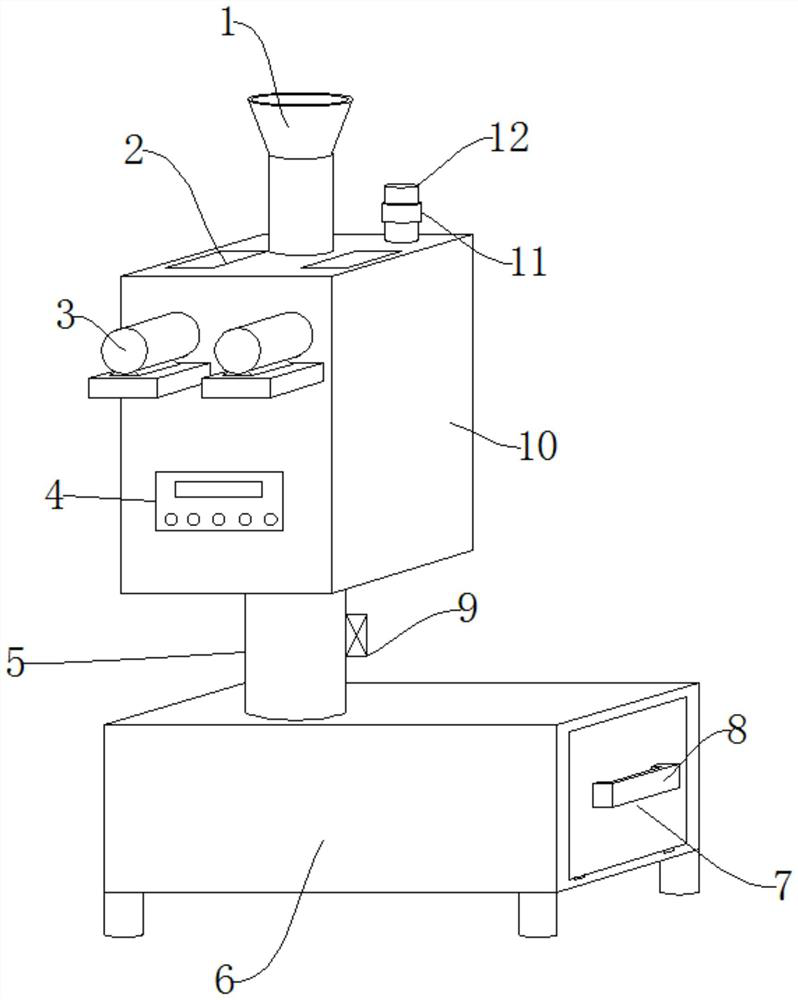

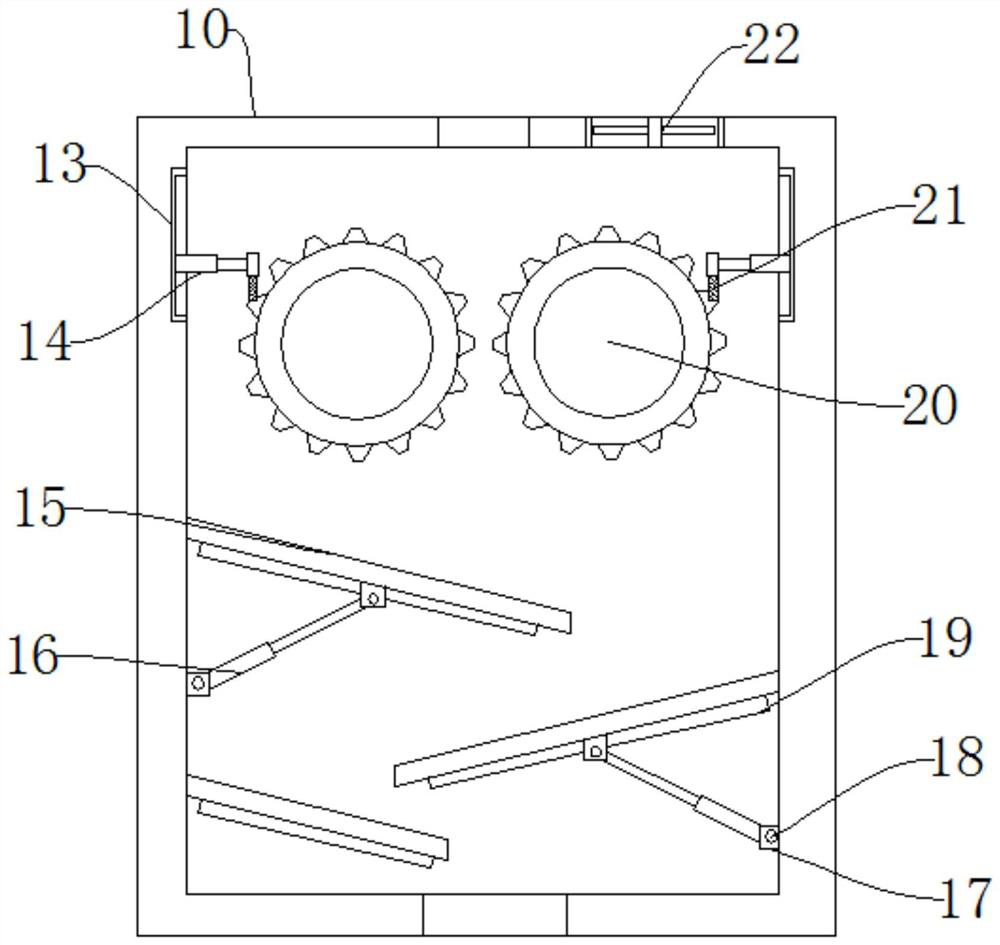

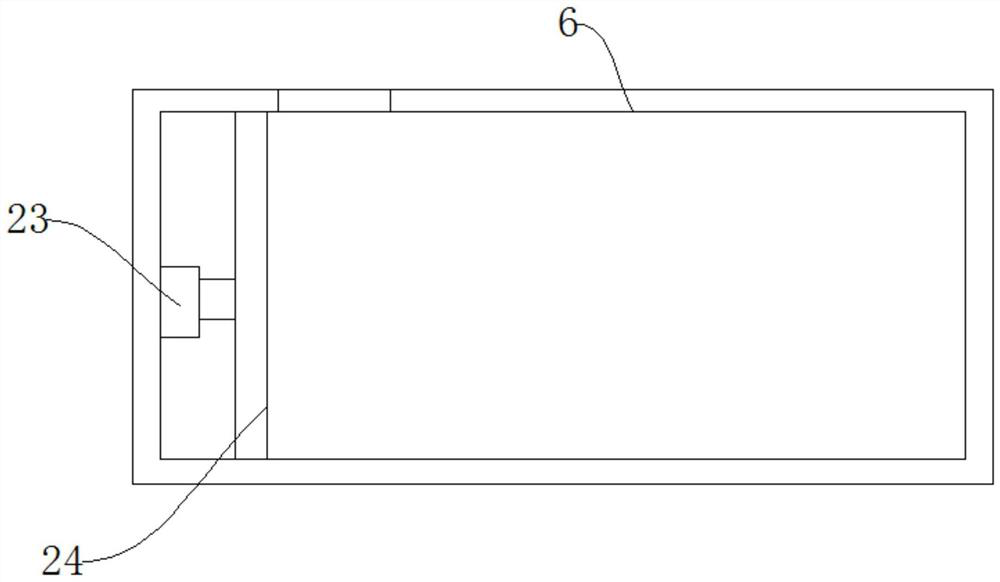

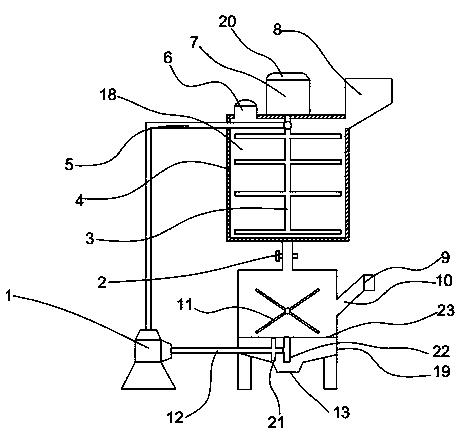

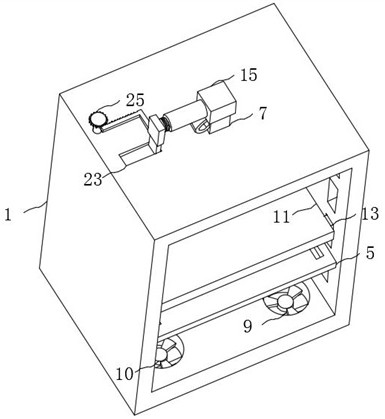

Drying device for biological organic fertilizer manufacturing

InactiveCN108917371AImprove drying efficiencyGuaranteed drying rateSievingManure dryingHeat conductingAgricultural engineering

The invention discloses a drying device for biological organic fertilizer manufacturing. By the drying device, fertilizer drying efficiency can be improved greatly, and fertilizer drying degree can becontrolled through rotating speed of a rotating barrel. Airflow in a drying barrel is high in air exchange efficiency, and hot air inside the drying barrel is dissipated out by the rotating barrel; when the rotating barrel rotates, sufficient mixing of blown-in hot air and fertilizer can be ensured, and drying efficiency is improved; a heating component is arranged outside the drying barrel and processes the drying barrel by adopting heat conducting fins, the drying barrel is uniform in temperature and high in drying efficiency, and a mode of simultaneous inside-outside drying is adopted, sothat drying rate and drying uniformity of the fertilizer are ensured greatly. In addition, the drying device can be matched with a fertilizer screening component in use, so that fertilizer manufacturing efficiency is improved greatly, and labor intensity is lowere.

Owner:ANHUI SCI & TECH UNIV

Method for measuring content of quantum dot surface ligand and quantum dot ink preparing method

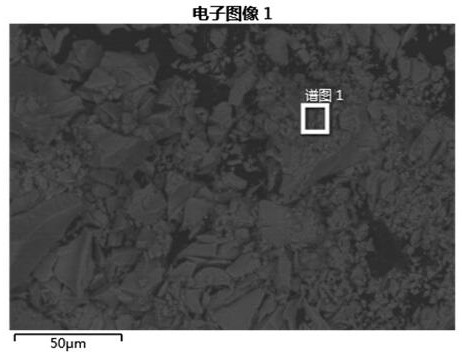

ActiveCN109932405ASimple methodWide range of applicationsChemical analysis using titrationMaterial electrochemical variablesPhysicsImage resolution

The invention provides a method for measuring the content of quantum dot surface ligand and a quantum dot ink preparing method. When the method is used for preparing quantum dot ink, the uniformity ofquantum dot ink quality can be ensured, the consistency of the solubility, drying rates and coffee ring effects of different batches of quantum dot ink is guaranteed, and the pixel resolution and uniformity of the lighting voltages and photoelectric efficiency of the quantum dot display panel are improved.

Owner:TCL CORPORATION

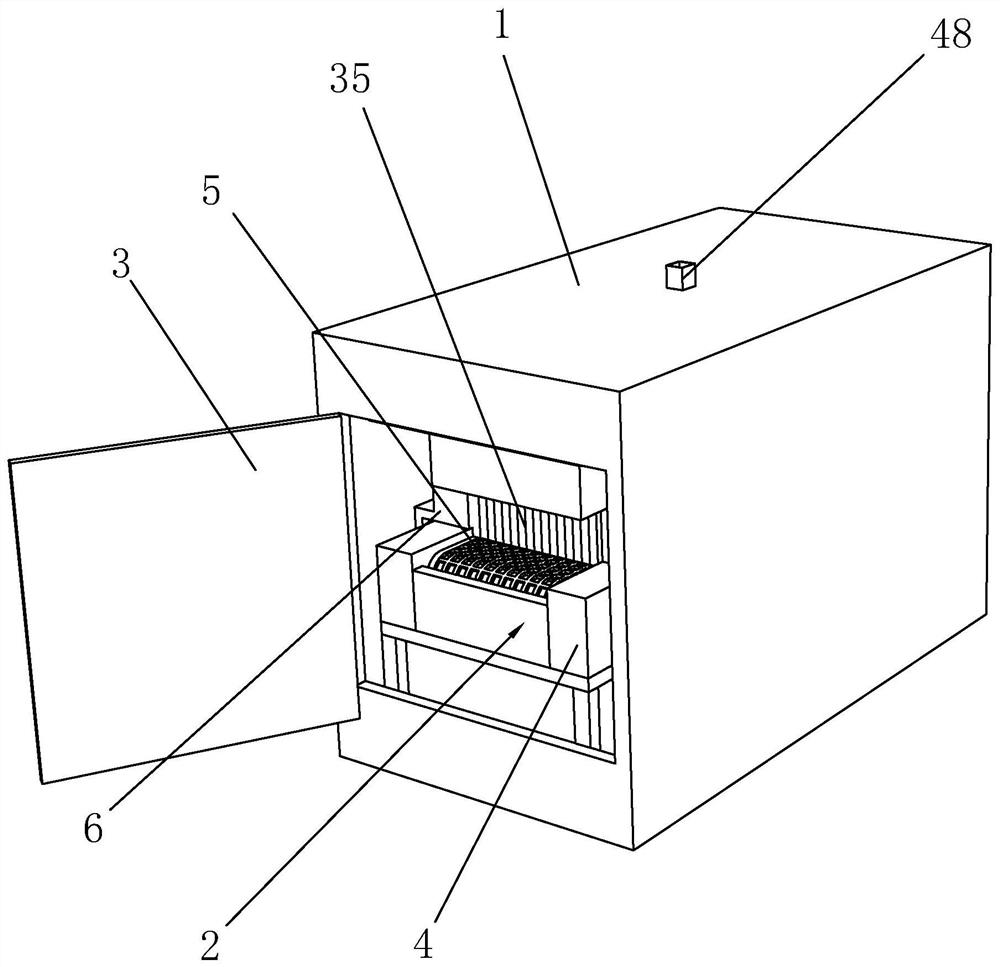

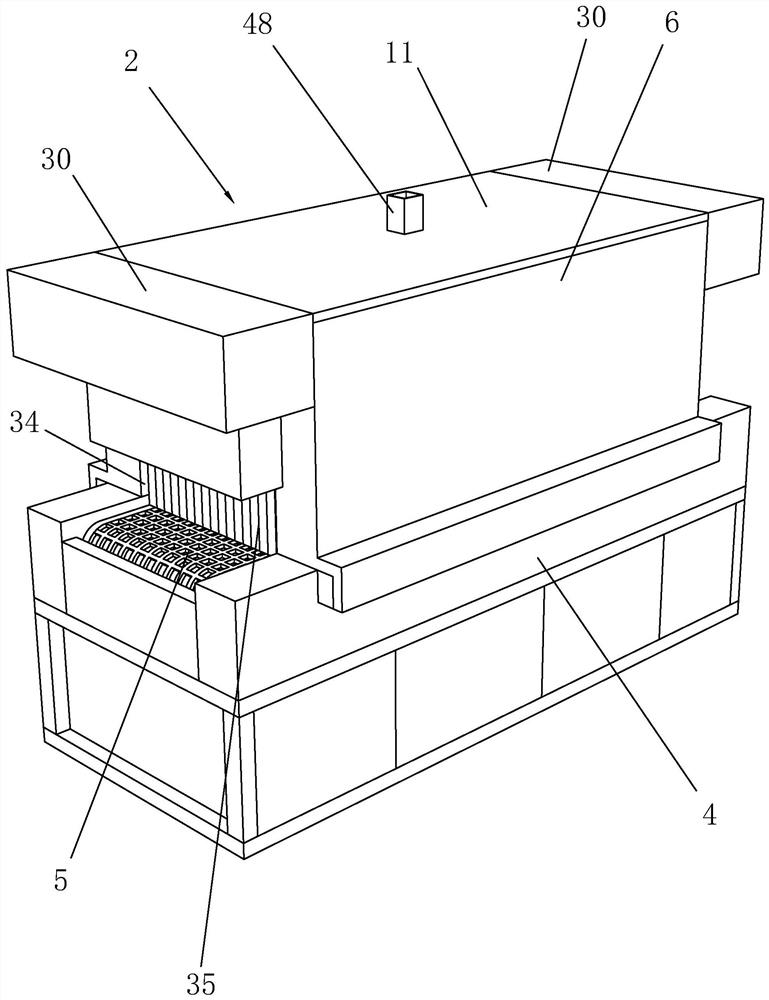

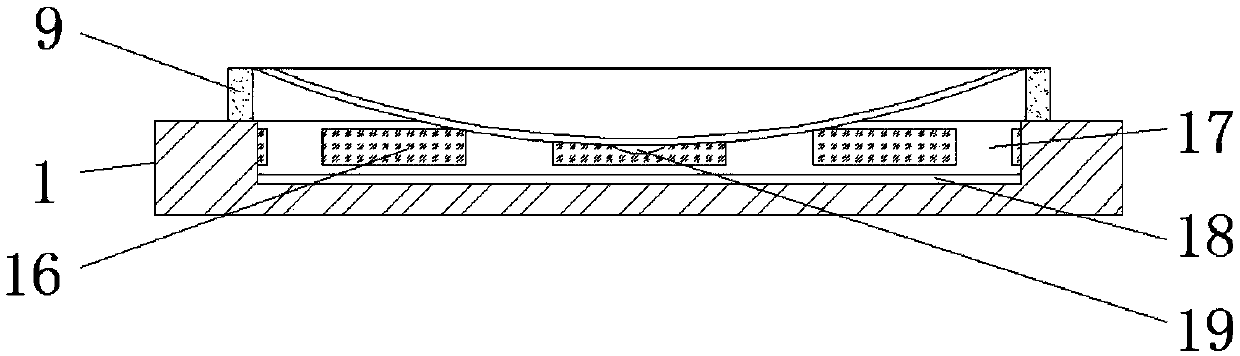

Vacuum drying device of stepping type ultrasonic cleaning machine and method thereof

ActiveCN111750617AReduce lossesIngenious and reasonable designDrying solid materials without heatDrying gas arrangementsAir volumeMegasonic cleaning

The invention discloses a vacuum drying device of a stepping type ultrasonic cleaning machine. The vacuum drying device comprises a sealing shell and a drying mechanism. The drying mechanism is located in the sealed shell. The drying mechanism comprises a support, a mesh belt conveying assembly, an inner shell cover and a drying assembly. An air guide cover is arranged in the inner shell cover. Anopening adjusting assembly is arranged at a bottom air port of the air guide cover, and the drying assembly is located in the inner shell cover and comprises a main drying frame and an auxiliary drying frame. A manufacturing method of the device comprises the following steps that 1) the angle of an auxiliary drying plate is adjusted; 2) the size of the air port is adjusted; 3) a product is dried;and 4) the product is detected. The size of the air port is adjusted through the opening adjusting assembly, so that the air volume and air pressure of hot air are changed, and the drying quality ofthe product is ensured. The main drying frame and the auxiliary drying frame are simultaneously used for hot air spraying and drying, so that the drying rate can be improved; and the angle of the auxiliary drying frame is adjustable, so that the spraying angle of the hot air can be adjusted, and the drying quality is improved.

Owner:XINCHANG HAIBO MACHINERY

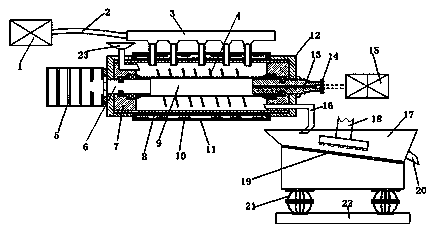

Splitter plate chemical fiber raw material particle dryer

InactiveCN107726789AIncrease contact areaReduce areaDrying gas arrangementsDrying chambers/containersFiberEngineering

The invention relates to a dryer for chemical fiber raw material particles with a partition plate, which includes a negative pressure chamber, a drainage chamber, a drying chamber, a spray chamber and an air storage chamber; wherein the negative pressure chamber includes a negative pressure tank, which is connected to the On the bottom end of the drainage cavity, the top end of the drainage cavity is provided with a damper; the drying cavity is connected to the top of the drainage cavity through the damper, and the bottom of the drying cavity is provided with a discharge port; the inside of the drying cavity is provided with a drying tray, and the drying tray The upper linear array is provided with a number of partitions connected by rotation. The inner wall of the drying chamber is also symmetrically equipped with a top push rod and a bottom push rod. The end of the top push rod is connected to the spring plate A, and the end of the bottom push rod is connected to B. , the spring plate A and the spring plate B are connected to the bottom support plate; the injection chamber is connected to the top of the drying chamber, the side wall of the injection chamber is provided with a feed pipe, the bottom of the injection chamber is provided with a support plate, and an array of pressure relief valves is arranged on the support plate; The air chamber is located on the top of the injection chamber, and several heating plates are arranged in array in the air storage chamber.

Owner:杨芳

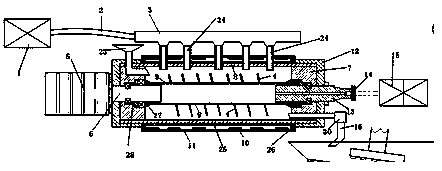

Chemical fiber material particle dryer

InactiveCN107726824AIncrease flat areaIncrease contact areaDrying gas arrangementsDrying solid materialsFiberDrive shaft

The invention relates to a chemical fiber material particle dryer. The chemical fiber material particle dryer comprises a negative-pressure cavity, a drainage cavity, a drying cavity, an injection cavity and an air storage cavity, wherein the negative-pressure cavity comprises a negative-pressure tank; the negative-pressure tank is connected to the bottom end of the drainage cylinder through a pressure limiting valve; the top end of the drainage cavity is provided with an air valve; the drying cavity is connected to the top of the drainage cavity through the air valve; the bottom of the dryingcavity is provided with a discharge port; the drying cavity is internally provided with a drying basket; the two transverse ends of the drying basket are connected to the drying cavity through driving shafts; a plurality of netlike partition boards are arranged in the drying basket in a linear array mode; the injection cavity is connected to the top of the drying cavity; the sidewall of the injection cavity is provided with a feed pipe, and the bottom of the injection cavity is provided with a supporting plate; a plurality of pressure relief valves are arrayed on the supporting plate; the airstorage cavity is connected to the top of the injection cavity and communicates with the injection cavity; an opening of the air storage cavity is covered with the supporting plate; a plurality of heating plates are arrayed in the air storage cavity; and the sidewall of the air storage cavity is provided with air inlet valves.

Owner:杨芳

Method for measuring coverage rate of quantum dot surface ligand

ActiveCN109932378AGuaranteed SolubilityGuaranteed stabilityAnalysis using nuclear magnetic resonancePhotovoltaic energy generationSolubilityCoffee ring effect

The invention provides a method for measuring the coverage rate of a quantum dot surface ligand, thereby realizing quality evaluation of quantum dots. If Ki is less than 2*10<-10> mol / cm<2>, the quality of the quantum dot is poor; and solution or ink configuration can not be carried out until the Ki value is improved. With the provided method, the result is accurate; and the operation is simple. Furthermore, with the method, the high stability of the quantum dot surface ligand content is ensured; the solubility of different batches of quantum dots is guaranteed; a coffee ring effect caused bydifferent drying rates in quantum dot solution preparation for a film is avoided; add the pixel resolution and uniformity of the brightening voltage and the photoelectric efficiency of the quantum dotdisplay panel can be improved.

Owner:TCL CORPORATION

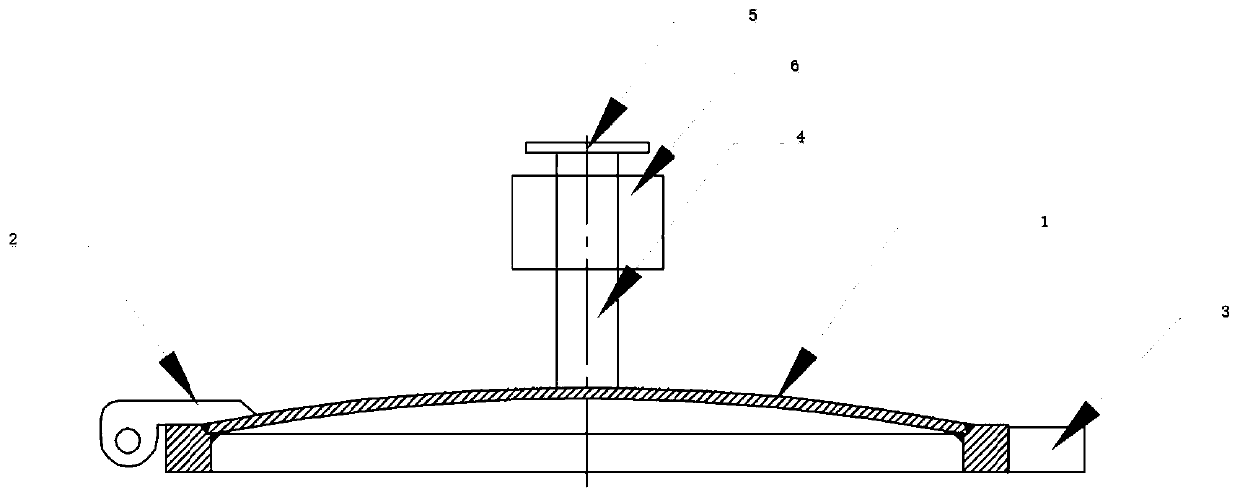

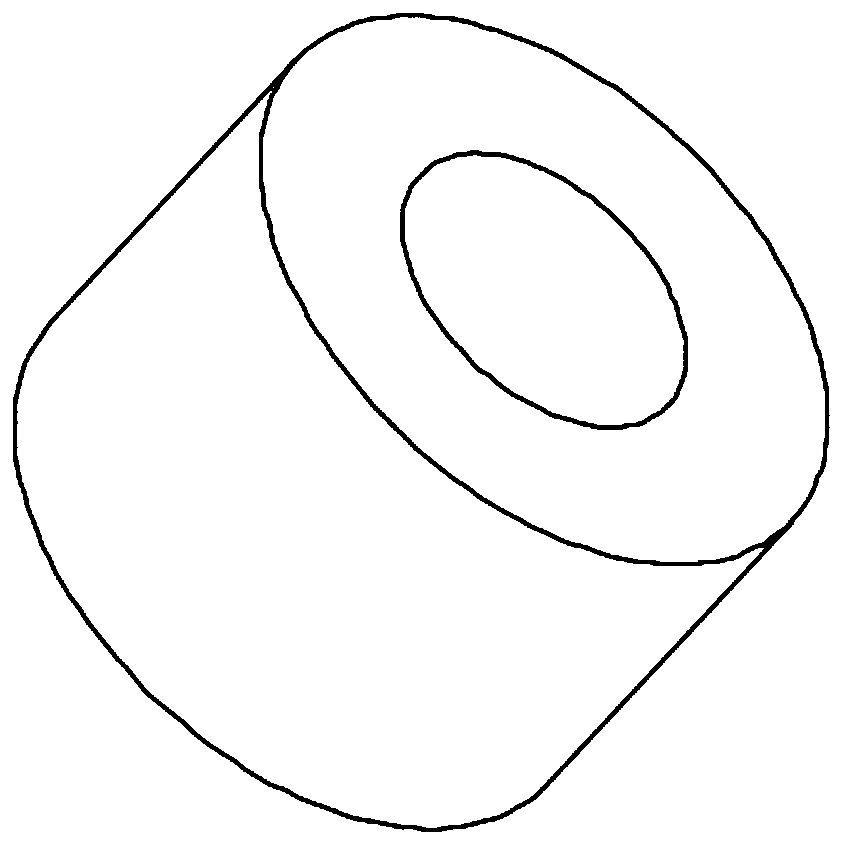

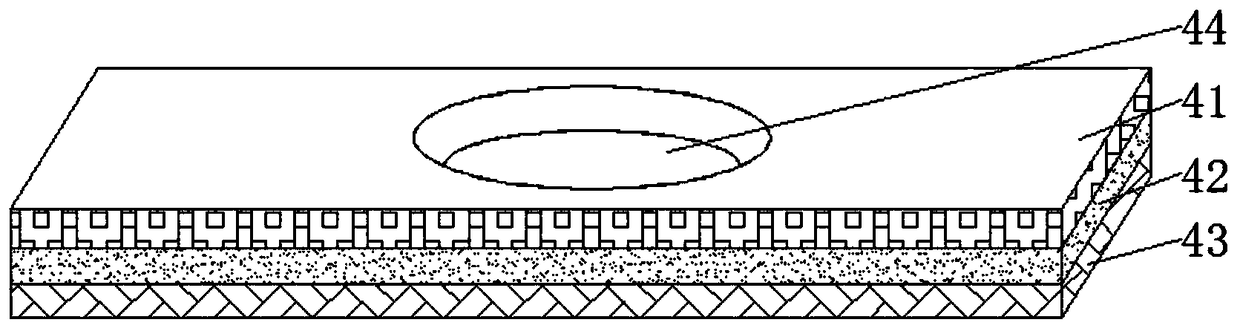

End cover for double-cone drying cylinder

PendingCN110793311AGuaranteed drying rateReduce wasteDrying solid materialsStructural engineeringMechanical engineering

The invention discloses an end cover for a double-cone drying cylinder. The end cover comprises a cover body, a hinge, a lug, a sliding rod, a limiting baffle and a heavy hammer. The cover body is rotationally connected with the double-cone drying cylinder through the hinge. The cover body is fixedly connected with the double-cone drying cylinder through the lug. The sliding rod is vertically arranged on the cover body. The heavy hammer is slidably arranged on the sliding rod, and the limiting baffle is arranged at the end of the sliding rod so as to prevent the heavy hammer from sliding out of the sliding rod. The sliding rod and the heavy hammer are additionally installed, though rotation of the double-cone drying cylinder, the heavy hammer is driven to hit the cover body ceaselessly, materials adhering to the cover body fall into the double-cone drying cylinder, then the drying rate of the materials is ensured, and material waste is reduced. A buffer mechanism is additionally arranged on the sliding rod, the heavy hammer is prevented from directly hitting the limiting baffle, and service life of the limiting baffle is prolonged. In addition, the end cover is simple in structure,low in manufacturing cost, high in universality and suitable for any double-cone dryers.

Owner:TAICANG ZHENGXIN DRYING EQUIP TECH

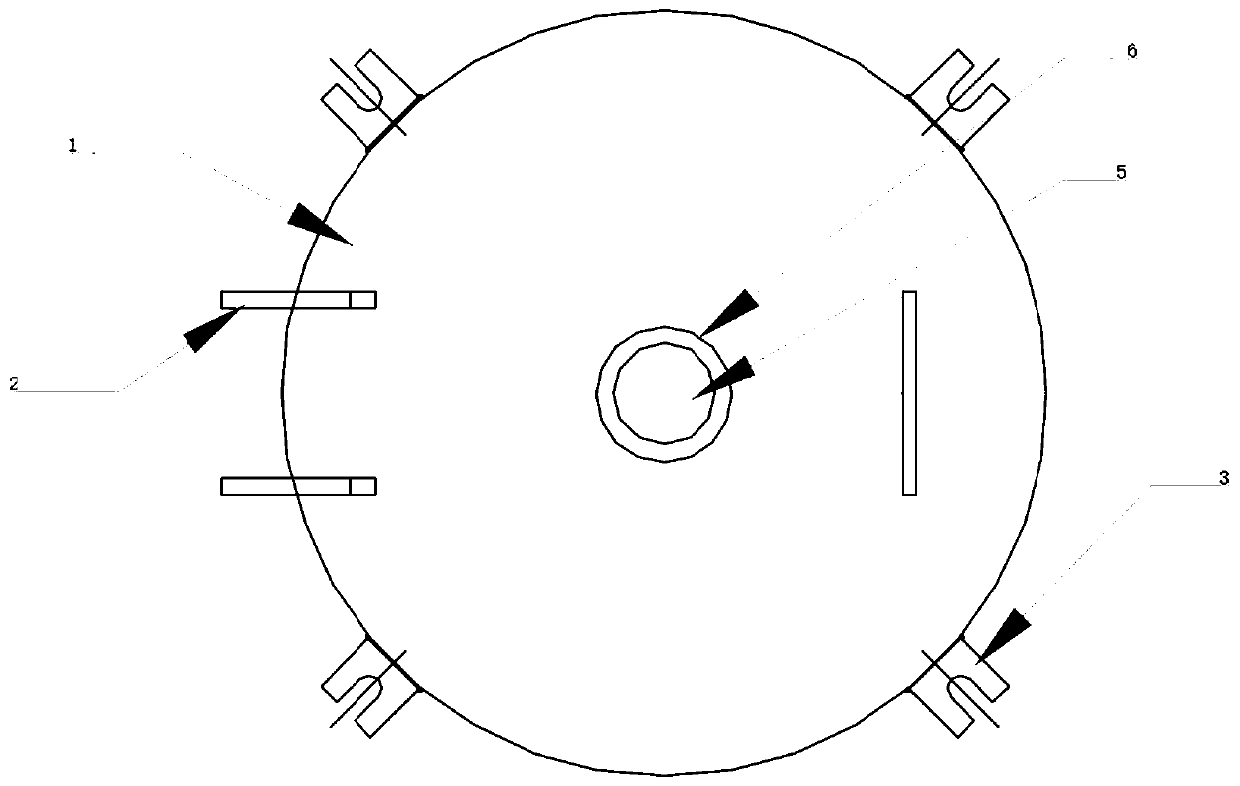

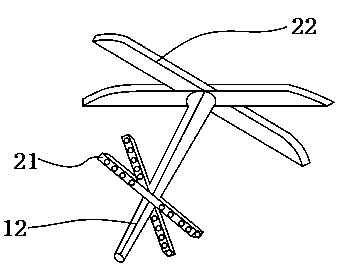

Airing device for tea leaves

InactiveCN111165599AReduce churnEasy to dryPre-extraction tea treatmentClimate change adaptationMechanical engineeringTea leaf

The invention discloses an airing device for tea leaves. The device comprises an airing disc, a rotating plate, a fixed seat and a bottom plate, a fixed seat is mounted at the top of the bottom plate,a servo motor is mounted in the center of the bottom end in the fixed seat, the output end of the servo motor extends to the top of the fixed seat and is provided with the rotating plate, first electric telescopic parts are evenly installed at the two ends of the top of the rotating plate, the output ends of the first electric telescopic parts are all hinged to and fixed to the bottom of the airing disc arranged above the rotating plate, and a transparent cover is hinged to and fixed to the center of the top of the airing disc through a fixing block. The device is provided with the airing disc, the rotating plate, the fixed seat and the bottom plate, and the top of the rotating plate is provided with the airing disc through the first electric telescopic parts, so that different angles areformed between the airing disc and the rotating plate by adjusting the expanding and contracting of the first electric telescopic parts. According to the device, the rotating plate conveniently rotates to drive the airing disc to rotate along with the sun motion trail, it is conveniently guaranteed that the airing disc makes full contact with sunlight for airing, and the device is convenient to use.

Owner:孝昌县孝孟种植专业合作社

Method for measuring content of quantum dot surface ligand and quantum dot ink preparing method

InactiveCN109932274AGuaranteed uniformityGuaranteed SolubilityWeighing by removing componentPreparing sample for investigationSolubilityCoffee ring effect

The invention provides a method for measuring the content of quantum dot surface ligand and a quantum dot ink preparing method. When the method is used for preparing quantum dot ink, the uniformity ofquantum dot ink quality can be ensured, the consistency of the solubility, drying rates and coffee ring effects of different batches of quantum dot ink is guaranteed, and the pixel resolution and uniformity of the lighting voltages and photoelectric efficiency of the quantum dot display panel are improved.

Owner:TCL CORPORATION

Method for measuring ligand content on quantum dot surface and preparation method for quantum dot ink

ActiveCN109932405BGuaranteed uniformityGuaranteed SolubilityChemical analysis using titrationMaterial electrochemical variablesChemical physicsCoffee ring effect

The invention provides a method for measuring the ligand content on the surface of the quantum dot and a preparation method for the quantum dot ink. The quantum dot ink preparation method of the present invention is used to configure the quantum dot ink, which can ensure the uniformity of the quality of the quantum dot ink, and can ensure that the solubility, drying rate and coffee ring effect of different batches of quantum dot ink are the same, and can improve the quality of the quantum dot ink. The uniformity of pixel resolution, turn-on voltage, and photoelectric efficiency of the display panel.

Owner:TCL CORPORATION

Method for measuring content of quantum dot surface ligand and quantum dot ink preparing method

ActiveCN109932285AGuaranteed uniformityGuaranteed SolubilityMaterial analysisSolubilityCoffee ring effect

The invention provides a method for measuring the content of quantum dot surface ligand and a quantum dot ink preparing method. When the method is used for preparing quantum dot ink, the uniformity ofquantum dot ink quality can be ensured, the consistency of the solubility, drying rates and coffee ring effects of different batches of quantum dot ink is guaranteed, and the pixel resolution and uniformity of the lighting voltages and photoelectric efficiency of the quantum dot display panel are improved.

Owner:TCL CORPORATION

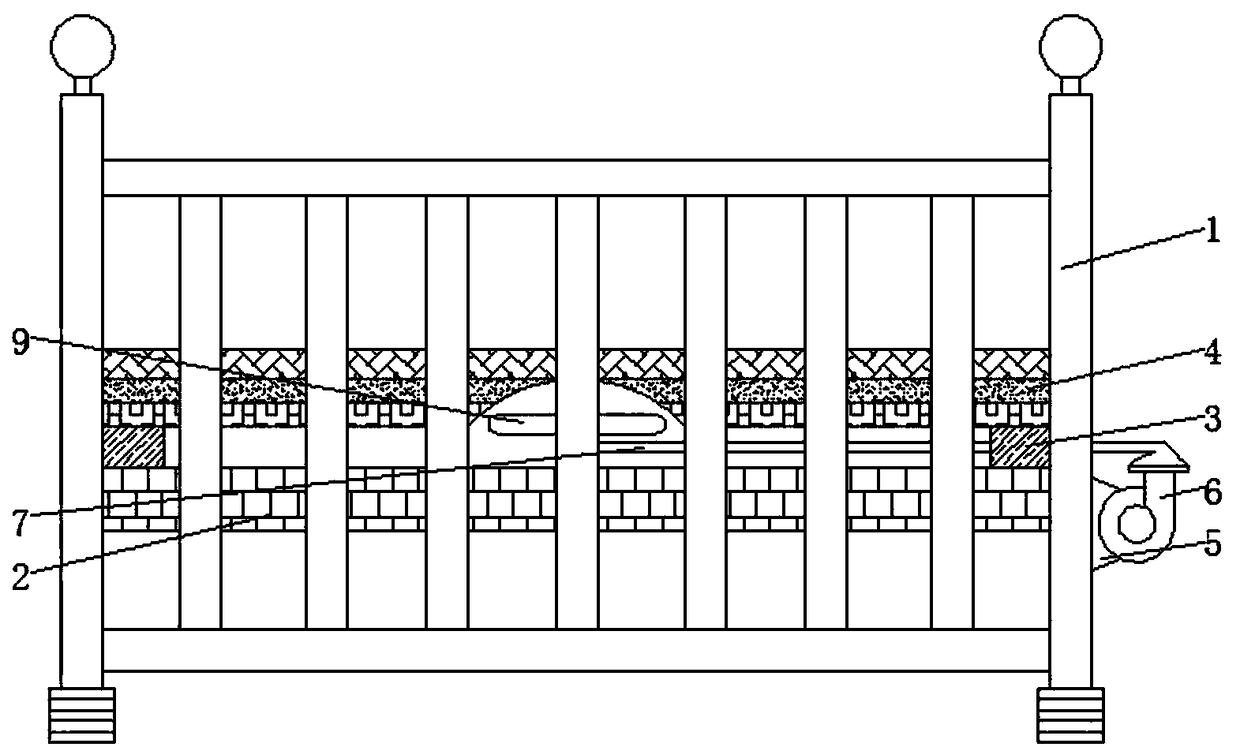

Human body water absorbing pad for infant crib

InactiveCN108968519AImprove water absorptionQuick dryingChildren furnitureActivated carbonHuman body

The invention discloses a human body water absorbing pad for an infant crib. The infant crib comprises a bed body, wherein a bed board is fixedly arranged at the inner side of the bed body; connectingplates are fixedly arranged at two sides of the top of the bed board; a mattress is arranged at the top of the connecting plates; the mattress comprises a base plate; the bottom of the base plate makes into contact with the top of the connecting plates; an activated carbon layer is fixedly arranged at the top of the base plate; a water-absorbent resin layer is fixedly arranged at the top of the activated carbon layer, and a conical opening is formed between the activated carbon layer and the base plate; a mounting base is fixedly arranged at one side of the bed body; a blasting fan is fixedlyarranged at one side of the mounting base; a connecting pipe is welded on an air vent of the blasting fan; a socketed pipe sleeves the top of the connecting pipeline; and a spraying nozzle is weldedat the top of the socketed pipe. According to the human body water absorbing pad provided by the invention, by arranging the activated carbon layer and the water-absorbent resin layer in cooperation with the blasting fan, the connecting pipeline and the spraying nozzle, the mattress is rapider in water-absorbing performance, so that urine of babies can be dried more rapidly.

Owner:嘉兴马德沙贸易有限公司

Quantum dot surface ligand content measuring method and quantum dot ink preparation method

ActiveCN109946331ASimple methodWide range of applicationsMaterial analysis using wave/particle radiationInksSolubilityPhotoelectric efficiency

The invention provides a quantum dot surface ligand content measuring method and a quantum dot ink preparation method. When the method is adopted to prepare the quantum dot ink, the uniformity of thequality of the quantum dot ink can be ensured, the solubility, the drying rate and the coffee ring effect of the quantum dot ink in different batches can be ensured to be the same, and the uniformityof the pixel resolution, the turn-on voltage and the photoelectric efficiency of the quantum dot display panel can be improved.

Owner:TCL CORPORATION

A method for measuring the coverage of ligands on the surface of quantum dots

ActiveCN109932357BGuaranteed SolubilityGuaranteed stabilityAnalysis by thermal excitationPhotovoltaic energy generationChemical physicsCoffee ring effect

The invention provides a method for measuring the ligand coverage on the surface of quantum dots, which can be used for quality assessment of quantum dots. If K i less than 2*10 ‑10 mol / cm 2 , the quality of quantum dots is not good, and K i Increase the value before proceeding with applications such as solution or ink dispensing. Adopt this method to determine quantum dot surface ligand coverage rate, result is accurate, easy to operate, further, can guarantee the stability of quantum dot surface ligand content by the method of the present invention, can guarantee the solubility of different batches of quantum dots, avoid The coffee ring effect caused by the different drying rates when the quantum dot solution is prepared into a film can improve the uniformity of the pixel resolution, turn-on voltage, and photoelectric efficiency of the quantum dot display panel.

Owner:TCL CORPORATION

Waste residue collecting device for ardealite processing and using method of waste residue collecting device

PendingCN114653721AGuaranteed crushing effectGuaranteed collectionSolid waste disposalTransportation and packagingElectric machineryEngineering

The invention discloses a waste residue collecting device for ardealite processing and a using method thereof.The waste residue collecting device comprises a treatment box, a feeding hopper, a motor and a smashing roller, the feeding hopper is installed in the middle of the upper end of the treatment box, the motor is installed on one side wall of the treatment box, and the smashing roller is arranged between the two side walls in the treatment box; electric sliding rails are fixed to the two side walls in the treatment box. The phosphogypsum crushing device has the beneficial effects that the electric sliding rail, the electric push rod, the brush and the access cover are arranged, in the crushing process, the brush can automatically sweep phosphogypsum waste residues adhered to the surfaces of the crushing rollers, manual cleaning is not needed, the crushing effect and the collection amount of phosphogypsum are guaranteed, the electric push rod ascends through the electric sliding rail, and the crushing efficiency is improved. And the brush is arranged below the access cover through the electric push rod, and then the access cover is opened, so that the brush can be conveniently replaced, the cleaning effect of the brush is ensured, and the practicability of the device is improved.

Owner:汉江城建集团有限公司

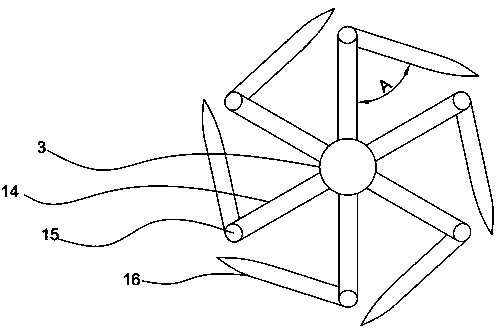

Flos chrysanthemi indici dryer

InactiveCN108413709AImprove wear resistanceKeep dryDrying gas arrangementsPreliminary solid treatment for dryingFlos chrysanthemiDrying

The invention provides a flos chrysanthemi indici dryer, and belongs to the field of food drying. The flos chrysanthemi indici dryer comprises an air heater and a first drying chamber; an exhaust holeand a feed port are formed in the upper end of the first drying chamber, and are respectively positioned at the two ends of the first drying chamber; a motor is arranged at the upper end of the firstdrying chamber; a control panel is arranged at the upper end of the motor; the motor is connected with an output end and a rotating shaft; the rotating shaft is of a hollow structure, and is providedwith a comprehensive stirring device, and one end is connected with the air heater through an air pipe; the lower end of the first drying chamber is connected with a second drying chamber; the seconddrying chamber is connected with the air heater through a main air pipe; a stirring rod is arranged in the second drying chamber; a filter screen is arranged below the stirring rod; through arrangement of the first and second drying chambers, flos chrysanthemi indici is repeatedly dried, so that the drying rate of the flos chrysanthemi indici is guaranteed; and the device is simple in structure and convenient to operate, has the functions of automatic crushing, drying and screening, and is suitable for large-scale popularization and production.

Owner:浦江海璞食品科技有限公司

Tasty siberian solomonseal rhizome polysaccharide pine nuts and preparation method thereof

InactiveCN107348444AImprove the immunityPromote secretionNatural extract food ingredientsFood dryingLycopeneRadix Rehmanniae Preparata

The invention discloses tasty siberian solomonseal rhizome polysaccharide pine nuts and a preparation method thereof. The tasty pine nuts are prepared from the following components in parts by weight: 1000-1200 parts of pine nuts, 500-550 parts of siberian solomonseal rhizomes, 13-15 parts of radix rehmanniae preparata, 13-15 parts of radix rehmanniae, 16-18 parts of red dates, 18-20 parts of Chinese wolfberries, 13-15 parts of bark of oriental variegated coralbean, 13-15 parts of cassia bark, 13-15 parts of green Chinese prickly ash, 13-15 parts of radix angelicae sinensis, 13-15 parts of rhubarb roots, 300-350 parts of cheese powder, and 13-15 parts of lycopene. The tasty siberian solomonseal rhizome polysaccharide pine nuts are crispy in taste, uniform in quality, and bright in luster, and cause no excessive internal heat for regular eating of the pine nuts. The beneficial components contained in the pine nuts have the efficacy of enhancing immunity.

Owner:HEFEI RUILIAN BIOTECH CO LTD

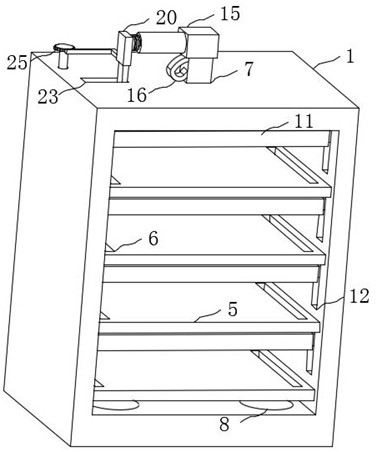

A cardboard drying device for paper product processing

ActiveCN113405333BImprove flatnessGuaranteed aestheticsDrying solid materials without heatDrying gas arrangementsCardboardIndustrial engineering

The invention discloses a cardboard drying device for paper product processing, which comprises a drying box and a box door. A plurality of storage boards are fixedly installed in the drying box, and each storage board is provided with two ventilation slots. , there are a plurality of pressing plates slidingly connected in the drying box, and each pressing plate is located above the corresponding storage plate, and a plurality of lifting blocks are fixedly installed on the side wall of each pressing plate, and the drying box A plurality of lifting grooves are opened on the inner wall, and each lifting groove is respectively matched with a corresponding lifting block. The advantage is that in the process of drying the cardboard, the air pressure change caused by the evaporation of water on the cardboard can be used to drive the pressure plate to move down to complete the extrusion of the cardboard, thereby improving the flatness of the cardboard after drying and ensuring the cardboard in the later stage. The use effect and the aesthetic level, and the driving method for controlling the movement of the pressing plate does not require manual control, nor does it need to set up an additional power device, which achieves automatic and energy-saving effects.

Owner:南通力人健身器材有限公司

Method for measuring coverage rate of quantum dot surface ligand

ActiveCN109932373AGuaranteed SolubilityGuaranteed stabilityMaterial analysis using wave/particle radiationPhotovoltaic energy generationPhysicsSolubility

The invention provides a method for measuring the coverage rate of a quantum dot surface ligand, thereby realizing quality evaluation of quantum dots. If Ki is less than 2*10<-10> mol / cm<2>, the quality of the quantum dot is poor; and solution or ink configuration can not be carried out until the Ki value is improved. With the provided method, the quantum dot surface ligand coverage rate is determined; the result is accurate; and the operation is simple. Furthermore, with the method, the high stability of the quantum dot surface ligand content is ensured; the solubility of different batches ofquantum dots is guaranteed; a coffee ring effect caused by different drying rates in quantum dot solution preparation for a film is avoided; add the pixel resolution and uniformity of the brighteningvoltage and the photoelectric efficiency of the quantum dot display panel can be improved.

Owner:TCL CORPORATION

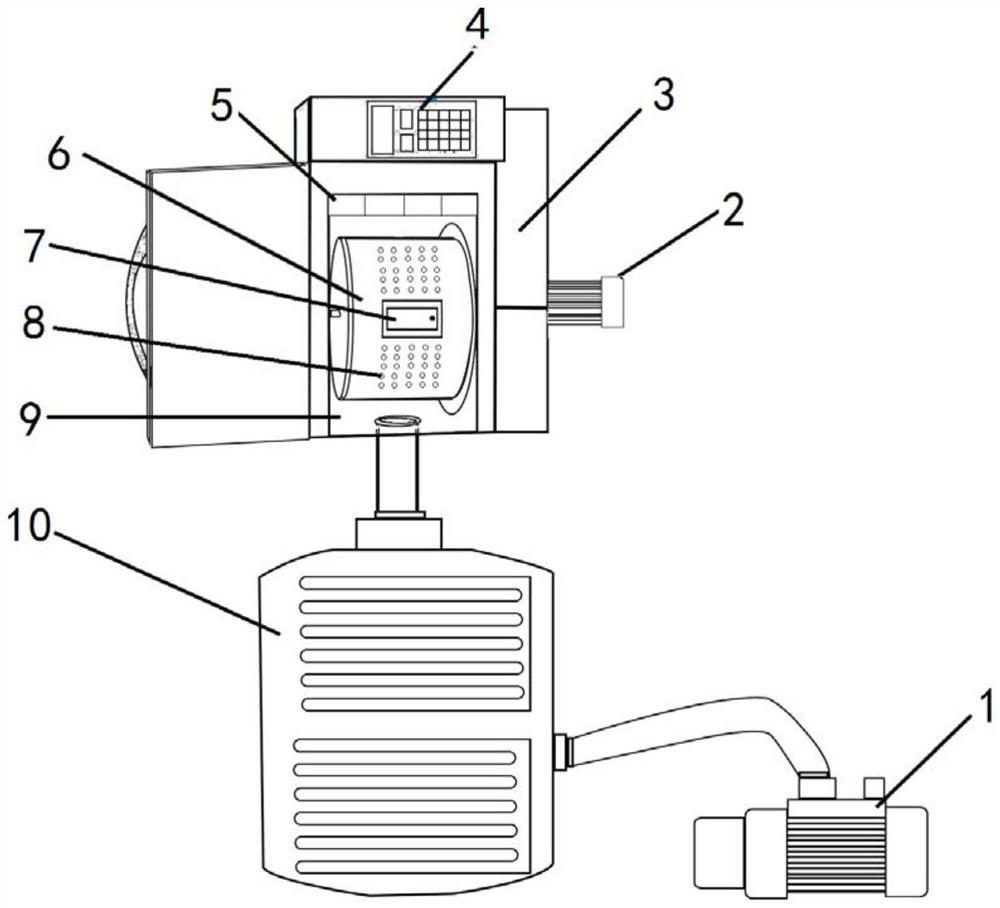

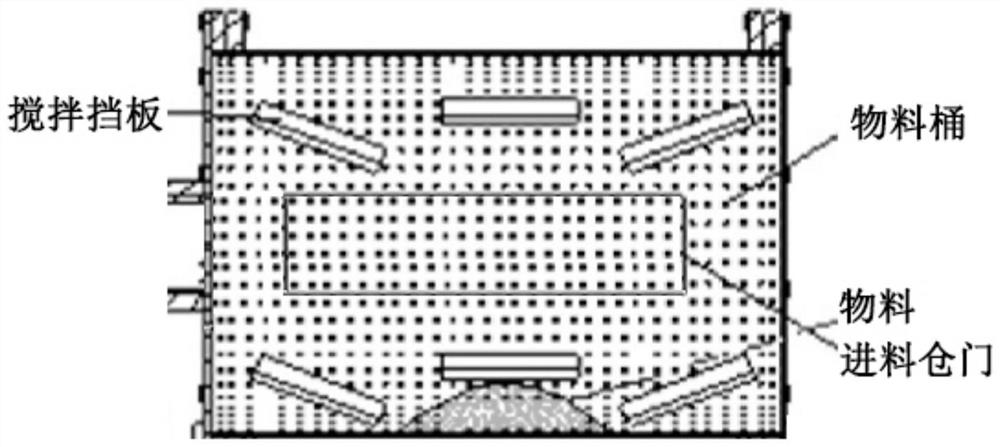

Energy-saving and efficient fruit and vegetable dewatering and drying equipment and drying method

PendingCN114375987AGuaranteed drying rateGuaranteed energy savingFood processingFruits/vegetable preservation by dehydrationTemperature controlProcess engineering

The invention belongs to the technical field of fruit and vegetable drying, and particularly relates to energy-saving and efficient fruit and vegetable dewatering and drying equipment and a drying method. The material barrel is connected with a temperature control cold trap box, and the temperature control cold trap box is connected with a vacuum pump and an adjustable-speed motor; a cabin door and an optical fiber sensor are arranged on the barrel wall of the material box; the microwave generator is placed above the material barrel; the optical fiber sensor, the temperature control cold trap box, the microwave generator, the vacuum pump and the motor are regulated and controlled through the control panel; stirring baffles are distributed in the material barrel; drying equipment is improved, microwaves are added together with rotation, uniform drying is achieved, meanwhile, the drying rate is increased, and energy is saved; meanwhile, the invention provides a process method for drying fruits and vegetables by using the equipment, microwave freezing and uniform heating are realized through an intermittent stirring mode, and the product quality is ensured.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

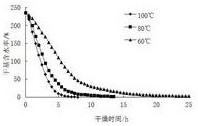

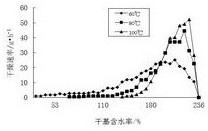

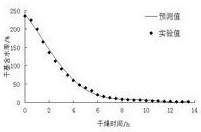

Hot air drying preservation method for myrtle fruits

PendingCN112970835AGuaranteed drying rateGuarantee product qualityFood processingDesign optimisation/simulationRHODOMYRTUS TOMENTOSA FRUITProcess engineering

The invention discloses a preservation method for myrtle fruits. A hot air drying method is adopted to dry fresh myrtle fruits. The myrtle fruits have no obvious constant rate period during hot air drying at more than 80 DEG C, and the lower drying temperature, the longer drying time is needed. a hot air drying mathematical model of the fresh myrtle fruits is established by adopting the form of least squares polynomial, and the correlation of the model can reach more than 0.999. The predicting value of the model is highly identical with an experimental value, so that the model has high reliability. Through comparison of drying products and energy consumption under different temperatures, the optimal drying temperature is 80 DEG C. The method adopted to preserve the myrtle fruits can guarantee product quality while guaranteeing drying rate, and can also achieve the purpose of saving energy consumption.

Owner:HEZHOU UNIV

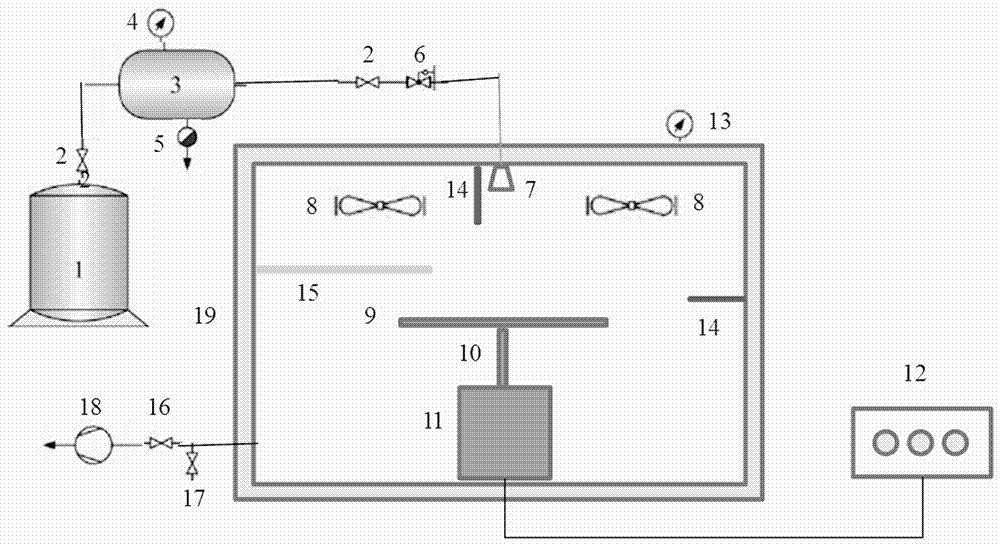

Ultrasonic enhanced low-pressure superheated steam drying device and method

InactiveCN105004150BReduced risk of thermal decompositionAccelerate evaporationDrying using combination processesDrying gas arrangementsBoiling pointUltrasonic radiation

The invention relates to a drying device and method using contact ultrasound to strengthen low-pressure superheated steam. The device is equipped with a drying box connected with a vacuum pump, a boiler, a steam storage tank, an ultrasonic generator, an ultrasonic transducer and an ultrasonic radiation plate , the boiler is connected to the steam storage tank through a conduit, the steam storage tank is connected to the drying box through a conduit, and a steam injection port is provided in the drying box at the connection point, the ultrasonic transducer is arranged in the drying box, and the drying box is connected to the drying box through a wire. The ultrasonic generator outside the box is connected, and the ultrasonic radiation plate is set on the ultrasonic transducer; this method uses low-pressure superheated steam as the drying medium, on the one hand, the boiling point of the water in the material is reduced through the low pressure, which is conducive to the evaporation of water, on the one hand, it is different from the normal Compared with high-pressure superheated steam, the use of low-pressure superheated steam reduces the drying temperature, thereby reducing the risk of thermal decomposition of active ingredients to a certain extent, while ensuring a higher drying rate.

Owner:HENAN UNIV OF SCI & TECH

A method for measuring the coverage of ligands on the surface of quantum dots

ActiveCN109932373BGuaranteed SolubilityGuaranteed stabilityMaterial analysis using wave/particle radiationPhotovoltaic energy generationChemical physicsCoffee ring effect

The invention provides a method for measuring the ligand coverage on the surface of quantum dots, which can be used for quality assessment of quantum dots. If K i less than 2*10 ‑10 mol / cm 2 , the quality of quantum dots is not good, and K i Increase the value before proceeding with applications such as solution or ink dispensing. Adopt this method to determine quantum dot surface ligand coverage rate, result is accurate, easy to operate, further, can guarantee the stability of quantum dot surface ligand content by the method of the present invention, can guarantee the solubility of different batches of quantum dots, avoid The coffee ring effect caused by the different drying rates when the quantum dot solution is prepared into a film can improve the uniformity of the pixel resolution, turn-on voltage, and photoelectric efficiency of the quantum dot display panel.

Owner:TCL CORPORATION

Determination method of quantum dot surface ligand content and quantum dot ink preparation method

ActiveCN109932285BGuaranteed uniformityGuaranteed SolubilityMaterial analysisChemical physicsCoffee ring effect

Owner:TCL CORPORATION

A vegetable dehydration sub-section drying box

ActiveCN105494608BImprove qualityGuaranteed drying rateFood processingDrying machines with non-progressive movementsPulp and paper industryAir blower

The invention discloses a vegetable dehydration subsection drying box which comprises a hot blast heater, a drying box body, a first drying area, a second drying area, a third drying area and a steam drying device. An air outlet of the hot blast heater is provided with an air inlet pipeline, air blowers are mounted on the left sides of the tops of inner cavities of the first drying area, the second drying area and the third drying area respectively, and anemographs are arranged at the lower ends of the air blowers. The steam drying devices are mounted in the middles of the tops of the inner cavities of the first drying area, the second drying area and the third drying area respectively, and steam drying pipes are arranged in inner cavities of the steam drying devices. An efficient heat pump is mounted on the right side of the drying box body, an air draft pipeline is mounted at the right side of the efficient heat pump, and exhaust fans are mounted on the right sides of the tops of the inner cavities of the first drying area, the second drying area and the third drying area respectively. Through the subjection drying mode, the quality of dried vegetables is improved, manpower cost is reduced, and work efficiency is high.

Owner:FUJIAN MINQING MINHUA IND & TRADE

Method for measuring coverage rate of quantum dot surface ligand

ActiveCN109932357AGuaranteed SolubilityGuaranteed stabilityAnalysis by thermal excitationPhotovoltaic energy generationPhysicsImage resolution

The invention provides a method for measuring the coverage rate of a quantum dot surface ligand, thereby realizing quality evaluation of quantum dots. If Ki is less than 2*10<-10> mol / cm<2>, the quality of the quantum dot is poor; and solution or ink configuration can not be carried out until the Ki value is improved. With the provided method, the result is accurate; and the operation is simple. Furthermore, with the method, the high stability of the quantum dot surface ligand content is ensured; the solubility of different batches of quantum dots is guaranteed; a coffee ring effect caused bydifferent drying rates in quantum dot solution preparation for a film is avoided; add the pixel resolution and uniformity of the brightening voltage and the photoelectric efficiency of the quantum dotdisplay panel can be improved.

Owner:TCL CORPORATION

A method for measuring the coverage of ligands on the surface of quantum dots

ActiveCN109932378BGuaranteed SolubilityGuaranteed stabilityAnalysis using nuclear magnetic resonancePhotovoltaic energy generationChemical physicsCoffee ring effect

The invention provides a method for measuring the ligand coverage on the surface of quantum dots, which can be used for quality assessment of quantum dots. If K i less than 2*10 ‑10 mol / cm 2 , the quality of quantum dots is not good, and K i Increase the value before proceeding with applications such as solution or ink dispensing. Adopt this method to determine quantum dot surface ligand coverage rate, result is accurate, easy to operate, further, can guarantee the stability of quantum dot surface ligand content by the method of the present invention, can guarantee the solubility of different batches of quantum dots, avoid The coffee ring effect caused by the different drying rates when the quantum dot solution is prepared into a film can improve the uniformity of the pixel resolution, turn-on voltage, and photoelectric efficiency of the quantum dot display panel.

Owner:TCL CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com