Double-chamber differential pressure type microwave vacuum freeze drying equipment

A technology of microwave vacuum and drying equipment, which is applied in the direction of drying solid materials, lighting and heating equipment, and combination of methods to dry solid materials, etc., which can solve the problems of reducing drying rate and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

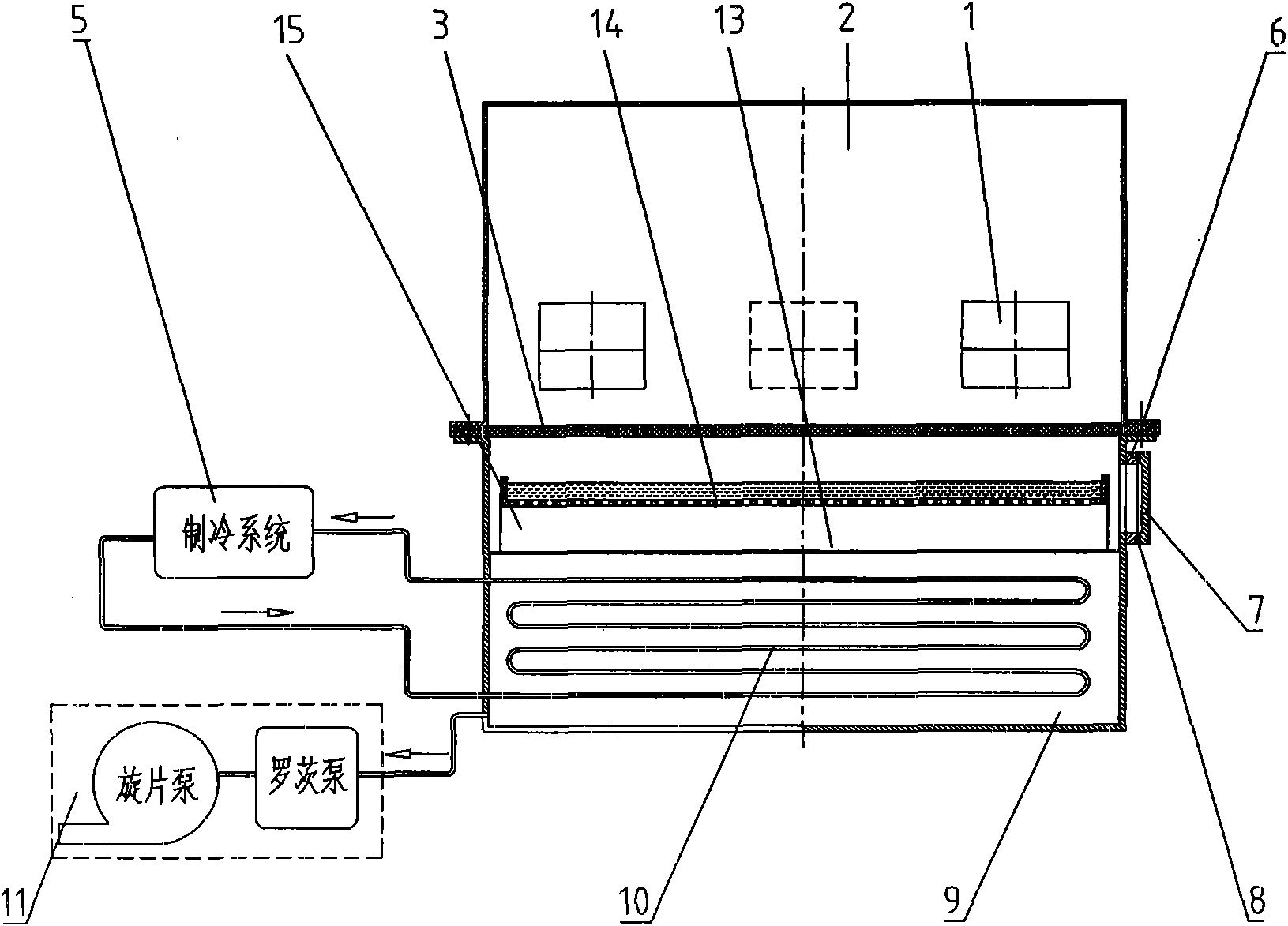

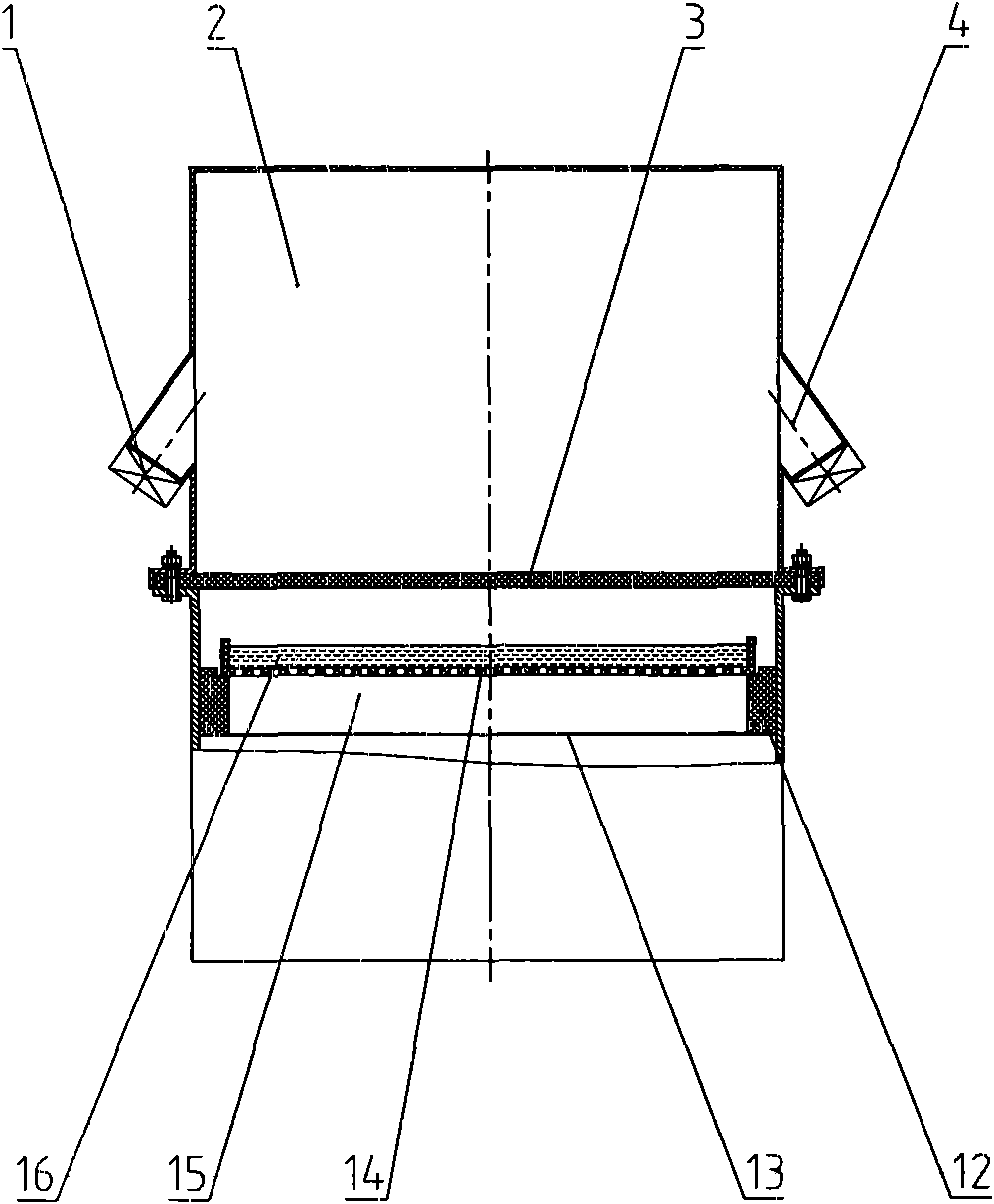

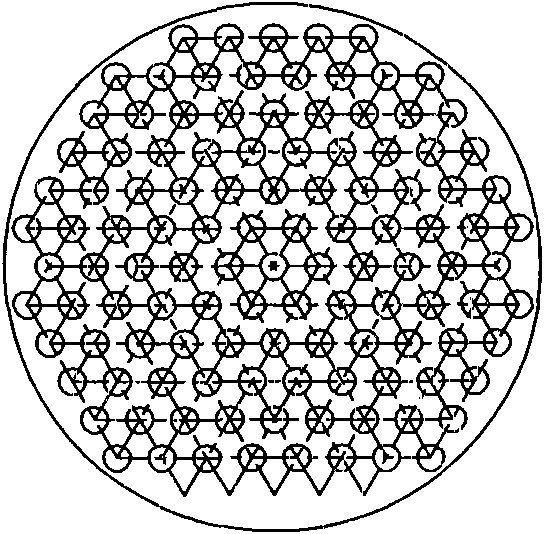

[0018] The double chamber body differential pressure type microwave vacuum freeze-drying equipment of the present embodiment is as figure 1 and figure 2 As shown, the upper rectangular chamber body is divided into an upper first chamber 2 and a lower second chamber 15 by a horizontally arranged polytetrafluoroethylene material transmission partition plate 3 . The side of the first chamber 2 is provided with an upwardly inclined microwave feeding device, which is composed of an upwardly inclined microwave feeding port 4 and a magnetron 1 placed at its end. Therefore, microwaves can be emitted to the top of the first chamber 2, and through reflection, the first chamber 2 becomes an ideal resonant cavity. The inside of the first chamber 2 is normal pressure (research shows that the absolute vacuum degree should be less than the discharge critical value of 3000Pa).

[0019] The material carrying device in this embodiment is a material tray 14 supported on the guide rails 12 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com