A kind of manufacturing method of multi-discharge cavity parallel discharge tube

A manufacturing method and discharge cavity technology, applied in the field of discharge tubes, can solve problems such as hidden dangers, easy damage to air gaps and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

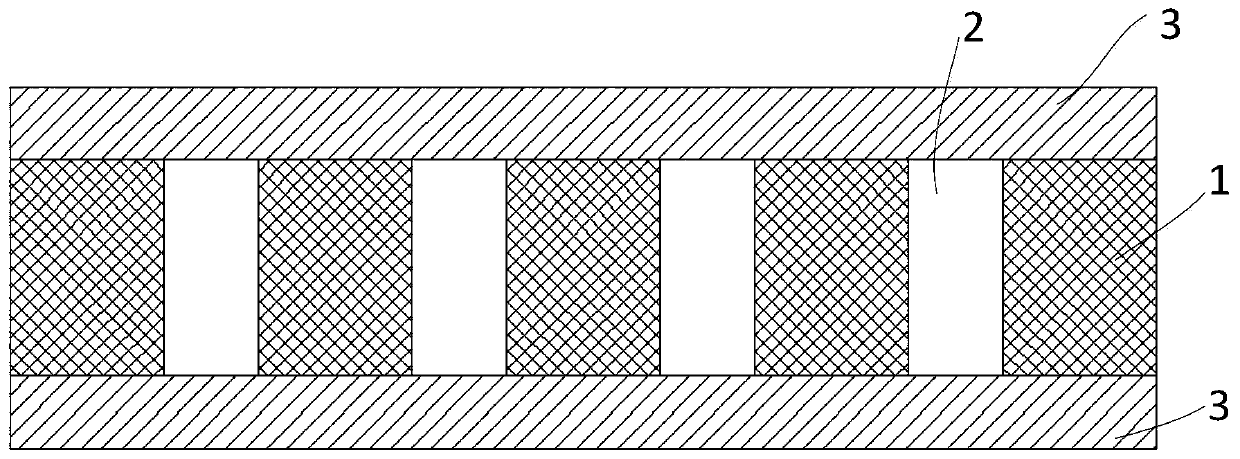

[0023] Such as figure 1 As shown, a discharge tube with multiple discharge chambers connected in parallel includes an insulator 1. Discharge electrodes 2 are respectively arranged at both ends of the insulator 1. Several discharge chambers 2 are arranged on the insulator 1. The discharge chambers 2 run through the insulator and connect the discharge electrodes 3 at both ends.

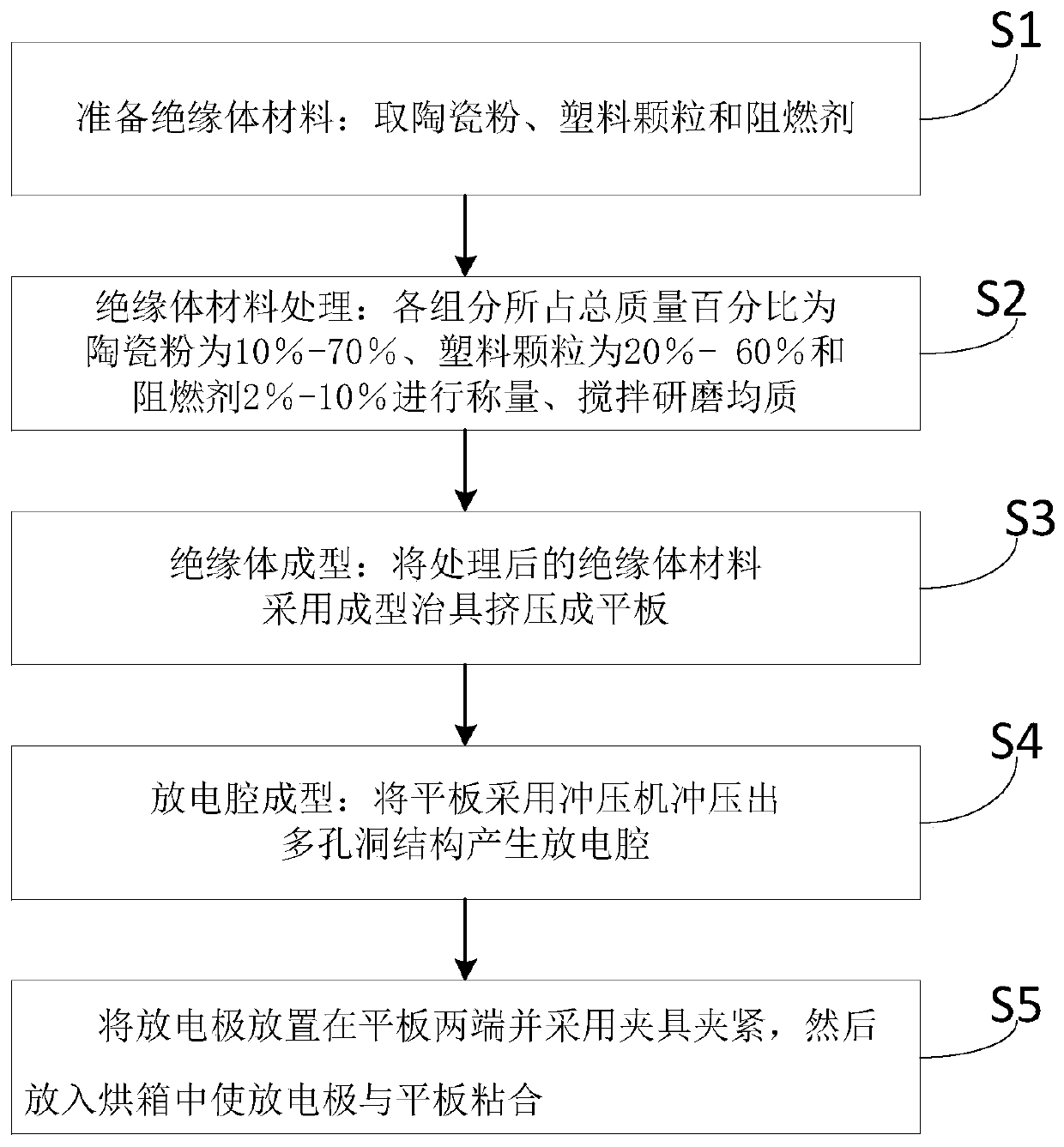

[0024] Such as figure 2 As shown, a method for manufacturing a multi-discharge chamber parallel discharge tube includes the following steps:

[0025] S1. Prepare the material of insulator 1: take ceramic powder, plastic particles and flame retardant;

[0026] S2. Material treatment of insulator 1: The total mass percentage of each component is 10%-70% for ceramic powder, 20%-60% for plastic particles and 2%-10% for flame retardant. Weigh, stir and grind for homogeneity ;

[0027] S3. Forming the insulator 1: extruding the processed insulator material into a flat plate with a forming jig;

[0028] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com