Flos chrysanthemi indici dryer

A wild chrysanthemum and dryer technology, which is applied in dryers, drying, biomass drying and other directions, can solve the problems of uneven drying of agricultural and sideline products, unsuitable for large-scale promotion, uncontrollable drying temperature, and the like. The effect of enhancing wear resistance, simple structure and increasing drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

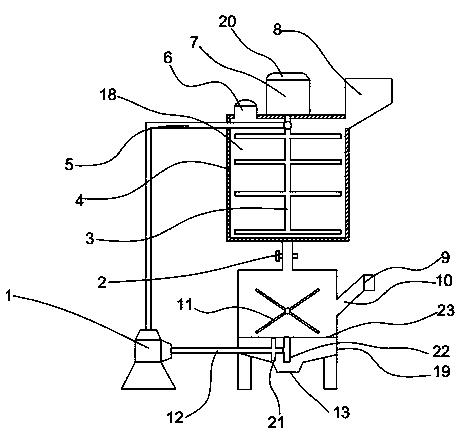

[0023] figure 1 Shown, the drying machine of wild chrysanthemum comprises hot air blower 1, the first drying chamber 18, and the first drying chamber 18 is a double-layer structure, built-in heating plate 4, and the first drying chamber 18 upper end is provided with air outlet 6 and the feed inlet 8 are respectively located at the two ends of the first drying chamber 18, the upper end of the first drying chamber 18 is provided with a motor 7, the upper end of the motor is provided with a control panel 20, the motor 7 is connected with the output end and the rotating shaft 3, and the rotating shaft 3 is Hollow structure, the shaft 3 is equipped with a comprehensive stirring device, and one end is connected to the hot air blower 1 through the air pipe 5, the lower end of the first drying chamber 18 is connected to the second drying chamber 19, and a control valve 2 is provided at the connection between the two. The second drying chamber 19 is connected with the hot air blower 1 ...

Embodiment 2

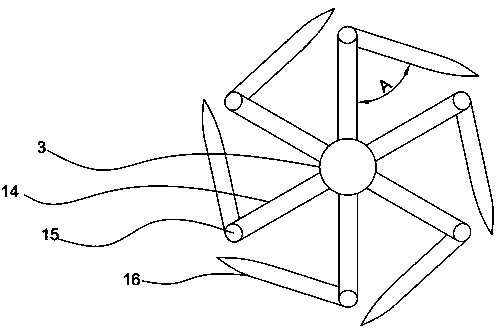

[0025] Such as Figure 3-5 As shown, the optimization scheme of this embodiment on the basis of embodiment 1 is:

[0026]The comprehensive mixing device includes a connecting rod 14, one end of the connecting rod 14 is connected with the rotating shaft 3, and the other end is connected with the support column 15, and the lower end of the support column 15 is connected with the automatic telescopic rod 16, and the two ends of the automatic telescopic rod 16 are blade-shaped, and the automatic telescopic rod 16 With connecting rod 14 both sides surface is provided with some through holes 17, is provided with filter screen on the through hole 17, connecting rod 14, support column 15, automatic expansion rod 16, rotating shaft 3 are hollow structures, drive connecting rod by the rotation of rotating shaft, The support column and the automatic telescopic rod rotate, and the blades on both sides of the upper end of the automatic telescopic rod can automatically chop the wild chrysan...

Embodiment 3

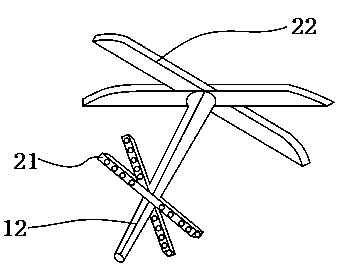

[0029] Such as figure 2 As shown, the optimization scheme of this embodiment on the basis of embodiment 1 is:

[0030] The main air pipe 12 is provided with an air distribution pipe 21, and the air distribution pipe 21 is provided with some ventilation holes, the end of the main air pipe 12 is connected with the rotating blade 22, the filter screen 23 is arranged vertically above the rotating blade 22, and the discharge port 13 is arranged below the rotating blade 22. By setting a number of ventilation holes on the air distribution pipe and connecting the rotating blades at the end of the main air pipe, the hot air in the air holes can dry the wild chrysanthemums. The filter screen perpendicular to it produces a certain shaking effect, preventing the wild chrysanthemums on the filter screen from being piled up and unable to fall. After drying, they are discharged from the outlet below.

[0031] The above-mentioned rotating blade is made of plastic material, and its formula i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com