Waste residue collecting device for ardealite processing and using method of waste residue collecting device

A collection device, phosphogypsum technology, applied in chemical instruments and methods, transportation and packaging, solid waste removal, etc., can solve problems such as reducing the practicability of the device, reducing the functionality of the device, affecting the drying rate of phosphogypsum, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings:

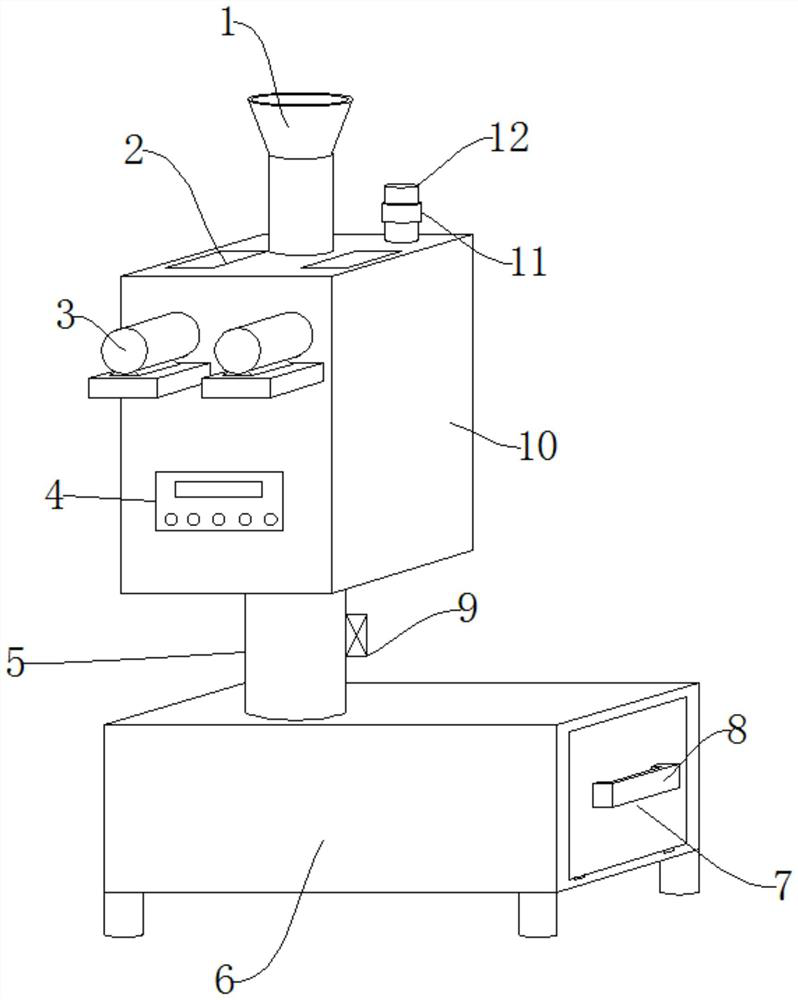

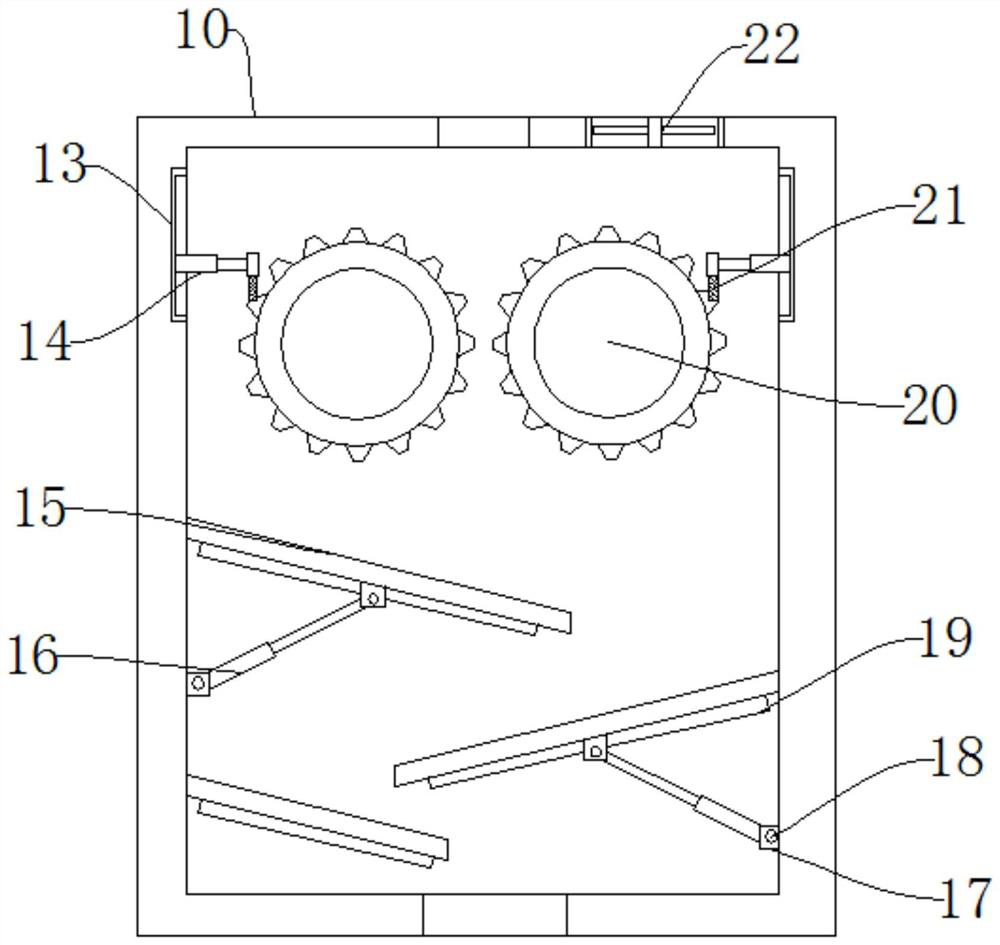

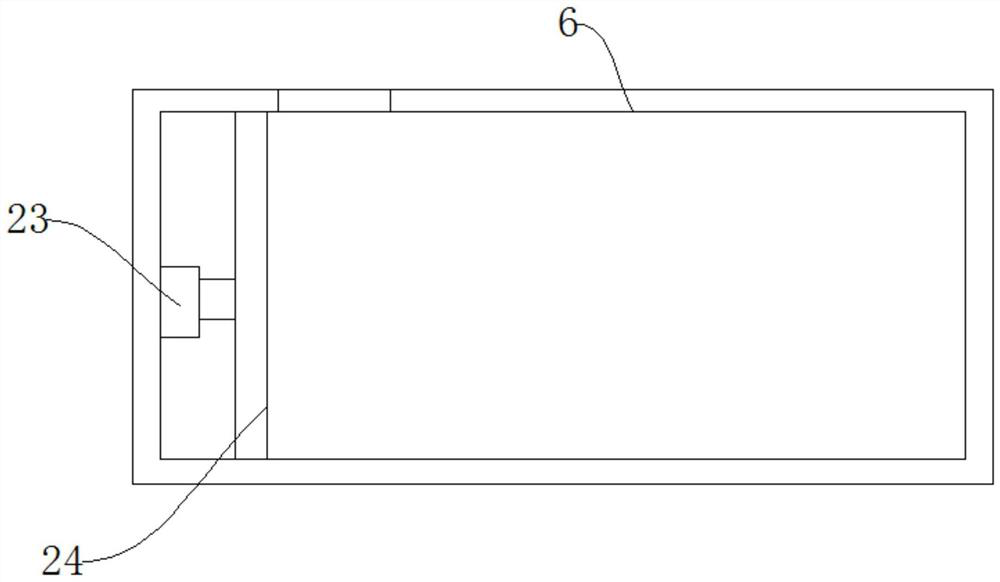

[0034] like Figure 1-Figure 4As shown, a waste slag collection device for phosphogypsum processing includes a processing box 10, a feeding hopper 1, a motor 3 and a pulverizing roller 20. The feeding hopper 1 is installed in the middle of the upper end of the processing box 10. The motor 3 is installed on one side wall of the processing box 10 , the pulverizing roller 20 is arranged between the inner two side walls of the processing box 10 , and electric sliding rollers are fixed on both the inner side walls of the processing box 10 . Rail 13, the electric sliding rail 13 is provided with an electric push rod 14, one end of the electric push rod 14 is provided with a brush 21, both sides of the feeding hopper 1 are provided with an inspection cover 2, the pulverizing roller 20 A deflector 15 is provided below, a heating plate 19 is installed at the bottom end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com