A cardboard drying device for paper product processing

A drying device and technology for paper products, applied in the field of paper product processing, can solve problems such as surface wrinkling and affecting the aesthetics of the use effect, and achieve the effects of improving flatness, ensuring the use effect and aesthetics, and ensuring the aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

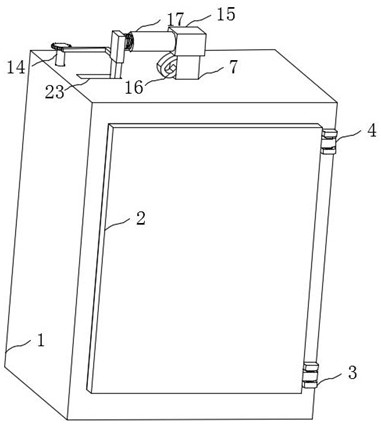

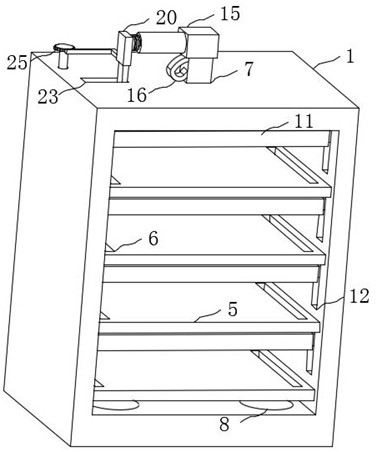

[0029] refer to Figure 1-3 , a cardboard drying device for paper product processing, including a drying box 1 and a box door 2, a plurality of storage boards 5 are fixedly installed in the drying box 1, and each storage board 5 is provided with two ventilation slots 6.

[0030] Of note above are:

[0031] 1. The storage board 5 is used to place the cardboard to be dried, and the design of the ventilation groove 6 on it facilitates the gas circulation in the drying box 1, thereby keeping the overall temperature in the drying box 1 consistent and ensuring its The drying effect of multiple cardboards inside.

[0032] 2. There are two sets of connecting blocks 3 fixedly installed on the front side wall of the drying box 1, and two connecting blocks 3 are fixedly installed on the side wall of the box door 2, and the two connecting blocks 3 are respectively connected to each other through the rotating shaft. The corresponding set of connection blocks 3 are connected by rotation,...

Embodiment 2

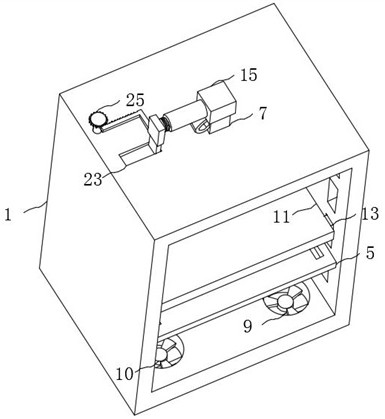

[0045] refer to Figure 6-9 , two front and rear symmetrical moving grooves 28 are provided on the side wall of the lower end of the pressing plate 11, and two moving blocks 27 are slidably connected in the two moving grooves 28, and each two moving blocks 27 corresponding to the front and rear positions are fixed. A paving roller 26 is installed.

[0046] Of note above are:

[0047] 1. The two flattening rollers 26 can move at the lower end of the pressing plate 11, so that the pressing plate 11 can be moved down first to drive the two flattening rollers 26 to contact the upper surface of the cardboard, and then the two flattening rollers can be moved The flat rollers 26 move away from each other and move from the center of the cardboard to both sides. At this time, the cardboard can be paved to further ensure the flatness of the surface of the cardboard after drying.

[0048] 2. Two-way lead screw 29 is rotatably connected in one of the moving grooves 28, and the two-way l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com