Vacuum drying device of stepping type ultrasonic cleaning machine and method thereof

A vacuum drying device and ultrasonic technology, applied in progressive dryers, drying gas layout, cleaning methods and utensils, etc., can solve the problems of large energy loss and general drying rate, and achieve improved drying rate, simple shielding effect, Guaranteed verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

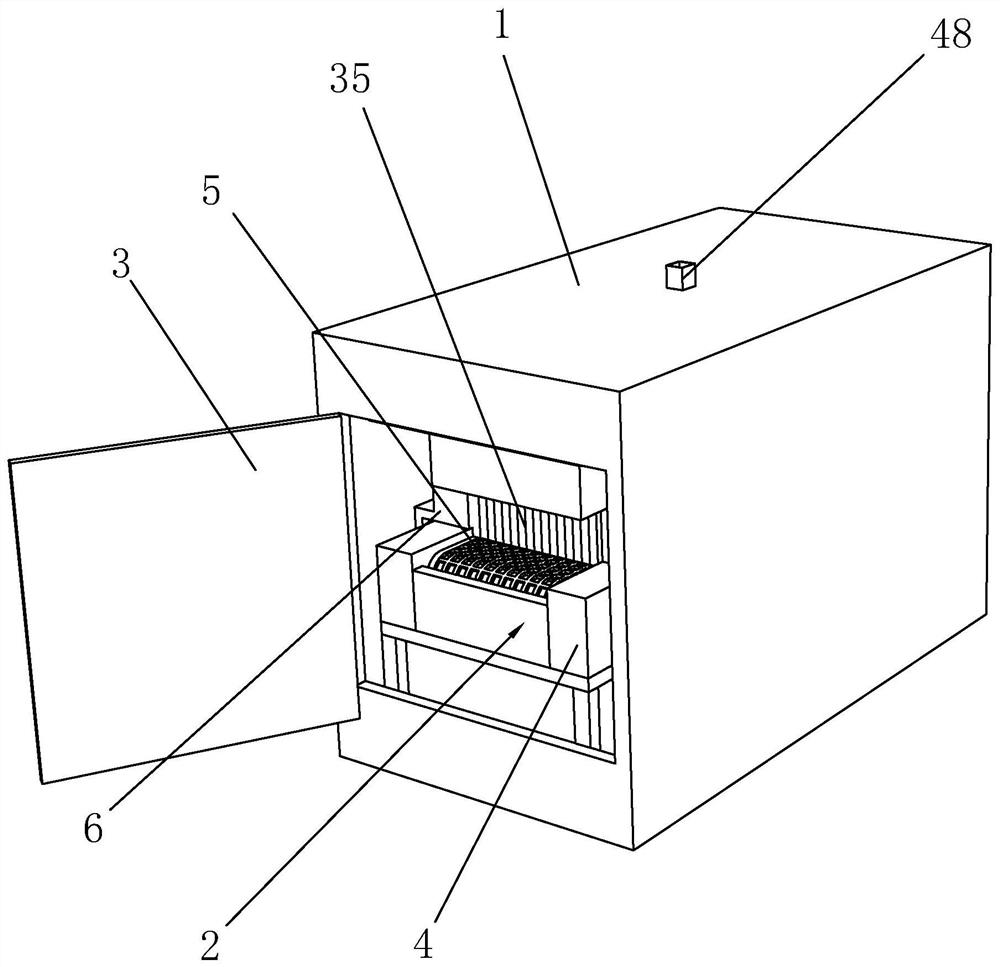

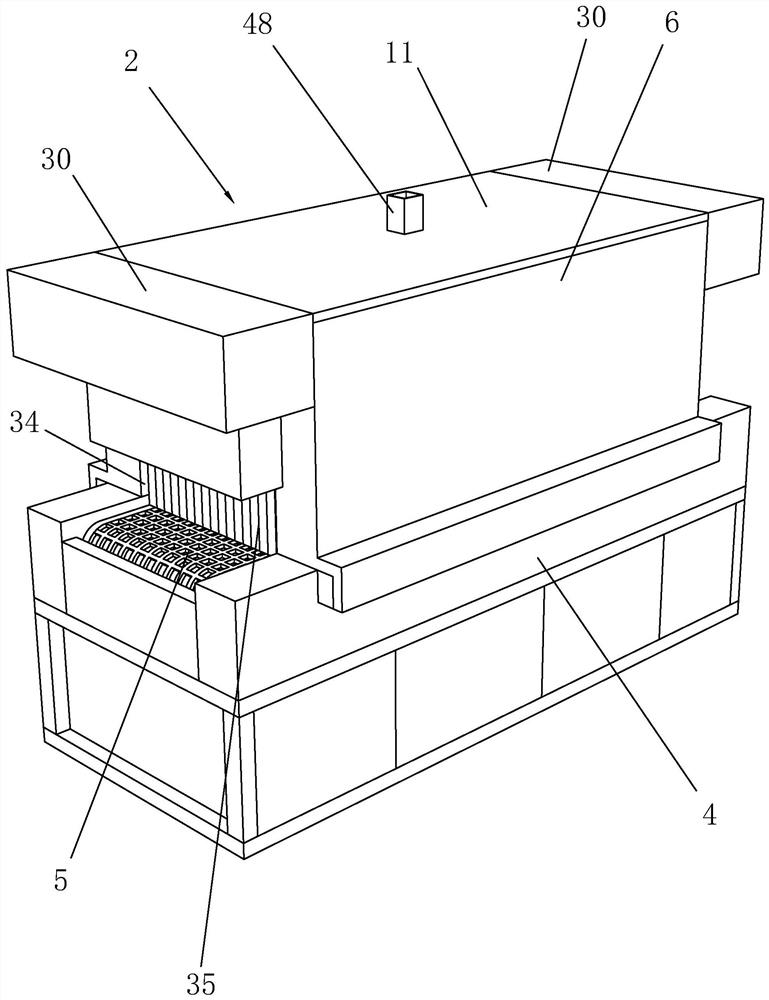

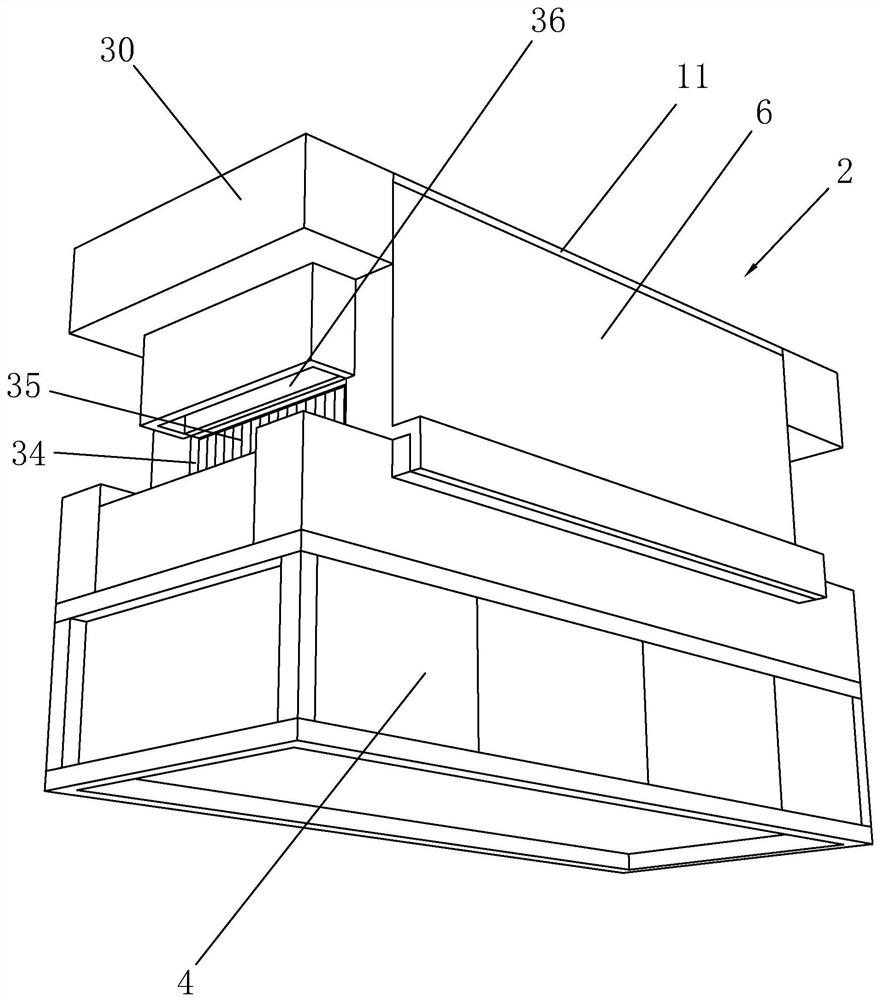

[0045] Such as Figure 1 to Figure 16 Shown is the vacuum drying device of the step-by-step ultrasonic cleaning machine of the present invention, which includes a sealed casing 1 and a drying mechanism 2. The front and rear ends of the sealed casing 1 are provided with sealed doors 3, and the drying mechanism 2 is located in the sealed casing 1. Drying Mechanism 2 comprises support 4, mesh belt conveying assembly 5, inner shell cover 6 and drying assembly 7, and mesh belt conveying assembly 5 is arranged in the support 4, and inner shell cover 6 is positioned at the upper middle part of mesh belt conveying assembly 5, and inner shell cover 6 An air guide cover 8 is arranged inside, and an opening adjustment assembly 10 is arranged on the bottom air outlet 9 of the air guide cover 8 , and the air guide pipe 48 at the top of the air guide cover 8 passes through the top cover plate 11 on the top surface of the inner shell cover 6 and the sealed shell 1 extends to the outside of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com