Insulating material for electrical machines

A technology of insulating materials and electrical equipment, applied in electrical components, transformer/inductor parts, circuits, etc., can solve the problems of damage to winding life, reduce power, etc., and achieve the effect of improving life, small mechanical load, and simple handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

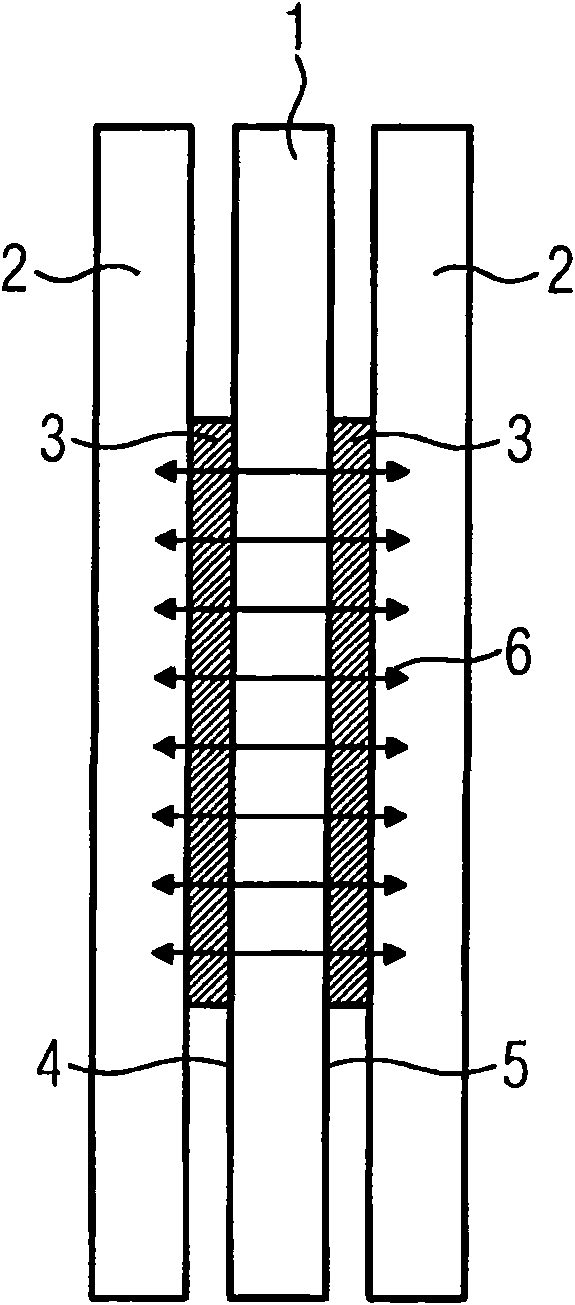

[0023] exist figure 1 A schematic diagram of the principle of force bonding connection of the present invention is shown in . An adhesive layer 3 is arranged on the carrier material 1 on the front side 4 and the rear side 5 . The adhesive layer 3 contacts the turns 2 in an insulated state by baking or bonding. Because the adhesive layers 3 lie directly or congruently opposite one another on the front side 4 and the rear side 5 of the carrier material 1 , a direct non-positive connection is formed between the respectively opposing adhesive layers 3 . As a result, no shear forces develop on the carrier material 1 since the forces are transmitted directly from one side to the other. Due to this direct force-bonding connection, the following advantages are obtained in particular:

[0024] - Baking or bonding of insulating material to turns 2 of electrical conductors of electrical equipment (eg transformers, transmitters, generators) results in high stability

[0025] - resulti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com