Constant wave system for acquiring uniform microwave fields and method for acquiring uniform microwave fields

A microwave field and uniform technology, applied in the field of microwave systems, can solve the problems affecting the reliability of item effect analysis results, the randomness of item effects, and inability to repeat, and achieve the effects of easy repeatability, high uniformity, and uniformity improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

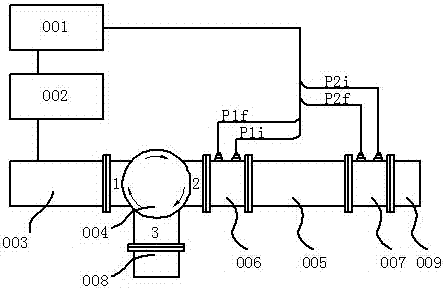

[0042] The present invention is realized through the following technical solutions: as figure 1 As shown, a constant wave system for obtaining a uniform microwave field includes a controller 001, a solid-state microwave source 002 connected through a waveguide, an exciter 003, a circulator 004, a first two-way directional coupler 006, and a second two-way directional coupler 007. Reactor 005. The first high-power matching load 008. The second high-power matching load 009.

[0043] The circulator 004 includes three ports connected to the first end of the exciter 003, the second end to feed the microwave into the reactor 005 through the first two-way directional coupler 006, and the third end to the first high-power matching load 008. A microwave source 002, an exciter 003, a circulator 004, a first bidirectional directional coupler 006, a reactor 005, a second bidirectional directional coupler 007, and a second high-power matching load 009 are connected in sequence.

[0044] T...

Embodiment 2

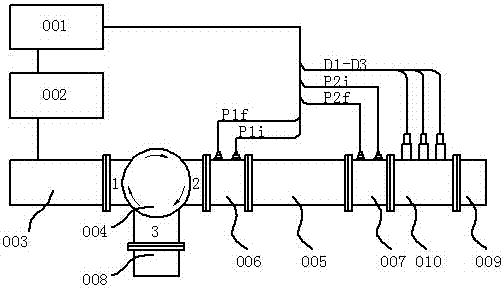

[0059] The present invention is realized through the following technical solutions: as figure 2 As shown, on the basis of Embodiment 1, an adjustable waveguide pin 010 is added.

[0060] A constant wave system for obtaining a uniform microwave field, including a controller 001, a solid-state microwave source 002 connected through a waveguide, an exciter 003, a circulator 004, a first two-way directional coupler 006, a second two-way directional coupler 007, and a reaction 005, the first high-power matching load 008, the second high-power matching load 009, and the adjustable waveguide pin 010.

[0061] The adjustable waveguide pin 010 is arranged between the second two-way directional coupler 007 and the first high-power matching load 008 . The adjustable waveguide pin 010 includes a three-pin adjuster for manually adjusting microwave reflected power and a rectangular waveguide matched with the three-pin adjuster.

[0062] The circulator 004 includes three ports connected t...

Embodiment 3

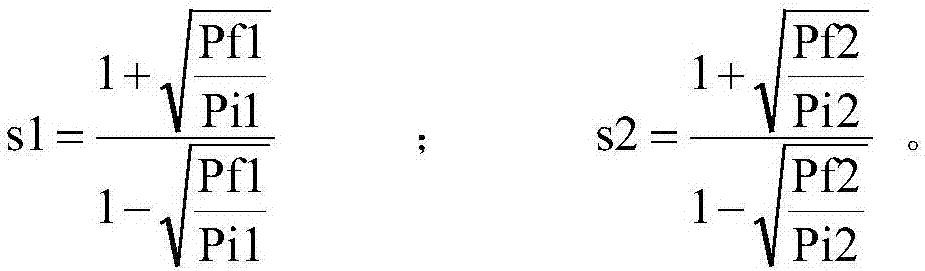

[0072] In this embodiment, on the basis of Embodiment 1 or 2, the method for obtaining the standing wave ratio s is further described. The first two-way directional coupler 006 collects the microwave input power Pi1 and the microwave reflected power Pf1 at the inlet port of the reactor 005, and at the same time The second two-way directional coupler 007 collects the microwave input power Pi2 and the microwave reflected power Pf2 at the outlet of the reactor 005, and a total of 4 signals are sent to the controller 001 for processing to analyze the standing wave ratio s of the microwave field in the resonant cavity of the reactor 005 Situation: If the standing wave ratio s satisfies 1<s≤1.2, the microwave field is uniform; otherwise, the microwave field is not uniform.

[0073] The use of directional couplers to collect power and the conversion relationship between input power, reflected power and standing wave ratio s are all existing technologies. This application only uses exi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com