A method for preparing a gate dielectric structure using ald

A technology of gate dielectric and equipment, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of insufficiency of devices, large gate leakage current, etc., and achieve the effect of uniform distribution and improved electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

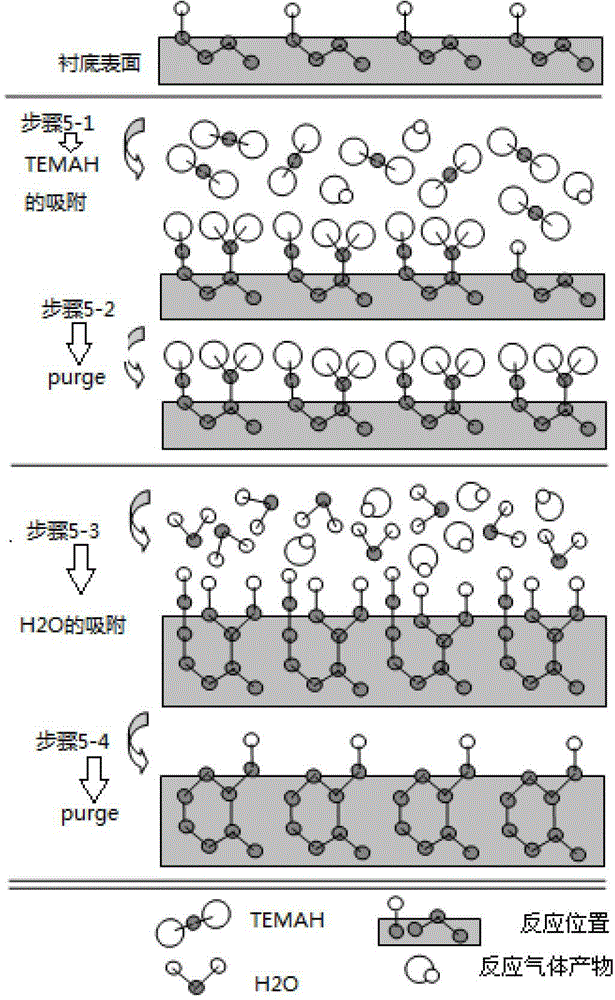

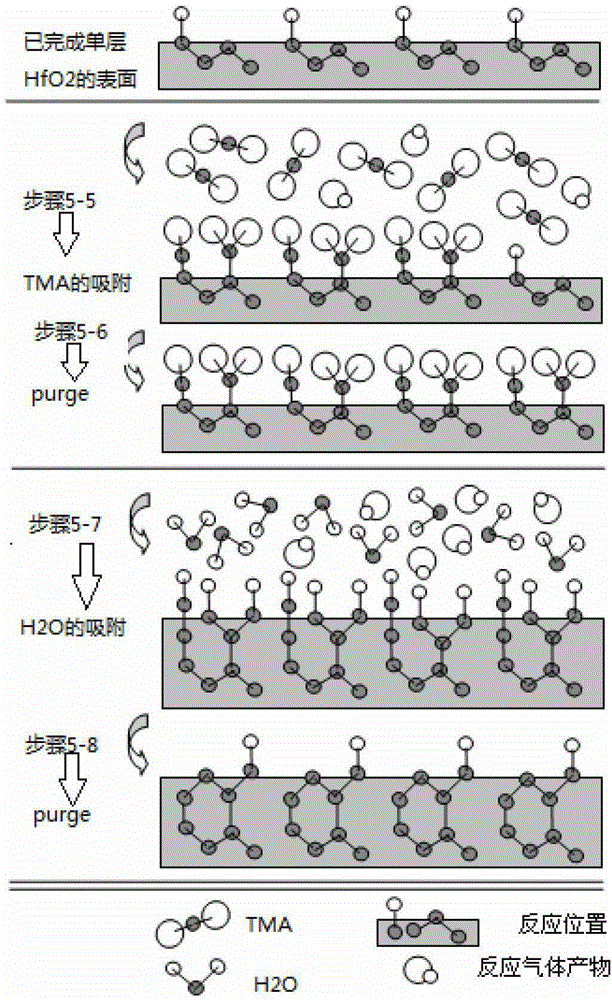

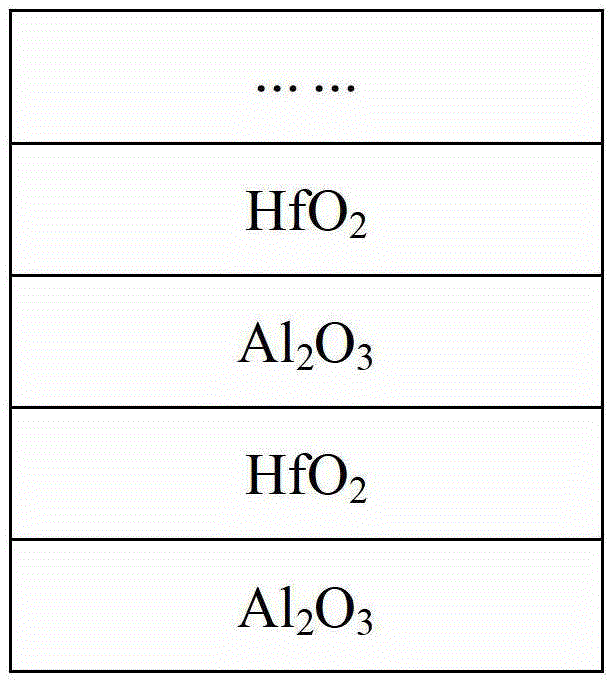

[0032] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0033] An embodiment of the present invention provides a method for preparing a gate dielectric structure using ALD, including the following steps:

[0034] Step 101, perform standard RCA cleaning on the substrate, using H 2 SO 4 :H 2 o 2 =5:100 Boil for 5 minutes; then rinse with deionized water (DIwater); then use HF:H 2 O=5:95 Soak for 2 minutes; use N at the end 2 blow dry;

[0035] Step 102, put the substrate into the chamber of the ALD equipment; vacuumize the chamber, and at the same time heat the peripheral parts of the ALD equipment that need to be heated; after the vacuum of the chamber is pumped below 1torr, the substrate is heating;

[0036] Step 103, through the carrier gas N 2 The tetramethylet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com