Chemical vapor deposition equipment

A technology of chemical vapor deposition and equipment, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of not being able to prepare ultra-large size body materials, etc., and achieve good vacuum tightness, reduced volume, and structure stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

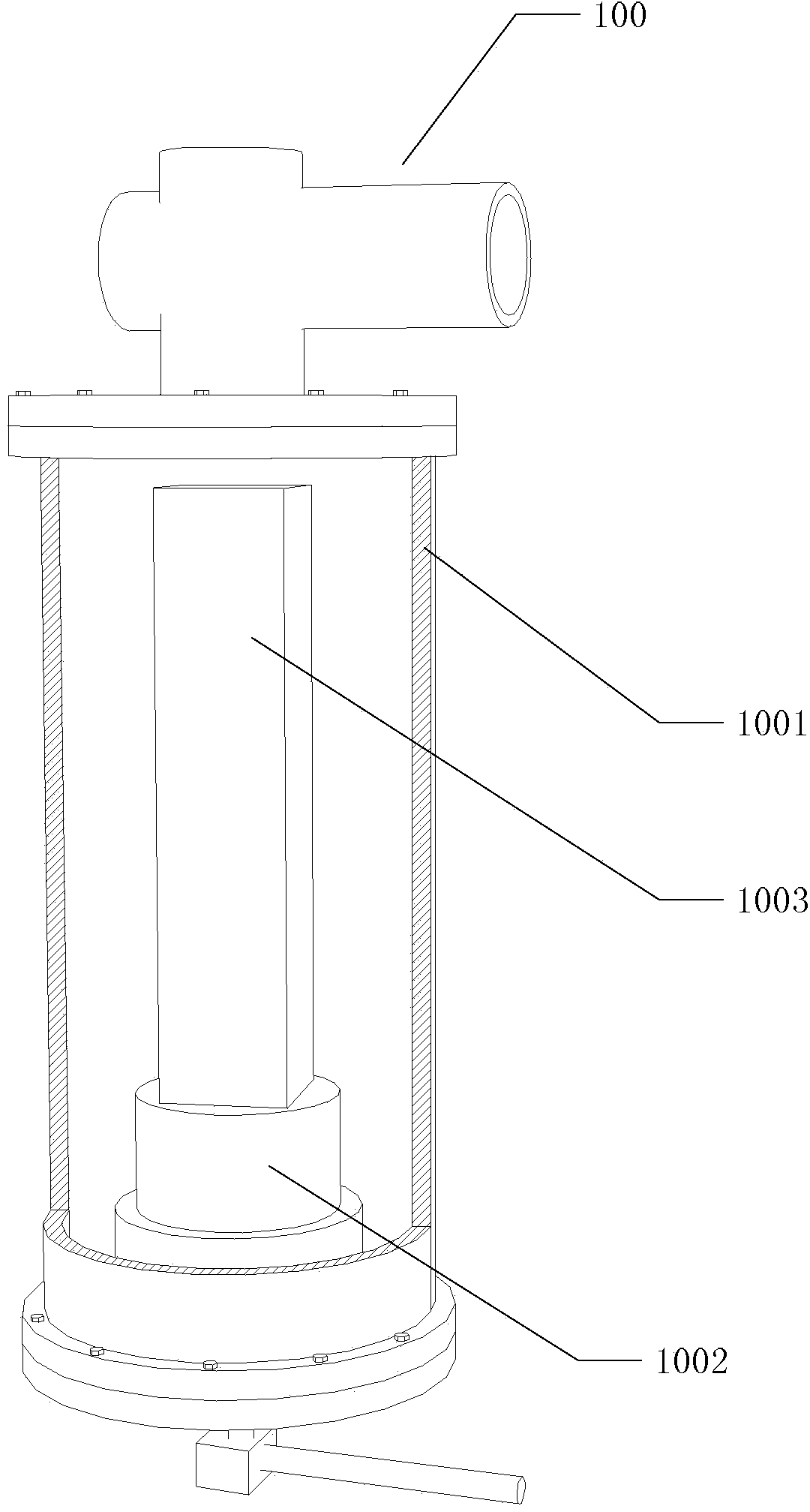

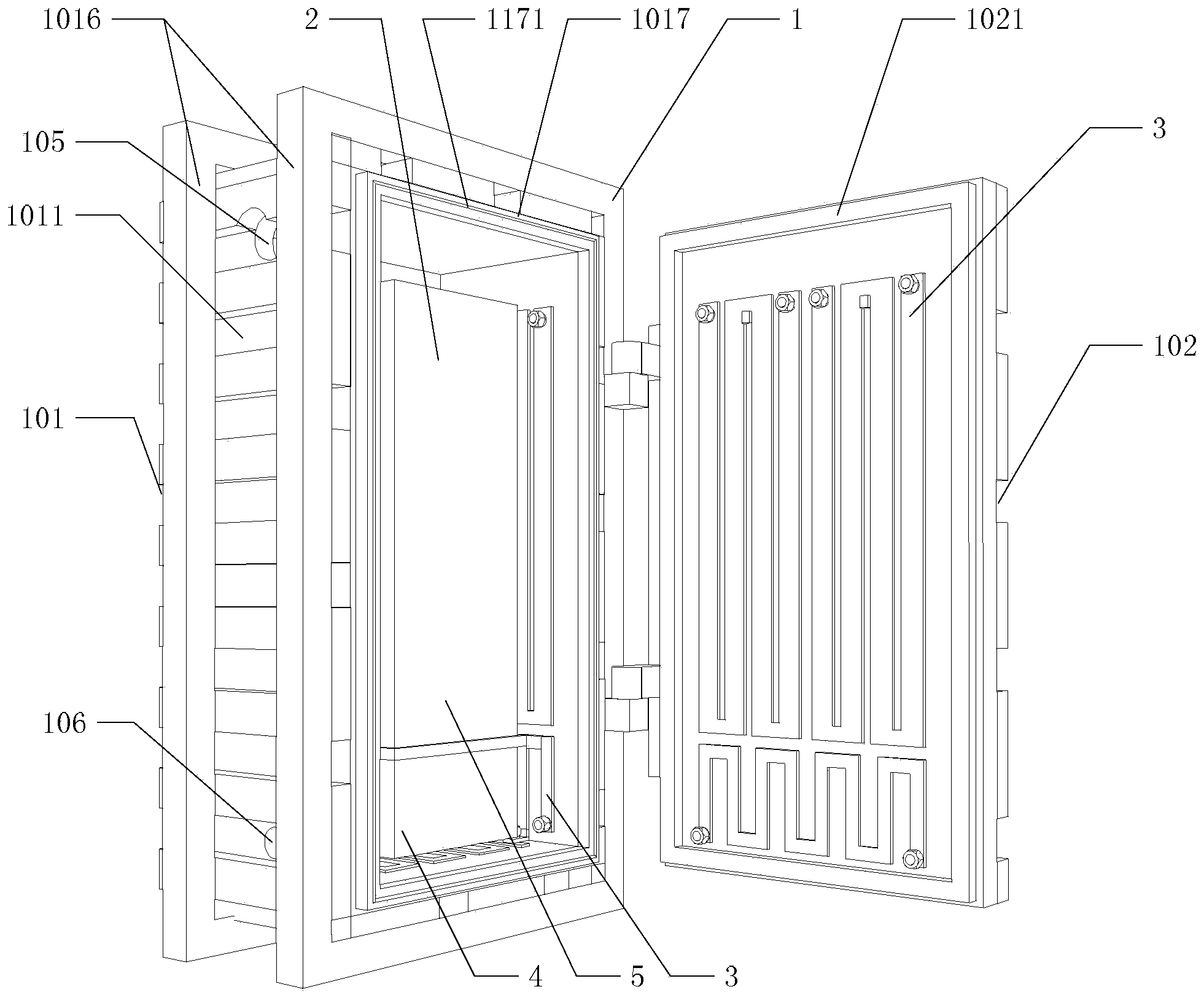

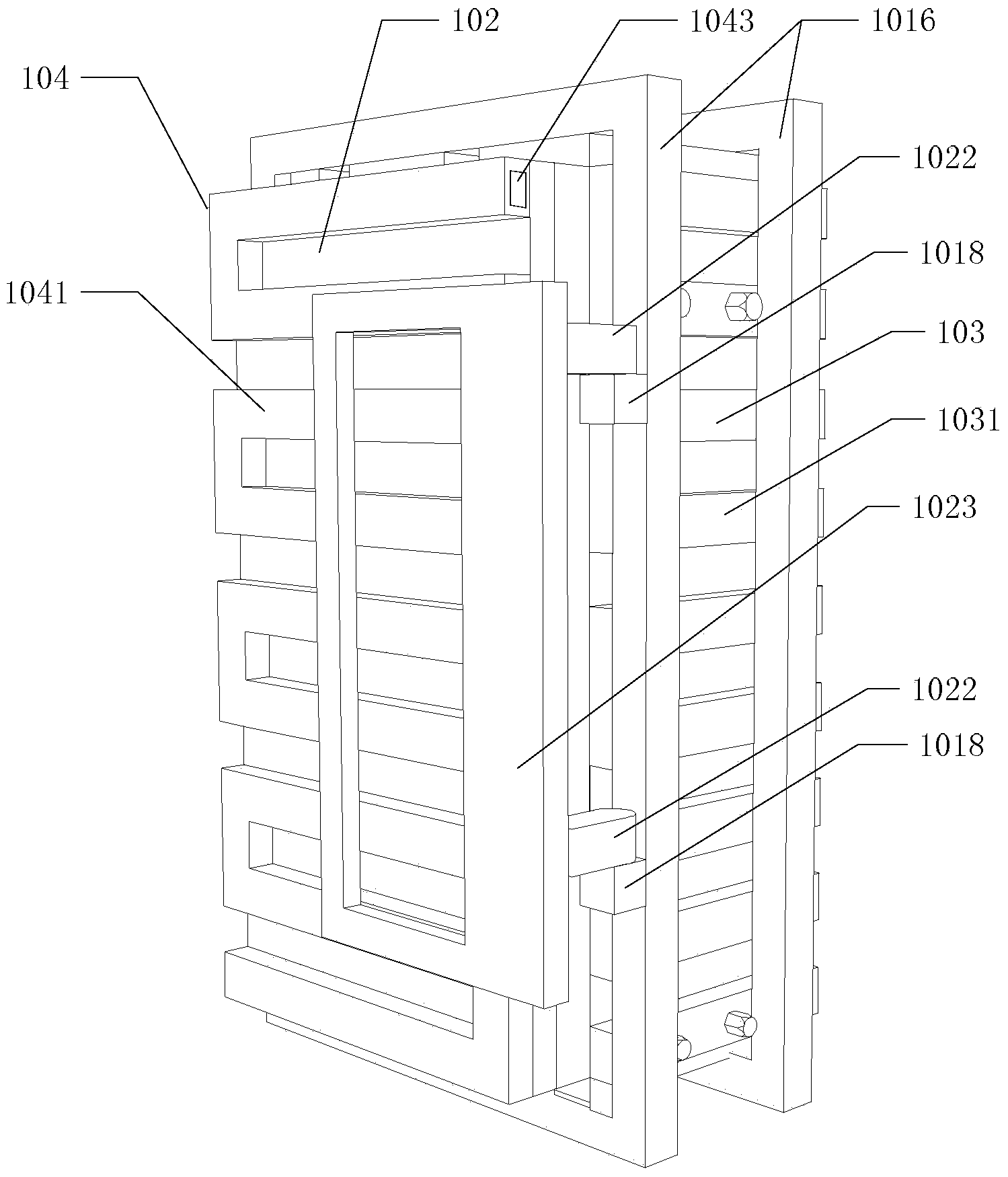

[0036] Such as figure 2As shown, the chemical vapor deposition equipment for preparing ultra-large bulk materials in the present invention includes a housing 1 , a reaction system 2 and a heating element 3 located between the housing and the reaction system. The inside of the housing 1 is provided with the reaction system 2, the reaction system 2 includes a raw material supply device 4 and a reaction chamber 5, the raw material supply device 4 is, for example, a zinc tank, which provides chemical For depositing required raw materials, the heating element 3 is provided on the inner wall of the casing 1 outside the raw material supply device 4 and the reaction chamber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com