Reaction kettle for making biologic diesel oil

A biodiesel and reactor technology, applied in the direction of biological raw materials, biofuels, petroleum industry, etc., can solve the problems of sufficient reaction of various materials, insufficient esterification reaction, and failure of materials to be combined, so as to reduce the solvent recovery process , alcoholysis and esterification reactions are sufficient, and the production efficiency is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

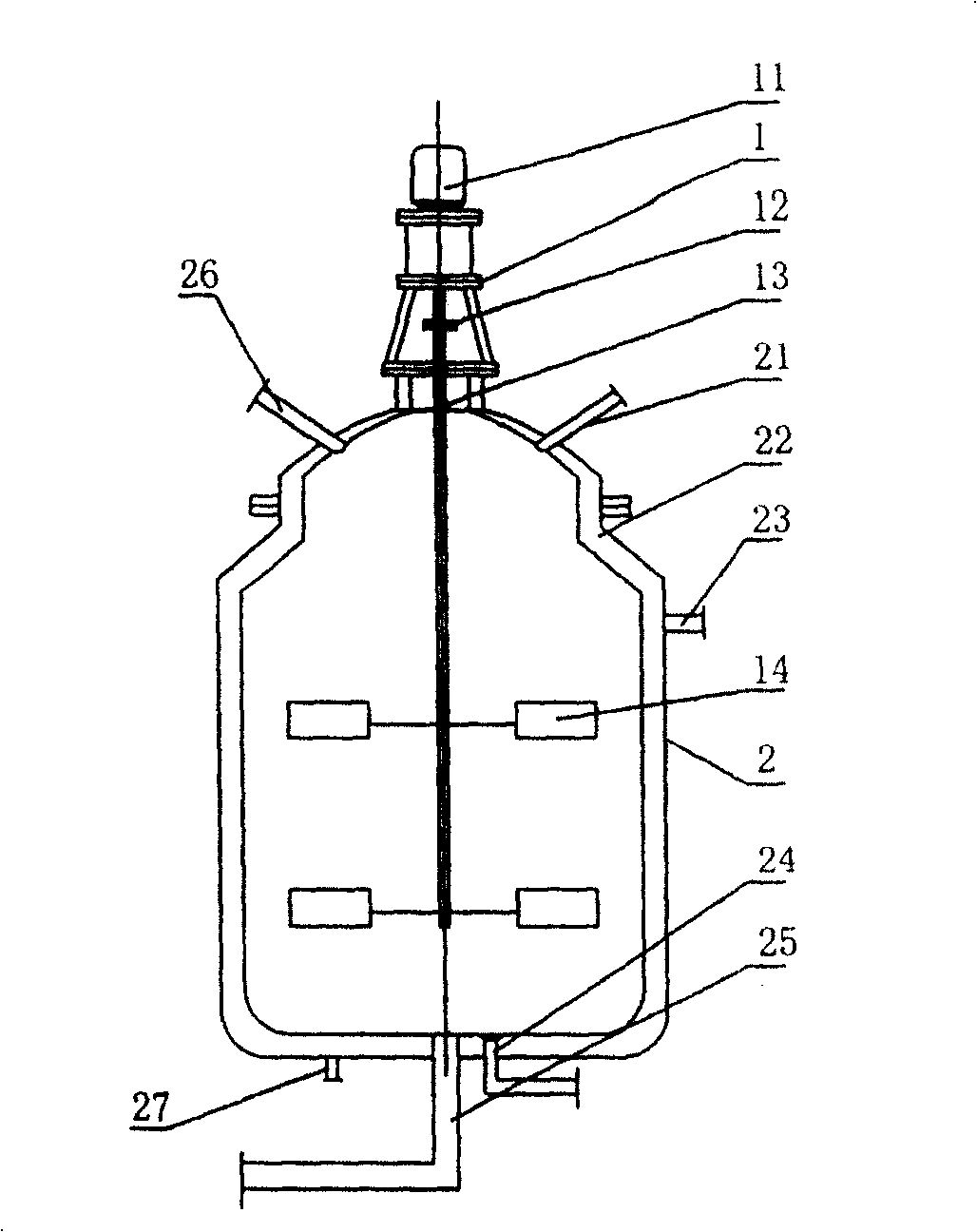

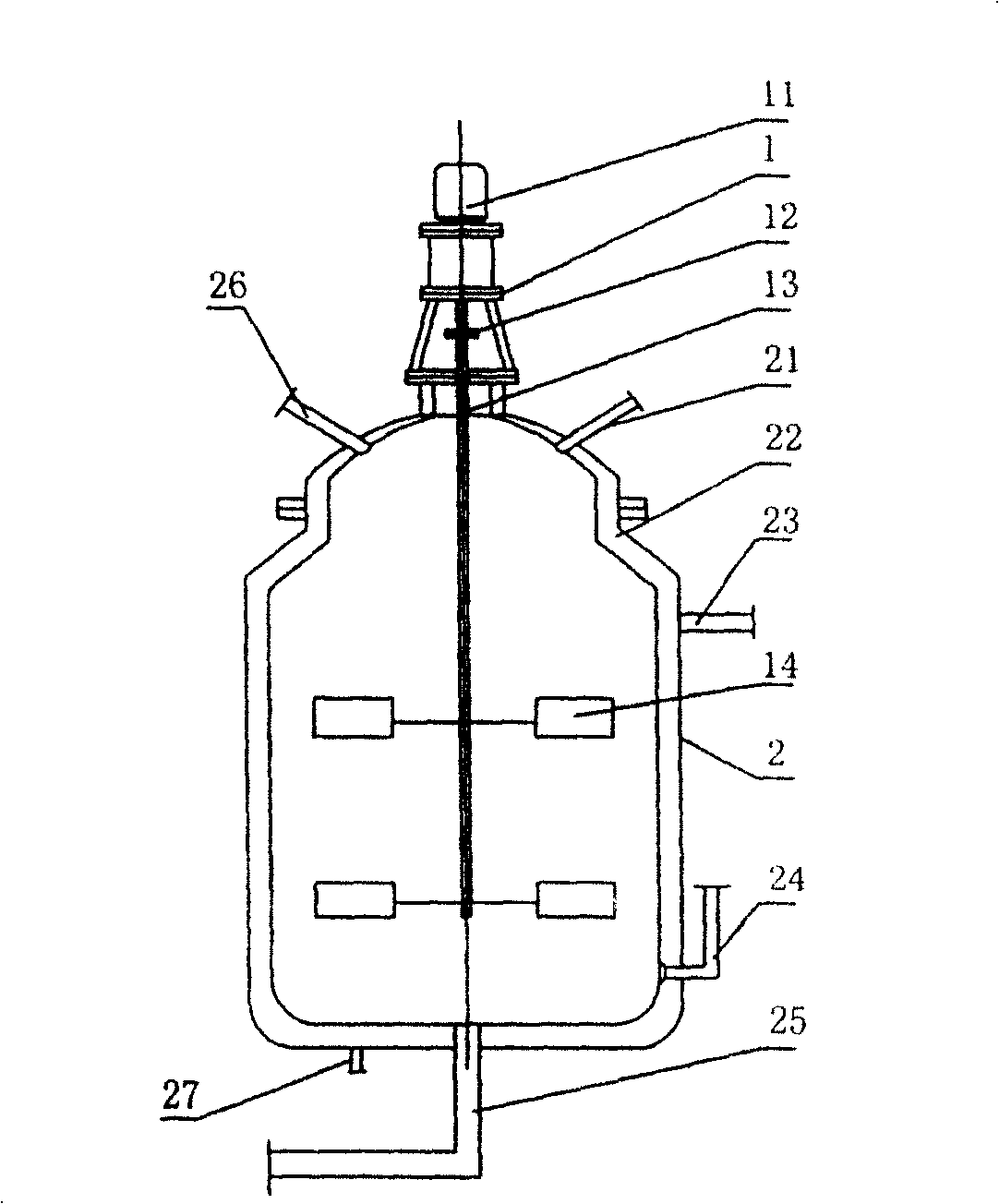

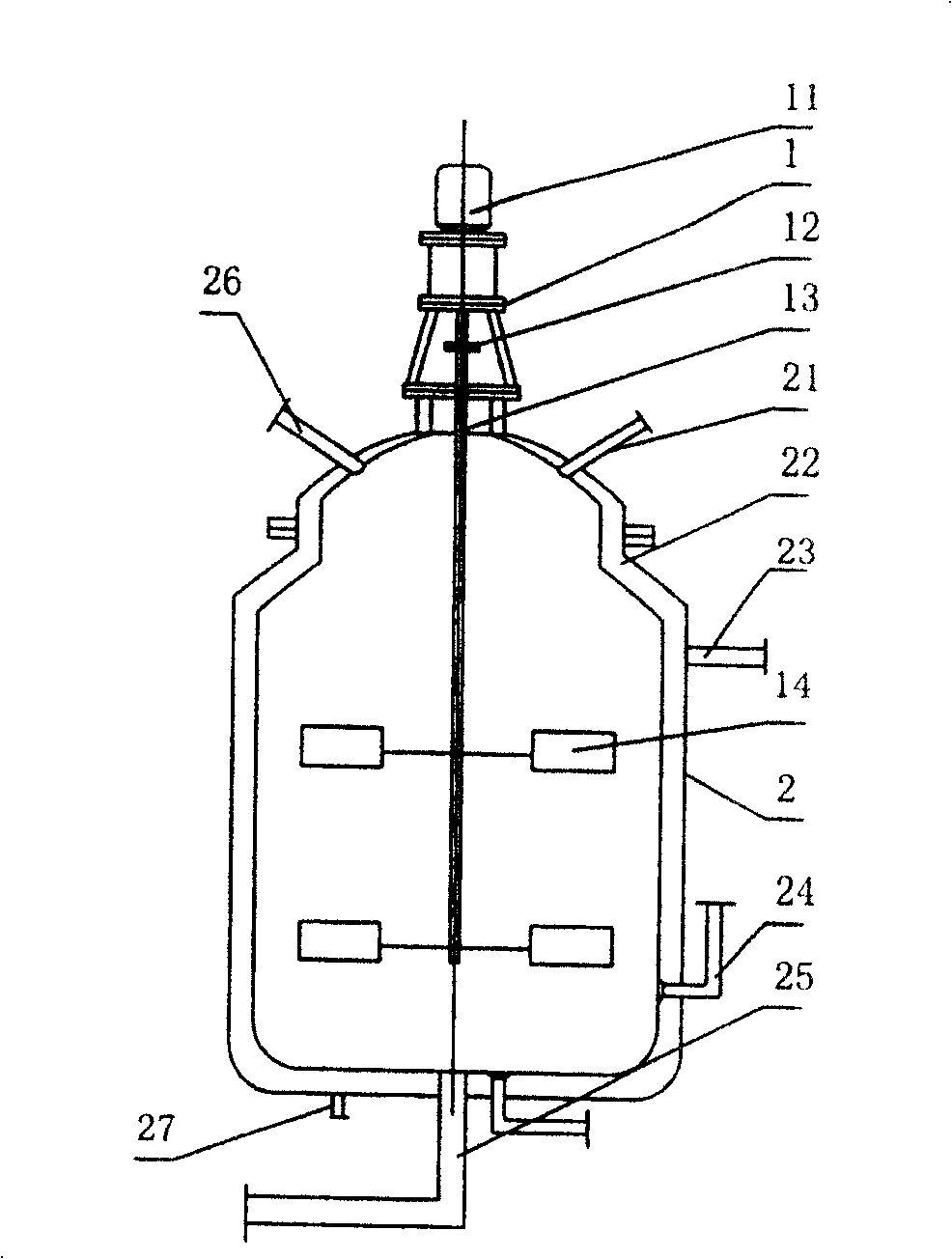

[0015] See figure 1 As shown, the reaction kettle for producing biodiesel of the present invention includes a kettle body 2 and a stirring device 1 installed on the kettle body 2. The stirring device 1 is composed of a motor 11, a shaft coupling 12, a stirring shaft 13 and blades 14. The motor 11 is fixed on the top of the kettle body 2, the output shaft of the motor 11 is connected with the stirring shaft through a coupling 12, and the lower part of the stirring shaft 13 is equipped with a blade 14, which stirs the materials in the reaction chamber to fully carry out the esterification reaction. See figure 1 As shown, the still body 2 of the present invention is a jacketed structure with an interlayer 22, the still body 2 is provided with a steam inlet 23 and a condensed water outlet 27, and the steam inlet 23 and the condensed water outlet 27 communicate with the interlayer 22, so that the steam Forced circulation in the interlayer 22 heats the material in the still body. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com