Compound enzyme preparation for preparing oyster peptide and application thereof

A technology for compounding enzymes and oyster peptides, applied in the fields of application, protein food ingredients, food science, etc., can solve the problems of large environmental pollution, heavy smell of small molecular peptides, limiting the application of functional factors, etc., and achieves good effect and molecular weight distribution. The effect of uniform, good application value and market potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

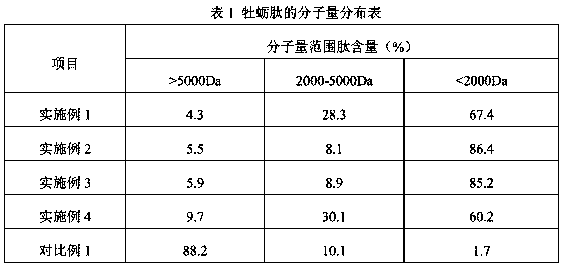

Examples

Embodiment 1

[0044] This example provides a compound enzyme preparation for preparing oyster peptides, including the following components: cellulase, mesophilic α-amylase, acid protease, neutral protease, alkaline protease, papain and flavor protease; Accounting for the mass percentage of oysters, the dosage of each component is: 0.4% cellulase, 0.3% medium temperature α-amylase, 0.15% acid protease, 0.5% neutral protease, 0.6% alkaline protease, papain 0.15%, flavor protease 0.3%.

[0045] The method for preparing the oyster peptide by using the above compound enzyme preparation comprises the following steps:

[0046] (a) After cleaning and draining the fresh oysters, beat them evenly with a beater, and prepare the oyster slurry to be enzymatically hydrolyzed with the evenly beaten oyster slurry and water at a mass ratio of 1:2;

[0047] (b) Weigh cellulase, medium temperature α-amylase, acid protease, neutral protease, alkaline protease, papain and flavor protease according to the ratio...

Embodiment 2

[0053] This example provides a compound enzyme preparation for preparing oyster peptides, including the following components: cellulase, mesophilic α-amylase, acid protease, and flavor protease; For: cellulase 0.4% ~ 0.6%, medium temperature α-amylase 0.3% ~ 0.5%, acid protease 0.2% ~ 0.3%, flavor protease 0.3% ~ 0.5%.

[0054] The method for preparing the oyster peptide by using the above compound enzyme preparation comprises the following steps:

[0055] (a) After cleaning and draining the fresh oysters, beat them evenly with a beater, and prepare the oyster slurry to be enzymatically hydrolyzed with the evenly beaten oyster slurry and water at a mass ratio of 1:2;

[0056] (b) Weigh cellulase, acid protease and flavor protease respectively according to the ratio;

[0057] (c) Put the oyster slurry in a stirrer at 50-55°C, adjust the pH to 3.5 first, add cellulase and acid protease to hydrolyze for 4 hours; cellulase can effectively act on the fiber layer of oysters in an a...

Embodiment 3

[0062] This example provides a compound enzyme preparation for preparing oyster peptides, including the following components: cellulase, mesophilic α-amylase, neutral protease and flavor protease; The dosages of the components are respectively: 0.2%-0.4% of cellulase, 0.1%-0.5% of medium-temperature alpha-amylase, 0.4%-0.6% of neutral protease, and 0.1%-0.5% of flavor protease.

[0063] The method for preparing the oyster peptide by using the above compound enzyme preparation comprises the following steps:

[0064] (a) After cleaning and draining the fresh oysters, beat them evenly with a beater, and prepare the oyster slurry to be enzymatically hydrolyzed with the evenly beaten oyster slurry and water at a mass ratio of 1:2;

[0065] (b) Weigh cellulase, medium temperature α-amylase, acid protease, neutral protease, alkaline protease, papain and flavor protease according to the ratio;

[0066] (c) Put the oyster slurry into a stirrer at 50-55°C, first adjust the pH to 3.5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com