Vacuum leak detection automatic system with adjustable sensitivity

A sensitivity and leak detection technology, which is applied in the field of vacuum leak detection automation system, can solve the problems that the vacuum leak detection system cannot perform leak detection, etc., and achieve the effect of improving test data processing capacity, increasing utilization rate, improving convenience and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

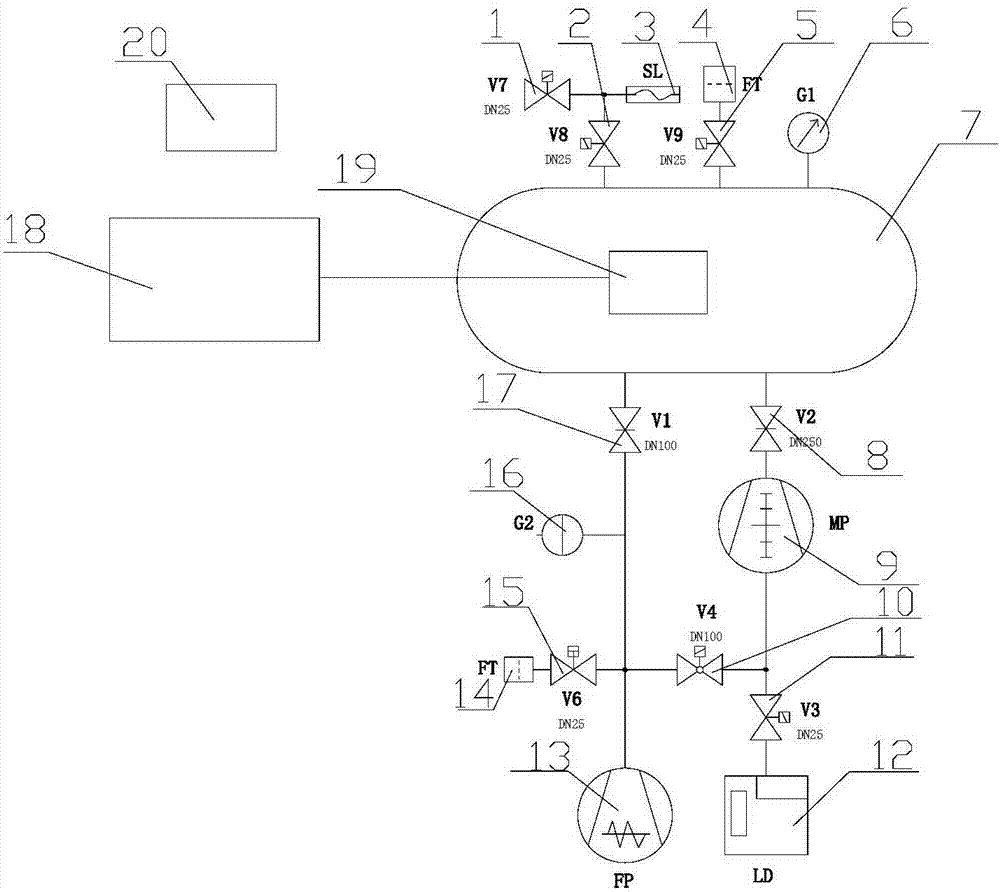

[0020] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] refer to figure 1 , the entire system of the present invention mainly includes a vacuum acquisition and measurement unit and a leak detection unit; the vacuum acquisition and measurement unit includes a vacuum chamber 7, a molecular pump 9, a screw pump 13, a vacuum gauge 6, pneumatic slide valves 8, 17, Controllable butterfly valve 10, solenoid valve and filter; the leak detection unit includes helium mass spectrometer leak detector 12, standard leak hole 3, inflation and deflation equipment 18 and computer control system 20, wherein, one end of the molecular pump 9 is passed through a pneumatic flashboard The valve one 18 is connected to the vacuum chamber 7, and the other end of the molecular pump 9 is communicated with the helium mass spectrometer leak detector 12 and the screw pump 13 through the solenoid valve one 11 and the controllable but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com