Method for calibrating helium mass spectrometer leak detector

A helium mass spectrometer leak detector and calibration coefficient technology, applied in the field of vacuum metrology, can solve the problems of inability to perform continuous calibration, long measurement time period, large measurement uncertainty, etc., and achieve simple and easy calibration process and short calibration time period. , the effect of improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

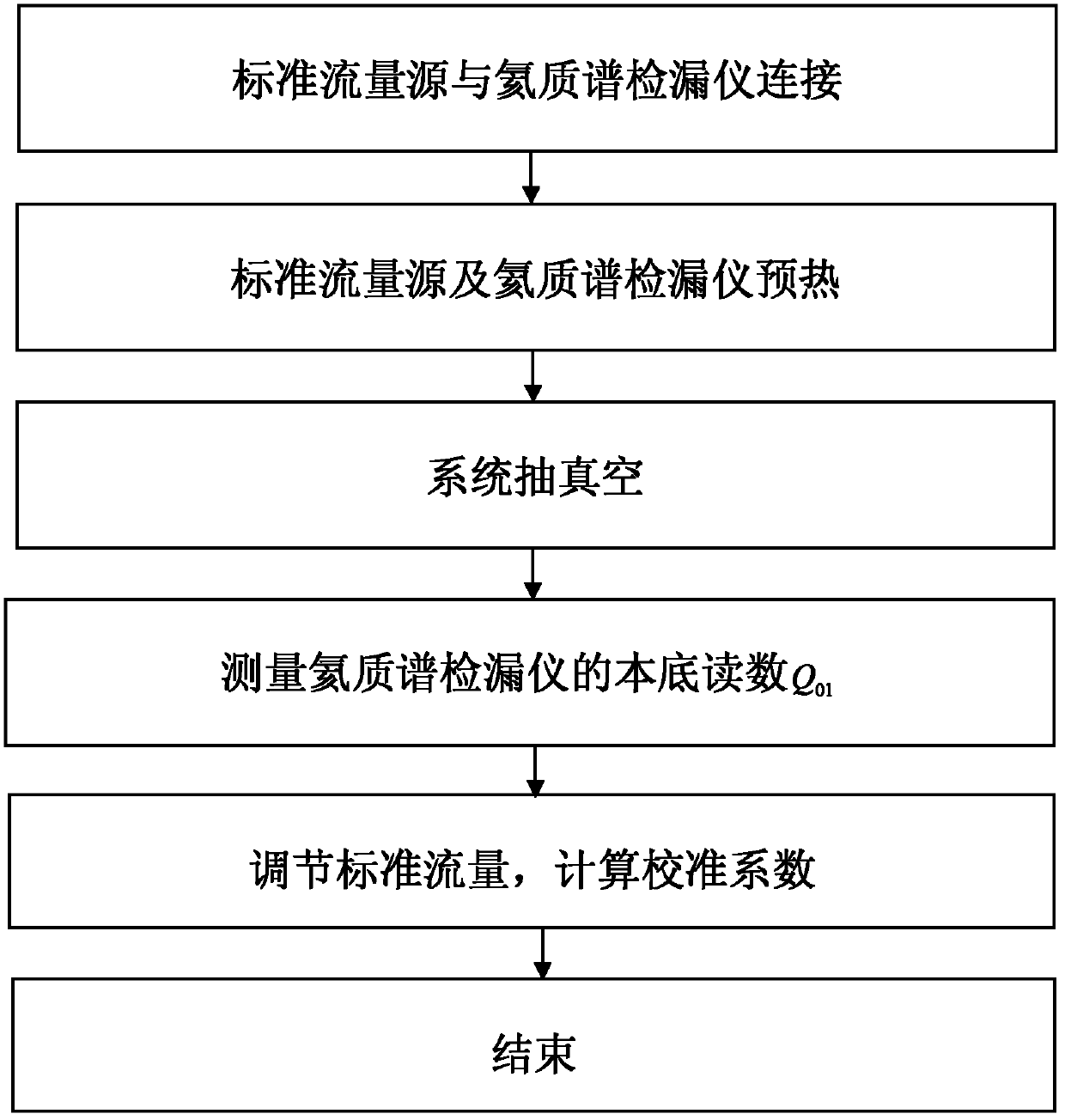

[0023] Such as figure 1 Shown, a method for calibrating a helium mass spectrometer leak detector, the method steps are as follows:

[0024] Step 1. Connect the standard flow source to the helium mass spectrometer leak detector, the standard flow source provides the standard flow, and the ambient temperature is kept at about 23°C;

[0025] Step 2. Preheat the standard flow source and the helium mass spectrometer leak detector. The preheating time is 4 hours;

[0026] Step 3, vacuumize the system;

[0027] Step 4. Measure the background reading Q of the helium mass spectrometer leak detector 01 , background reading Q 01 less than 5×10 -13 Pa·m 3 / s;

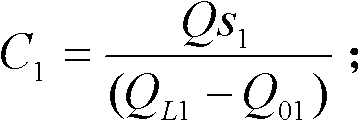

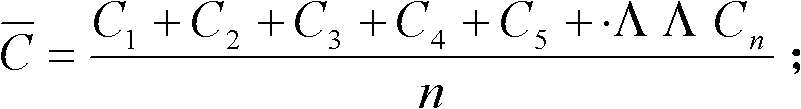

[0028] Step 5. Adjust the standard flow, the 2.35×10 provided by the standard flow source -10 Pa·m 3 / s standard flow Q s1 Introduced into the helium mass spectrometer leak detector to stabilize the standard flow Q s1 After that, when the indicated value no longer changes, read the indicated value Q of the helium mass spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com