Special worktable for laser tracker and laser tracking measurement method

A technology of laser tracker and workbench, which is applied to measuring devices, instruments, optical devices, etc., and can solve problems such as the inability to meet the measurement accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

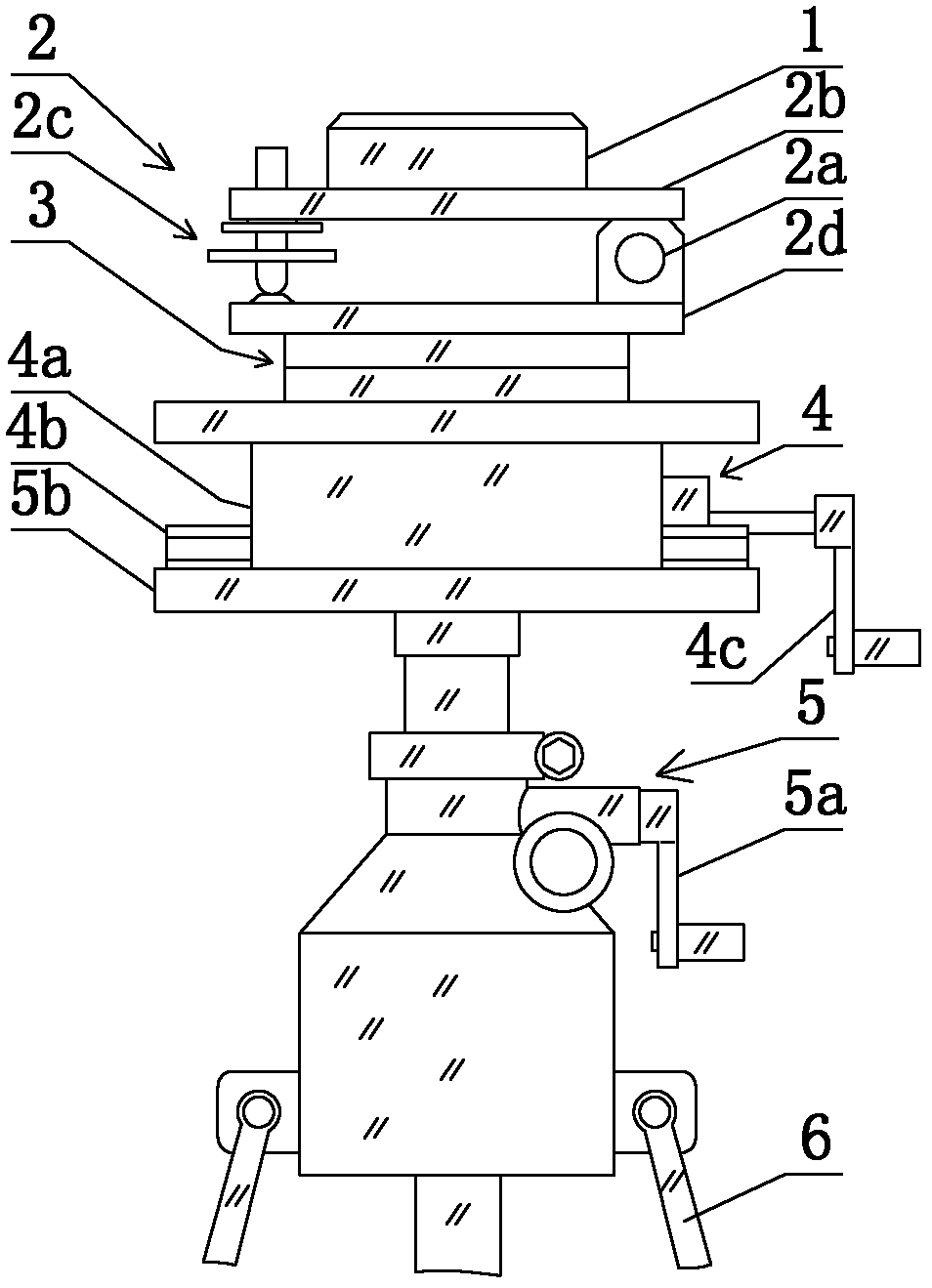

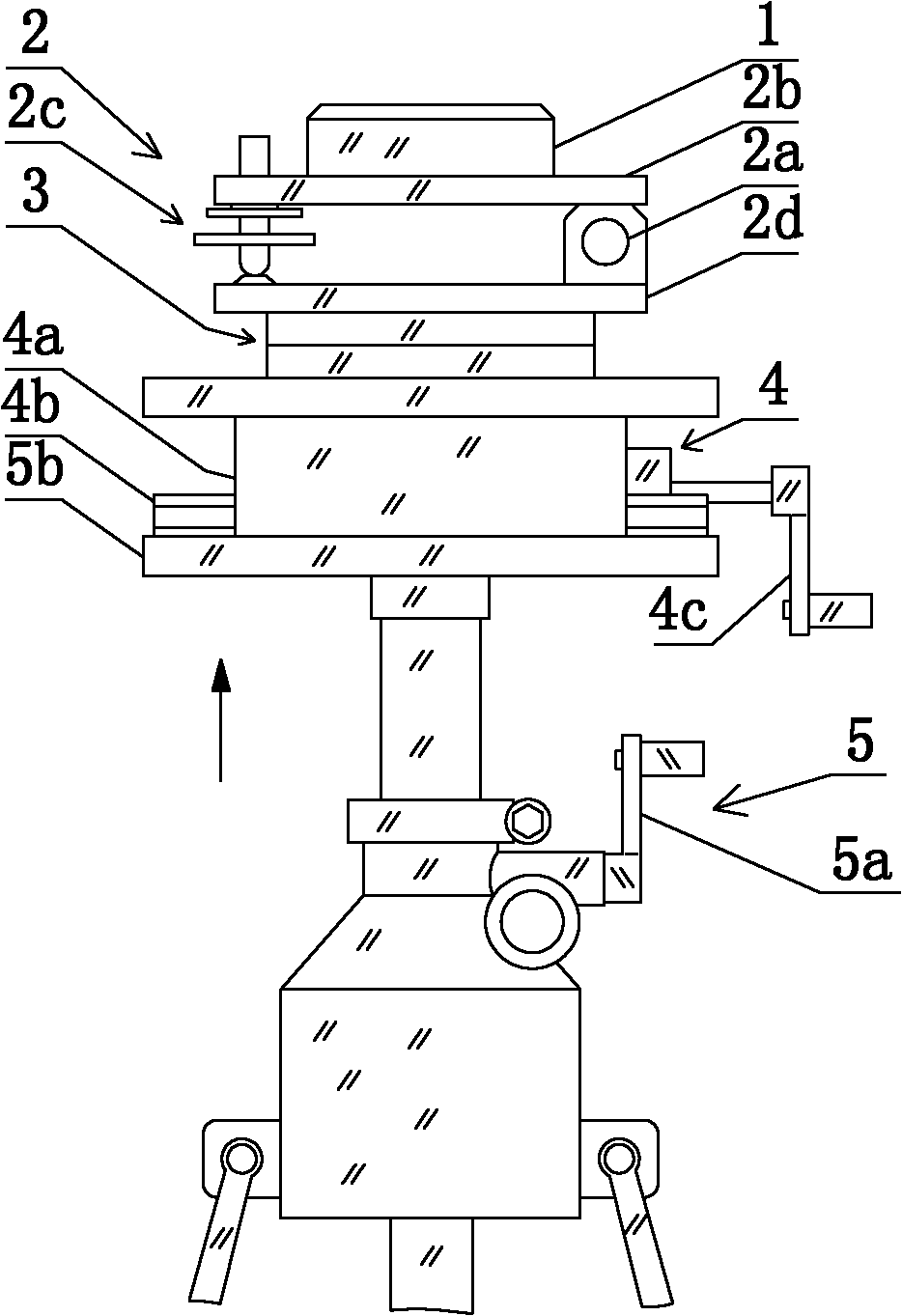

[0029] Such as Figure 2 to Figure 5 The special workbench for the laser tracker shown includes a mounting base 1 and a vertical angle adjustment device 2 , a horizontal angle adjustment device 3 , a horizontal translation adjustment device 4 and an up-and-down adjustment device 5 for adjusting the mounting base 1 . Wherein, the mounting seat 1, the vertical angle adjustment device 2, the horizontal angle adjustment device 3, the horizontal translation adjustment device 4 and the up and down lifting adjustment device 5 are arranged from top to bottom, and a bracket 6 is installed under the up and down lifting adjustment device 5, Used to support the entire dedicated workbench. The up and down lifting adjustment device 5 is used to drive the whole mechanism above it to move up and down, the horizontal translation adjustment device 4 is used to drive the whole mechanism above it to do horizontal translation movement, and the horizontal angle adjustment device 3 is used to drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com