Blow moulding shaping apparatus

A technology of blow molding and components, which is applied in the direction of household appliances, hollow objects, and other household appliances, etc. It can solve the problems of increasing the workload of forming operation managers, difficulty in finding the correct position of conveying parts, and misalignment of conveying parts, etc., to achieve Improved dimensional accuracy, easy positioning, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, embodiments to which the method and apparatus of the present invention are applied will be specifically described with reference to the drawings.

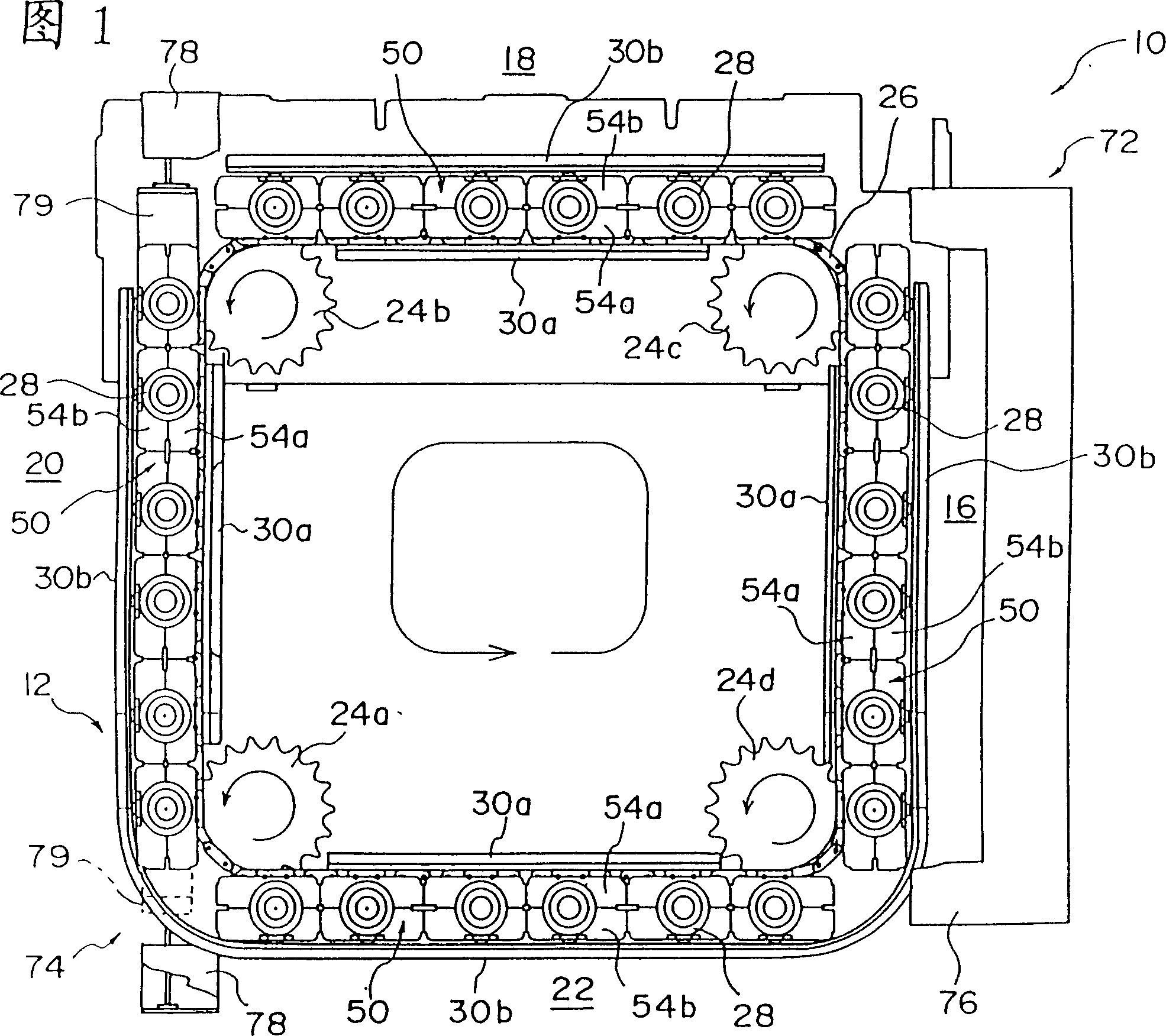

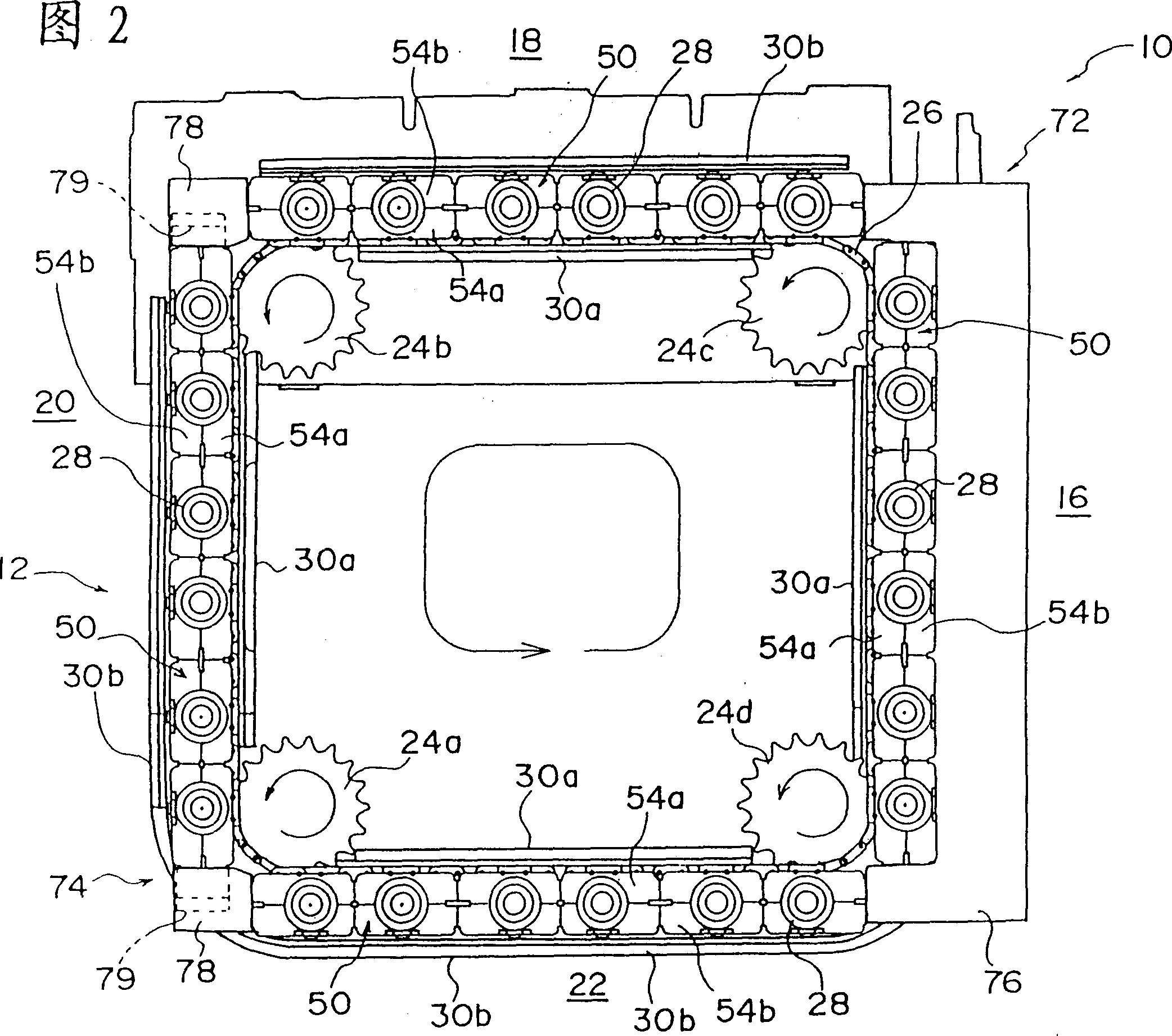

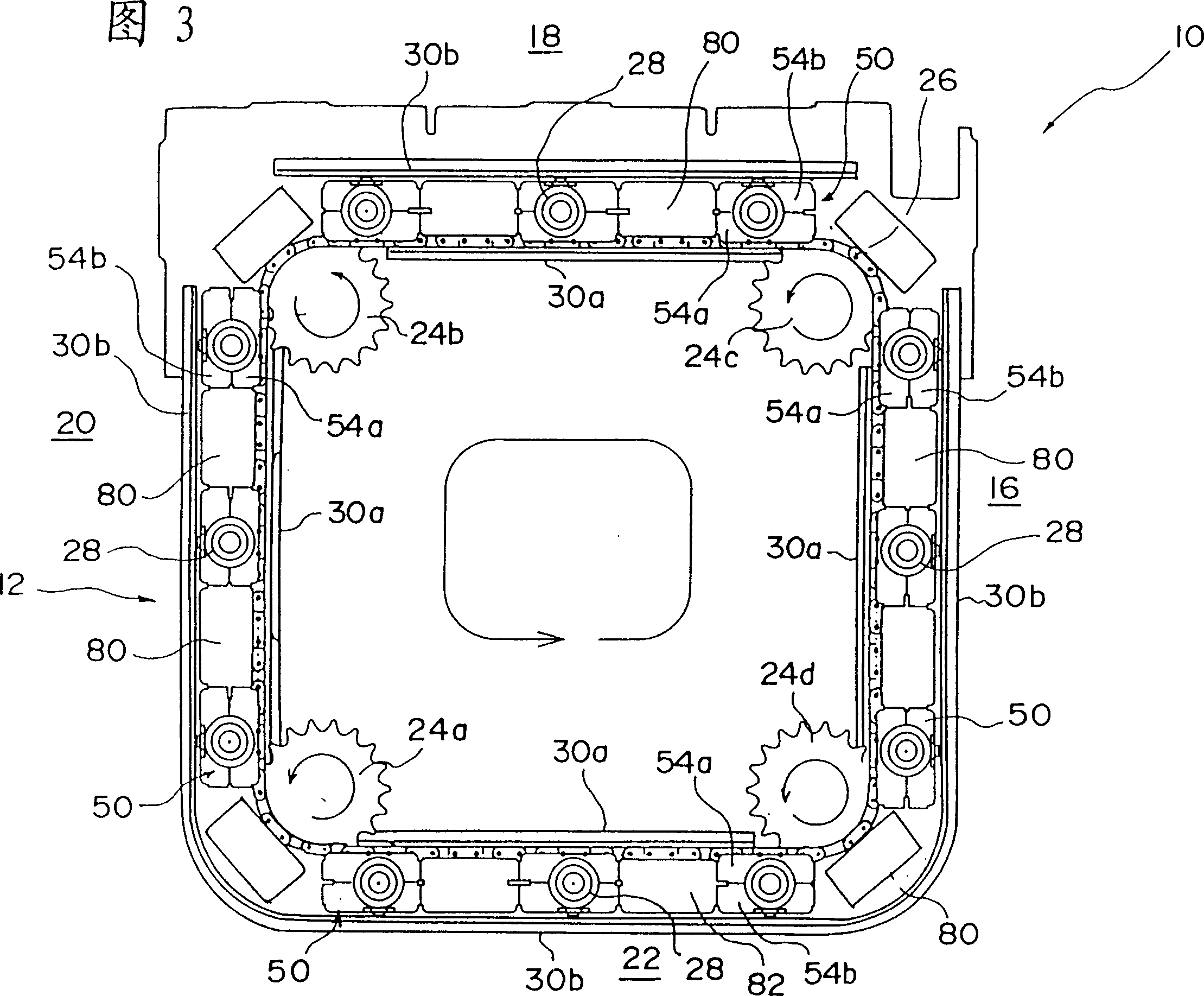

[0047] 1 and 2 are diagrams showing a blow molding apparatus according to an embodiment of the present invention. The details of each operation unit are omitted here because they have already been shown in Japanese Patent Laid-Open No. 8-132517 and No. 8-224775 related to the applicant's application.

[0048] The blow molding device 10 is provided with a substantially square conveyance path 12 , and four linear portions of the conveyance path 12 are respectively used as working sections.

[0049] And, on the 4 linear parts as these working sections, respectively are arranged: the receiving part 16 that is used to receive the preform 14 (referring to Fig. 5); The heating part 18 suitable for the temperature of blow molding; the blow molding part 20 that blows molds the preform 14 heated in the heating part 18 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com