Connecting mechanism convenient to assemble

A connecting mechanism and rotating connection technology, which is applied in the direction of connecting components, mechanical equipment, etc., can solve the problems of heavy workload, easy slippage of bolts, and easy existing problems, so as to ensure smoothness, avoid screw failure, and prevent buckle components from being lost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

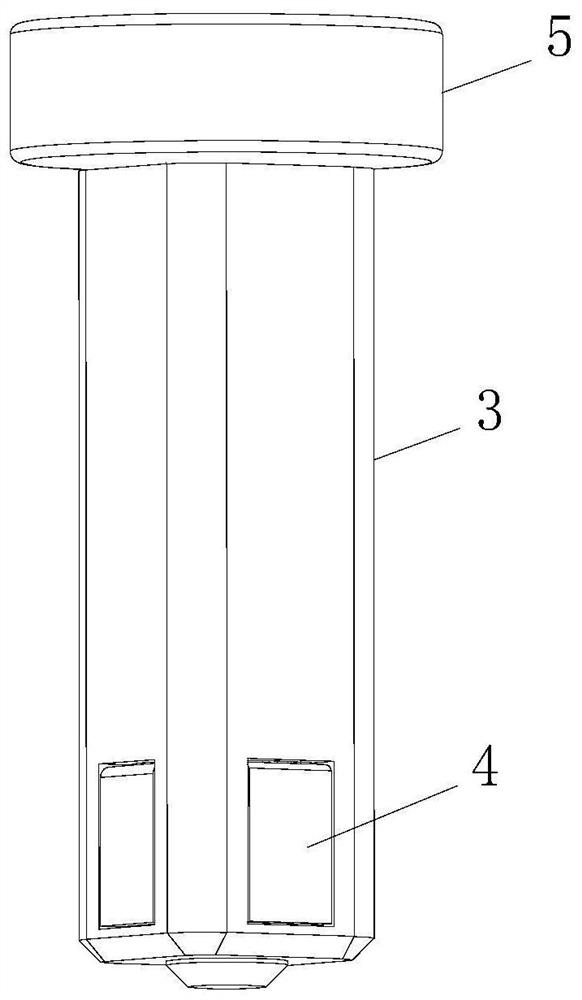

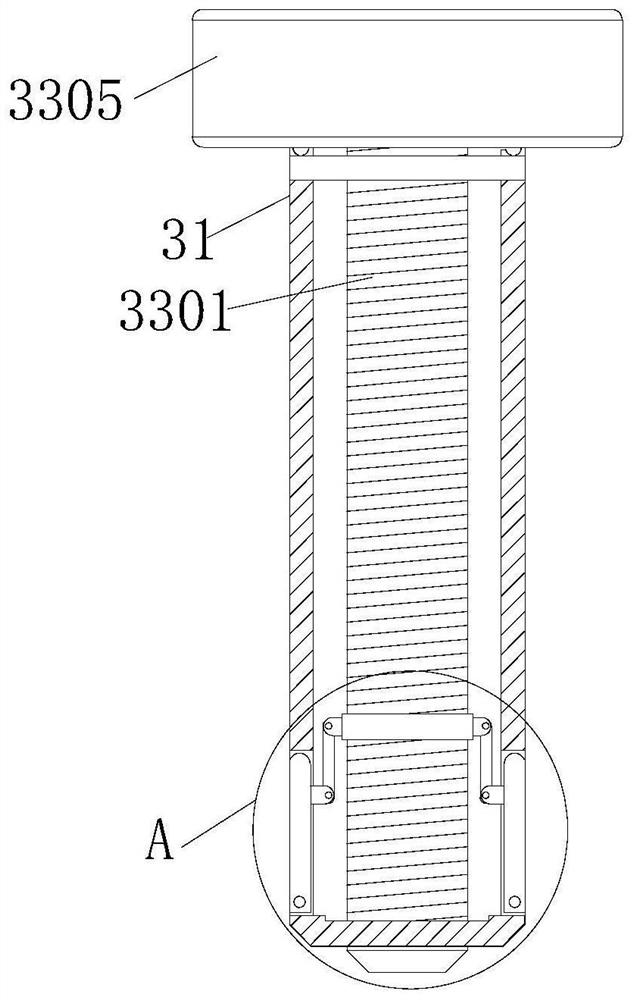

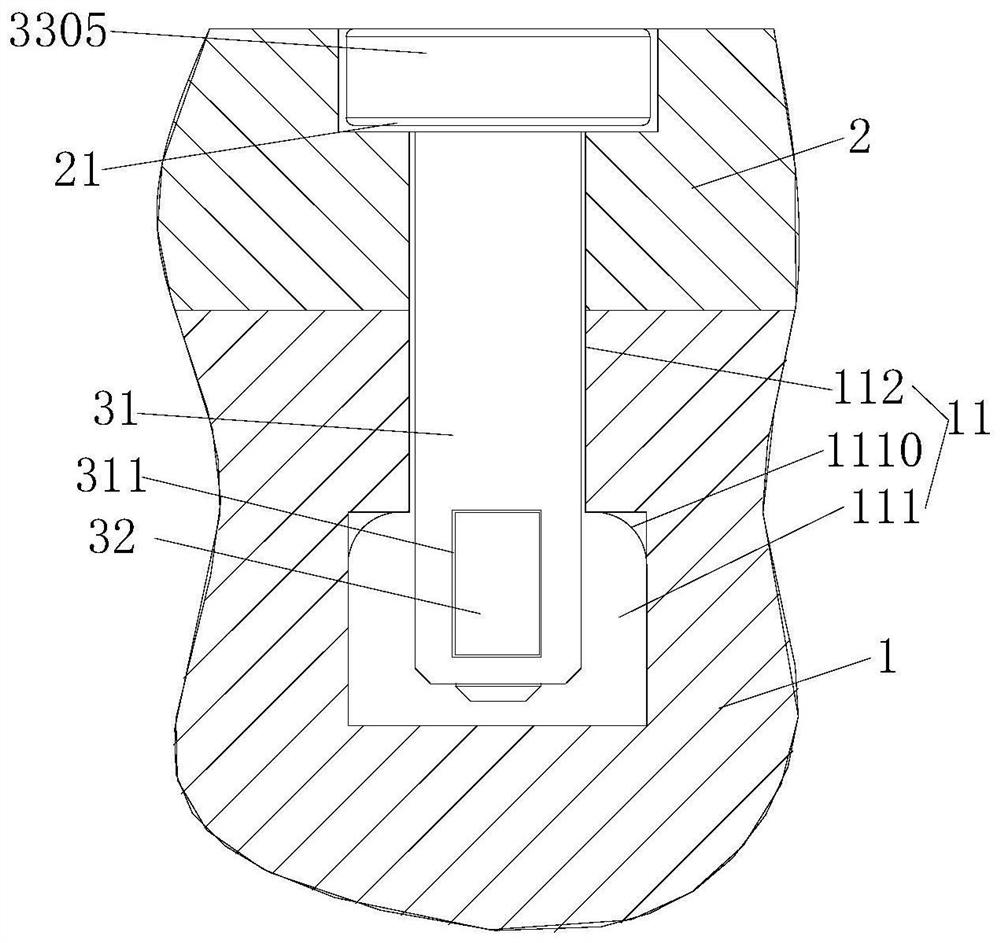

[0037] Such as Figure 1-Figure 8 As shown, a connection mechanism for easy assembly, including the first part 1 and the second part 2 to be connected;

[0038] The first part 1 includes a first groove 11, the first groove 11 is narrow on the outside and wide on the inside; the second part 2 is provided with a buckle assembly that can go deep into the first groove 11;

[0039] The buckle assembly includes a sleeve 31 and a force applying unit 33. At least one functional hole 311 is opened on the side wall of the sleeve 31, and each functional hole 311 is provided with a deflection buckle 32. The deflection buckle The lower end of the plate 32 is hinged with the sleeve 31, and the force applying unit 33 drives the upper end of the deflection pinch plate 32 to be replaced between two stations. The first station is located in the functional hole 311, and the second station is located in the sleeve. The outside of the cylinder 31 can make the buckle part be locked in the first gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com