Four-target ball combined measurement device and method for industrial robot posture

A technology for industrial robots and measuring devices, applied in measuring devices, using optical devices, radio wave measuring systems, etc., can solve the problems of reducing the accuracy of the measuring system, time-consuming, and high requirements for synergy, and achieve the effect of low measurement uncertainty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A four-target ball combination measuring device for the pose of an industrial robot, comprising the following:

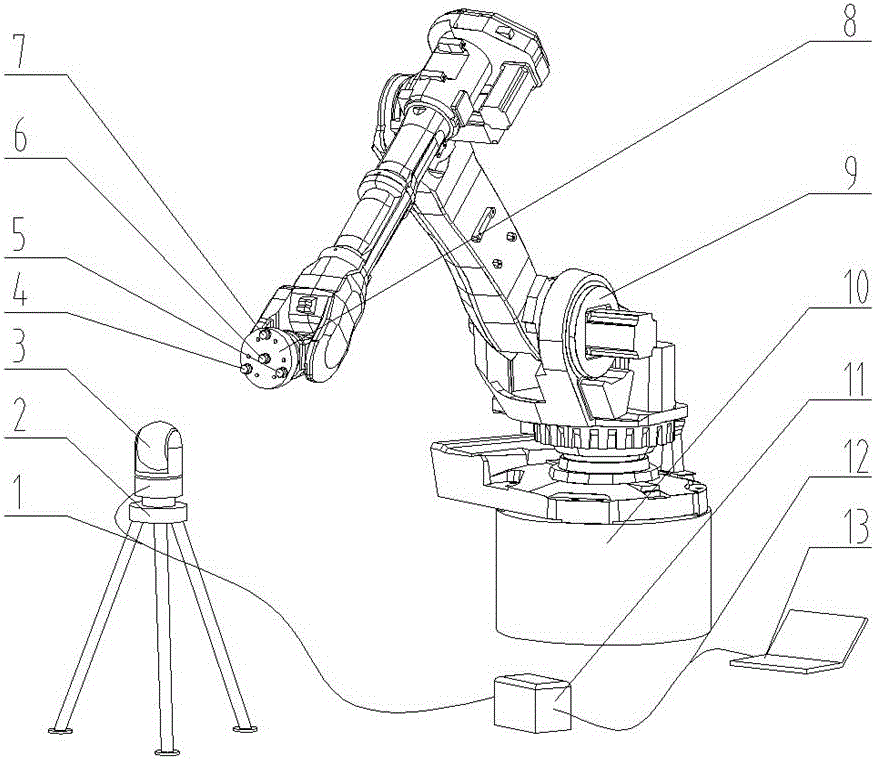

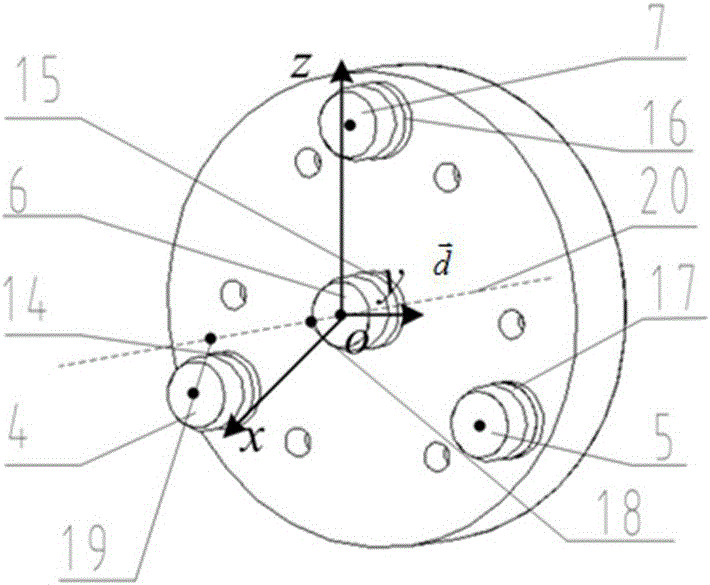

[0059] Such as figure 1 and figure 2 As shown, the four-target ball combination measuring device of the industrial robot pose of the present invention includes a laser tracker and a controller connecting cable 1, a laser tracker tripod 2, a laser tracker 3, a counterweight 8, and a laser tracker controller 11. Four-target ball measuring device; the laser tracker 3 is fixedly supported by the laser tracker tripod 2; the laser tracker controller 11 is connected to the laser tracker 3 through the laser tracker and controller connecting cable 1 Described computer 13 is connected with laser tracker controller 11 by controller and computer connection cable 12; Described counterweight 8 is a cylinder, and counterweight 8 is fixedly connected with the machine interface of industrial robot 9 to be tested, Provide the required rated load for the position and posture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com