Nickel-cadmium battery helium mass spectrometer leak rate test method

A test method, the technology of helium mass spectrometry, is applied in the field of helium mass spectrometry leak rate testing of nickel-cadmium batteries, which can solve the problems of inability to quantify the overall sealing performance of the battery, lack of data support, and low test accuracy, and achieve convenient testing, accurate data, and high testing level. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

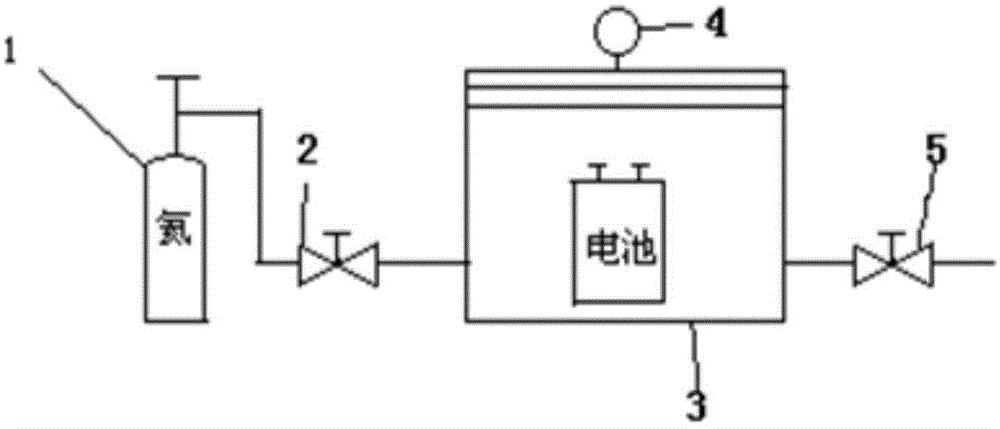

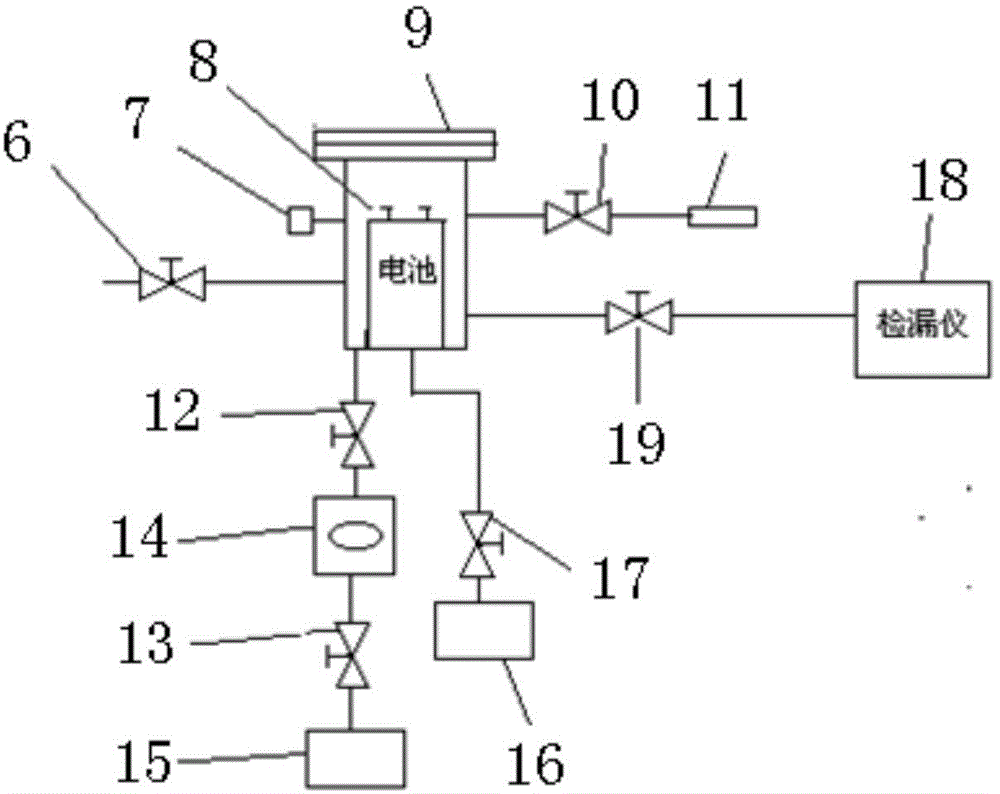

[0017] See attached figure 1 and figure 2 .

[0018] A method for testing the helium mass spectrometry leak rate of a nickel-cadmium battery: a helium mass spectrometry leak rate test is introduced into the sealing performance inspection of a nickel-cadmium single battery, and after the single battery is sealed, the single battery that has passed the chemical leak detection is placed in a sealed Fill the tank with helium at a specified pressure, take it out after a specified time at constant pressure, use nitrogen to spray the battery surface and welds, and then put it into the detection chamber of the system. When the vacuum degree of the detection chamber reaches the specified requirements, Open the detection valve, and use the helium mass spectrometer leak detector to quantitatively detect the overall leak rate of the nickel-cadmium single battery. Through this method, it is detected that the gas leakage rate level of the single battery is better than 1.0×10 -7 Pa·m 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com