High speed suction gun leak detection device and detection method for large transformer sealing element

A leak detection device and sealing element technology, which is applied in the field of leak detection and can solve the problems of prolonged detection time, long reaction time, and large flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

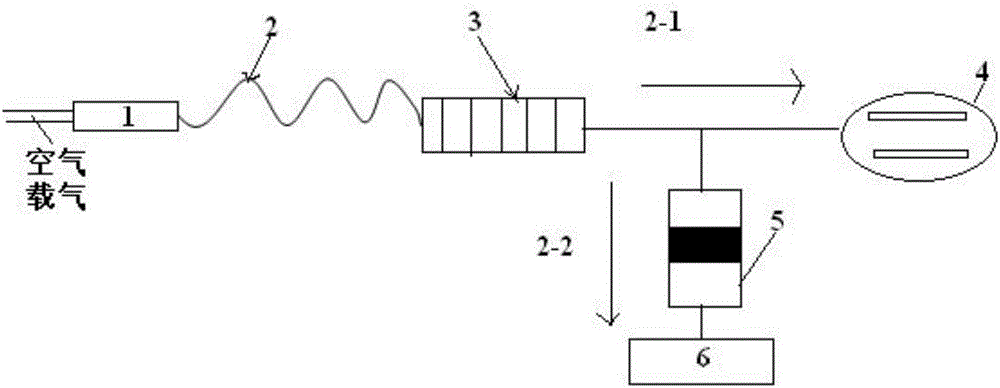

[0029] See attached figure 1 , a high-speed sniffing gun leak detection device for large-scale transformer sealing components, comprising: a high-speed sniffing gun 1, a sampling pipeline 2, a filter 3, a high-power suction pump 4, a helium separator 5 and a helium mass spectrometer 6, wherein, The air-carrier gas enters from the probe of the high-speed suction gun 1, passes through the first branch 2-1 of the sampling pipeline 2, and is extracted by the high-power suction pump 4, and the helium gas leaked from the leakage hole of the large-scale transformer sealing component to be detected enters After the probe of the high-speed suction gun 1, along with the high-speed air carrier gas provided by the high-power suction pump 4, it passes through the second branch 2-2 of the sampling pipeline 2, passes through the helium separator 5 and enters the mass spectrometry chamber of the helium mass spectrometer 6 (not shown in the figure) to analyze, and finally give the response lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com