Method for detecting leak of lithium ion storage battery before liquid injection and sealing

A battery, lithium ion technology, applied in the direction of detecting the appearance of fluid at the leakage point, using liquid/vacuum for liquid tightness measurement, etc., can solve the problems of waste, unable to judge the specific part of the battery leakage, etc., to reduce waste. , the effect of improving reliability and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

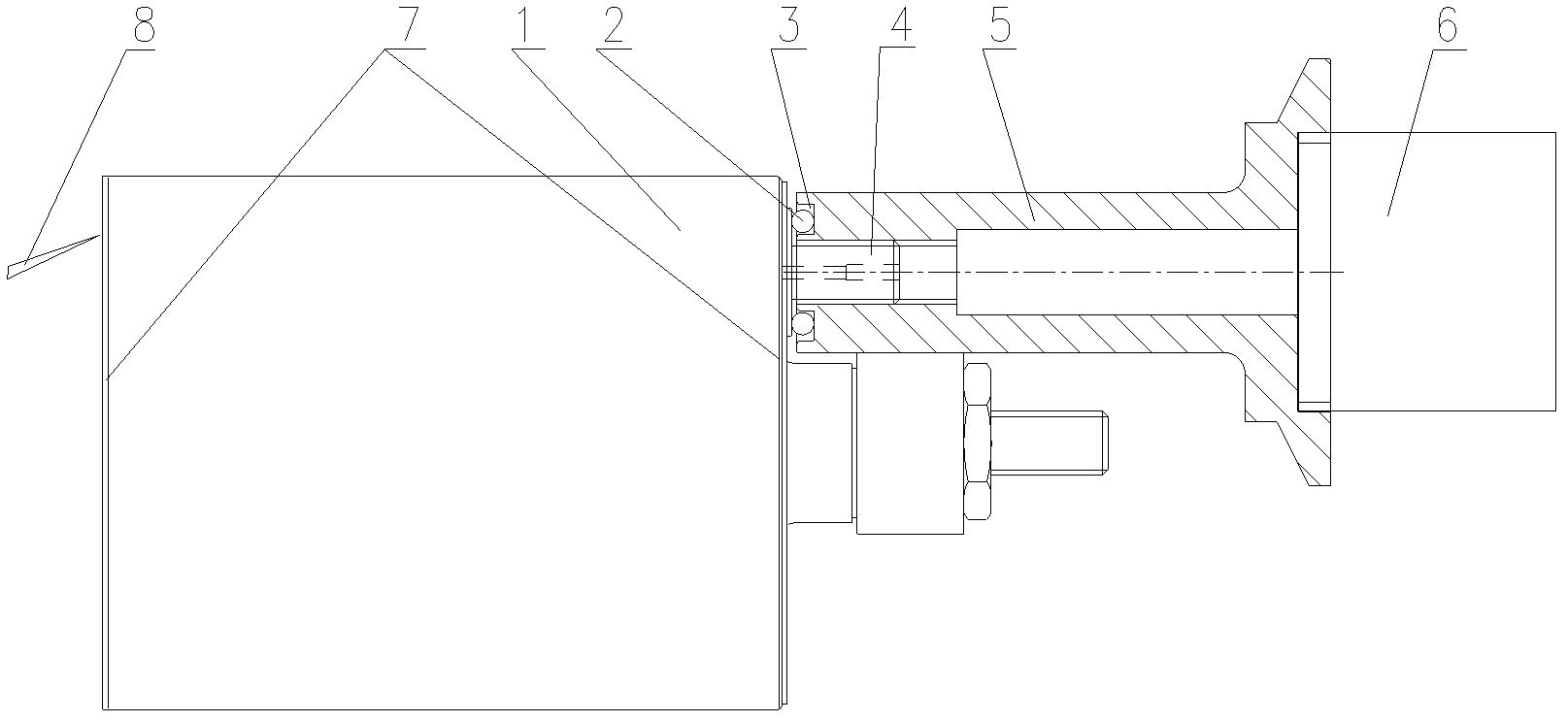

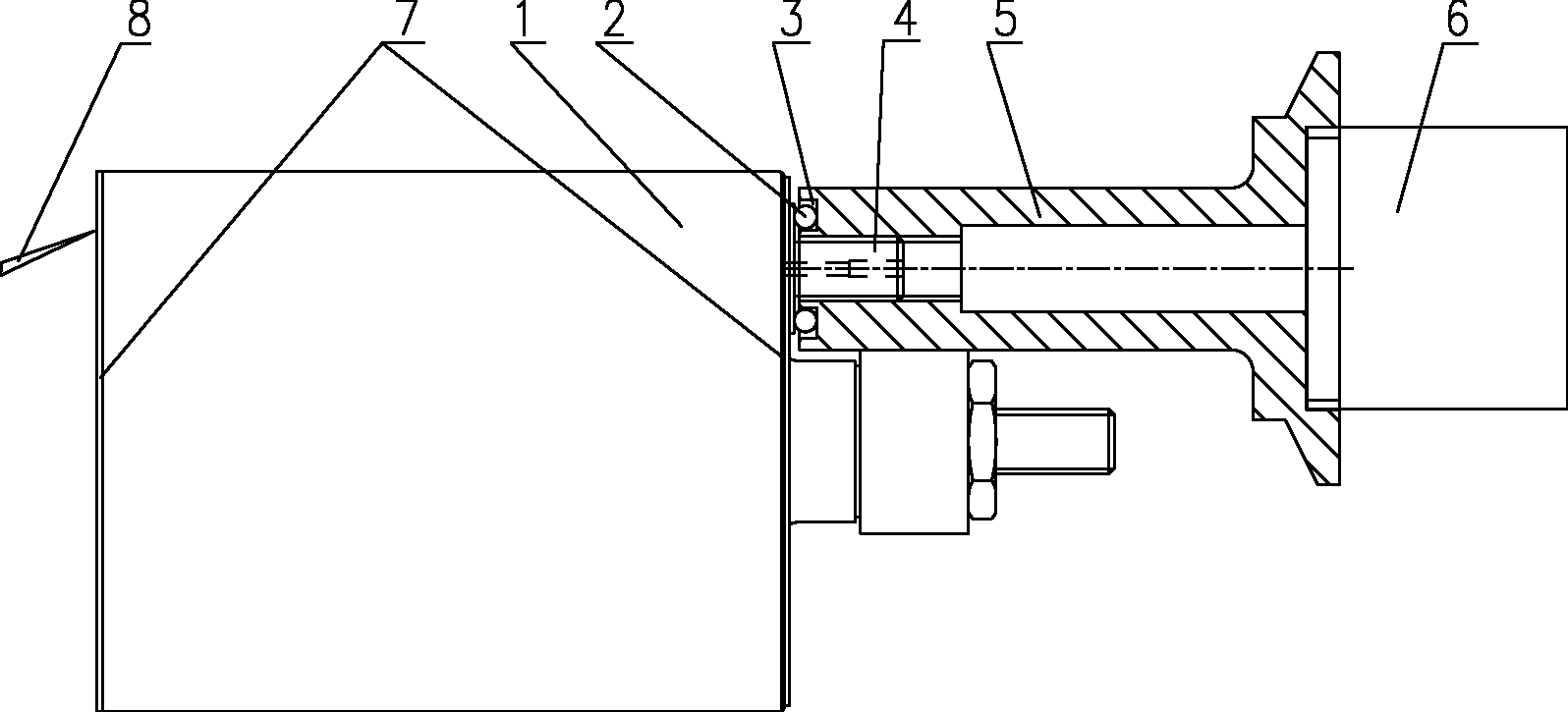

[0018] Refer to attached figure 1 , the working process of the present invention:

[0019] A method for leak detection before liquid injection and sealing of a lithium-ion storage battery, comprising the following steps:

[0020] (1) Connect one end of the connection chamber 5 to the quick-lock flange of the helium mass spectrometer leak detector 6;

[0021] (2) After placing the sealing ring 2 in the groove 3 on the end surface of the other end of the connection cavity, it is sealed and connected to the liquid injection port 4 of the battery before liquid injection and sealing. The helium mass spectrometer leak detector vacuumizes the inside of the battery through the liquid injection port of the battery. Carry out battery leakage detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com