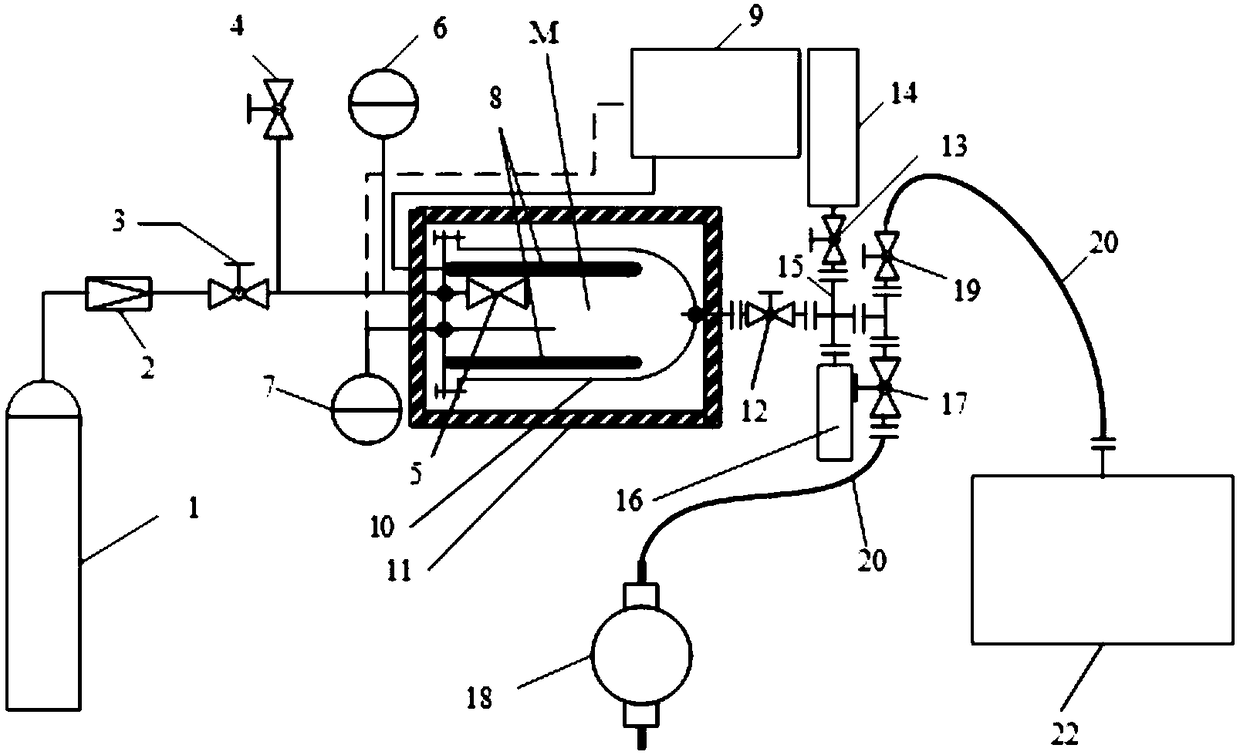

High-temperature and high-pressure helium leak quantitative detecting device and high-temperature and high-pressure helium leak quantitative detecting method

A quantitative detection, helium technology, applied in the detection field, can solve problems such as unsatisfactory needs, and achieve the effect of ingenious design and simple detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

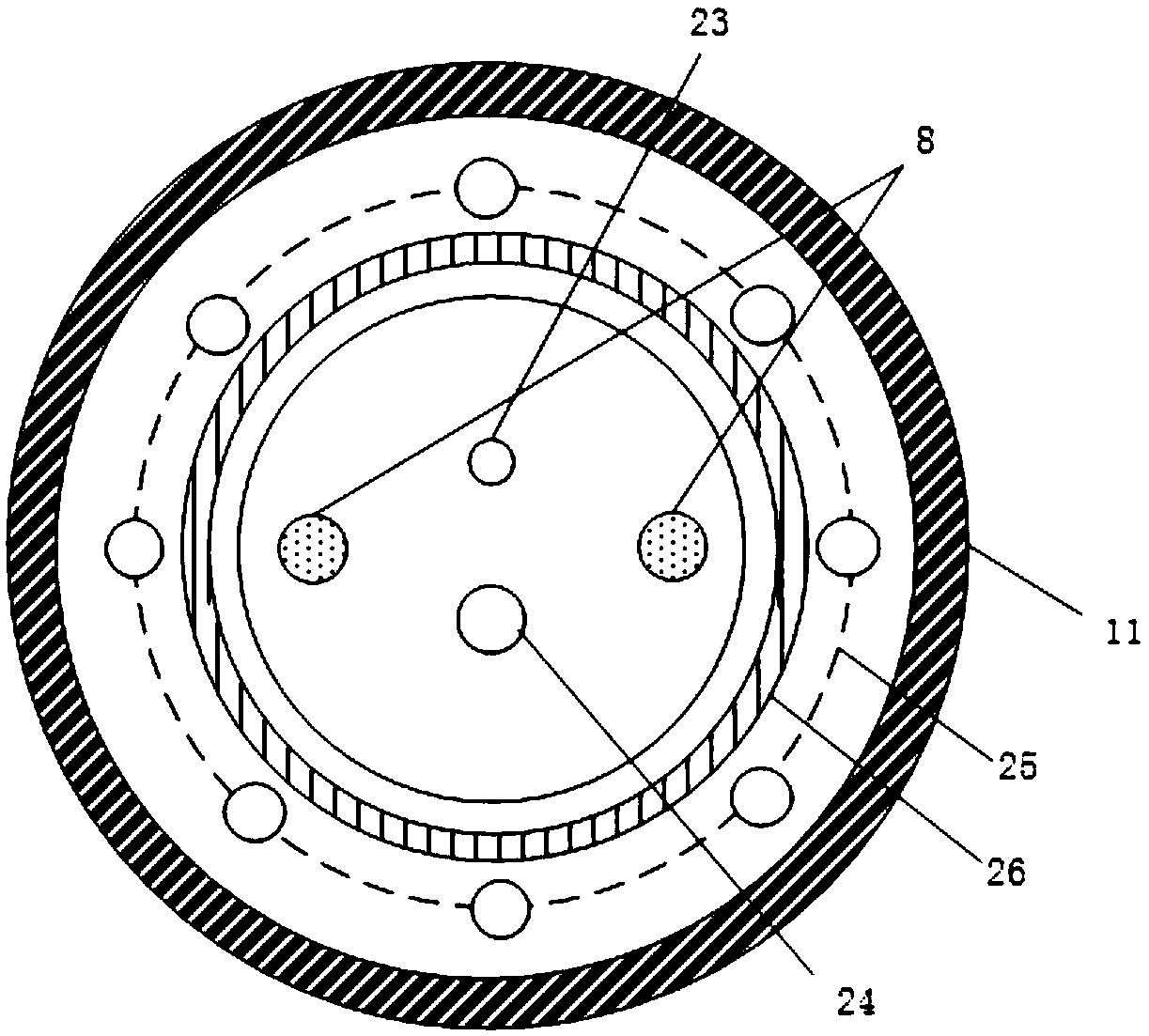

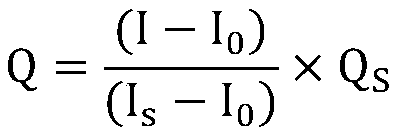

Method used

Image

Examples

Embodiment 1

[0054] Apply the above-mentioned helium leakage quantitative detection device and follow the above-mentioned steps to detect the helium leakage rate of the sealing equipment to be inspected--the double ferrule sealing structure equipment under the conditions of room temperature-250℃ and pressure 0-7MPa, and the inspection results as follows:

[0055] At room temperature and 0MPa, the leakage rate: 9.8×10 -7 Pam 3 / s;

[0056] At room temperature and 1MPa, the leakage rate: 9.5×10 -7 Pam 3 / s;

[0057] At room temperature and 7MPa, the leakage rate: 1.3×10 -6 Pam 3 / s;

[0058] At 150°C and 7MPa, the leakage rate: 1.6×10 -6 Pam 3 / s;

[0059] At 250°C and 7MPa, the leakage rate: 3.2×10 -6 Pam 3 / s.

Embodiment 2

[0061] Use the above-mentioned helium gas leakage quantitative detection device and follow the above steps to detect the helium gas leakage rate of the sealed equipment to be inspected--metal gasket sealed structure equipment under the conditions of room temperature -100°C and pressure 0-15MPa, and the test results as follows:

[0062] At room temperature and 0MPa, the leakage rate: 2.7×10 -9 Pam 3 / s;

[0063] At room temperature and 7MPa, the leakage rate: 6.1×10 -8 Pam 3 / s;

[0064] At room temperature and 15MPa, the leakage rate: 2.3×10 -7 Pam 3 / s;

[0065] At 100°C and 0MPa, the leakage rate: 2.7×10 -9 Pam 3 / s;

[0066] At 100°C and 7MPa, the leakage rate: 9.0×10 -8 Pam 3 / s;

[0067] At 100°C and 15MPa, the leakage rate: 3.2×10 -7 Pam 3 / s.

Embodiment 3

[0069] Apply the above-mentioned helium leakage quantitative detection device and follow the above-mentioned steps to detect the helium leakage rate of the sealing equipment to be inspected--spherical structure equipment at a temperature of room temperature -700 ° C and a pressure of 0-1 MPa. The test results are as follows:

[0070] At room temperature and 0MPa, the leakage rate: 1.1×10 -10 Pam 3 / s;

[0071] At room temperature and 1MPa, the leakage rate: 9.8×10 -11 Pam 3 / s;

[0072] At 500°C and 0MPa, the leakage rate: 9.3×10 -10 Pam 3 / s;

[0073] At 500°C and 1MPa, the leakage rate is: 8.9×10 -10 Pam 3 / s.

[0074] At 750°C and 0MPa, the leakage rate: 2.7×10 -9 Pam 3 / s;

[0075] At 750°C and 1MPa, the leakage rate: 2.9×10 -9 Pam 3 / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com