Leak detecting method in production of large and medium-sized automobile air conditioner

An automotive air conditioner, large and medium-sized technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve problems affecting production and delivery timeliness, low output value per unit area of workshop The problem of high labor intensity of workers can reduce the occupation of warehouses, meet the needs of timely delivery, and improve the effect of leak detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation of the leak detection method during the production of large and medium-sized automobile air conditioners of the present invention will be further described below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

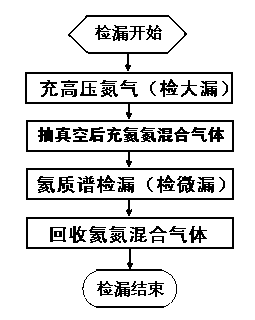

[0027] See attached figure 1 . The leak detection method during the production of large and medium-sized automobile air conditioners includes the following steps:

[0028] (1) Filling with high-pressure nitrogen (check for large leaks)

[0029] At the beginning of leak detection, use a helium-filled recovery device including an air compressor, a vacuum pump and a pressure sensor to fill the piping system of large and medium-sized automobile air conditioning components with nitrogen, so that the air pressure in the piping system of the component reaches 2400-2600KPa, ensuring Pressing time > 6s, the specific opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com