Cavity product airtightness detection table and detection method

A sealing detection and product technology, which can be used in the testing of fluid sealing, using liquid/vacuum for liquid tightness measurement, and by detecting the appearance of fluid at the leak point, which can solve the problems of low detection accuracy and poor reliability. , to achieve high detection accuracy, meet the requirements of sealing detection, and improve the efficiency of sealing detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

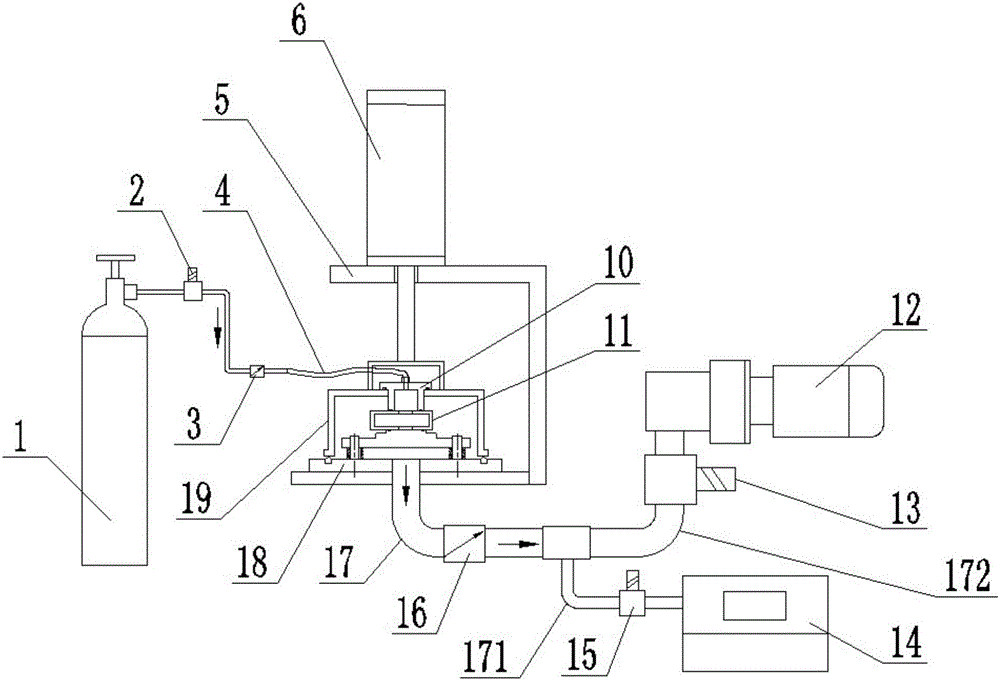

[0026] Such as figure 1 The chamber type product airtightness detection platform shown mainly includes a helium gas source 1, a helium mass spectrometer leak detector 14 and a sealing device, wherein the helium gas source 1 adopts a helium tank, and the specific structure of the sealing device Such as Figure 4 As shown, it mainly includes an indenter 10, a base 18 and a bell jar 19. The indenter 10 is a hollow cylinder with a T-shaped structure, and its relatively small end is inserted into the inner cavity of the bell jar 19. The bell jars 19 are sealed and fixed, and the base 18 and the bell jars 19 are movably connected, and the two can be separated from each other, or the bell jars 19 can go down relative to the base 18 until they are combined. Form a sealed connection. In order to more conveniently control the upward and downward movement of the bell 19 relative to the base 18 and save manpower, the cylinder 6 can be used to control the up and down movement of the bell...

Embodiment approach 2

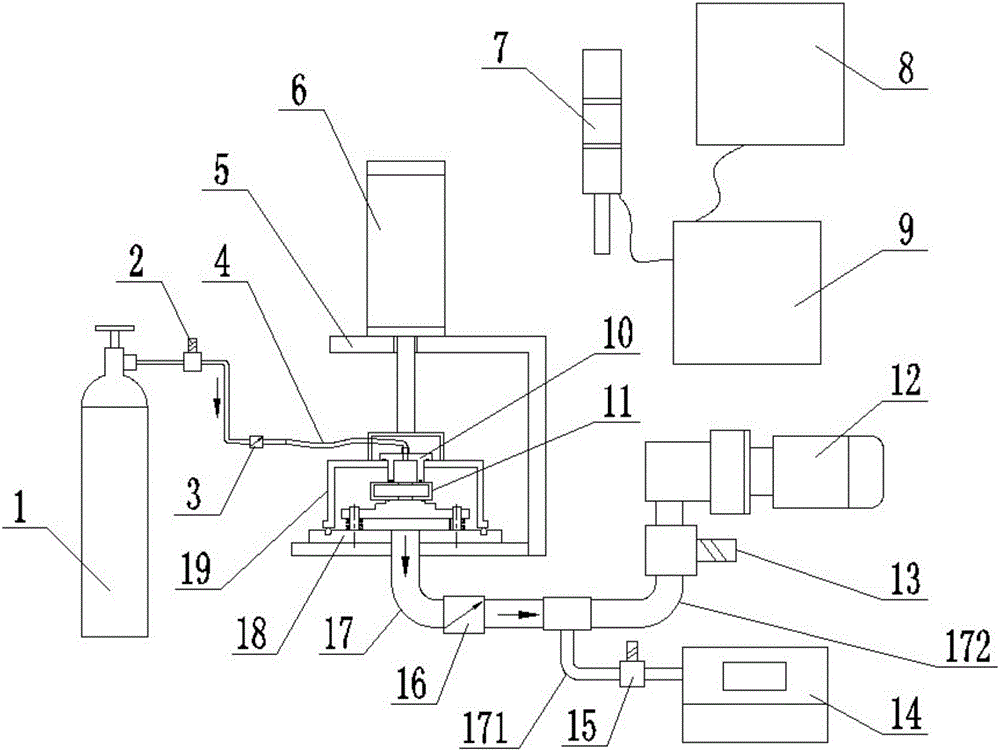

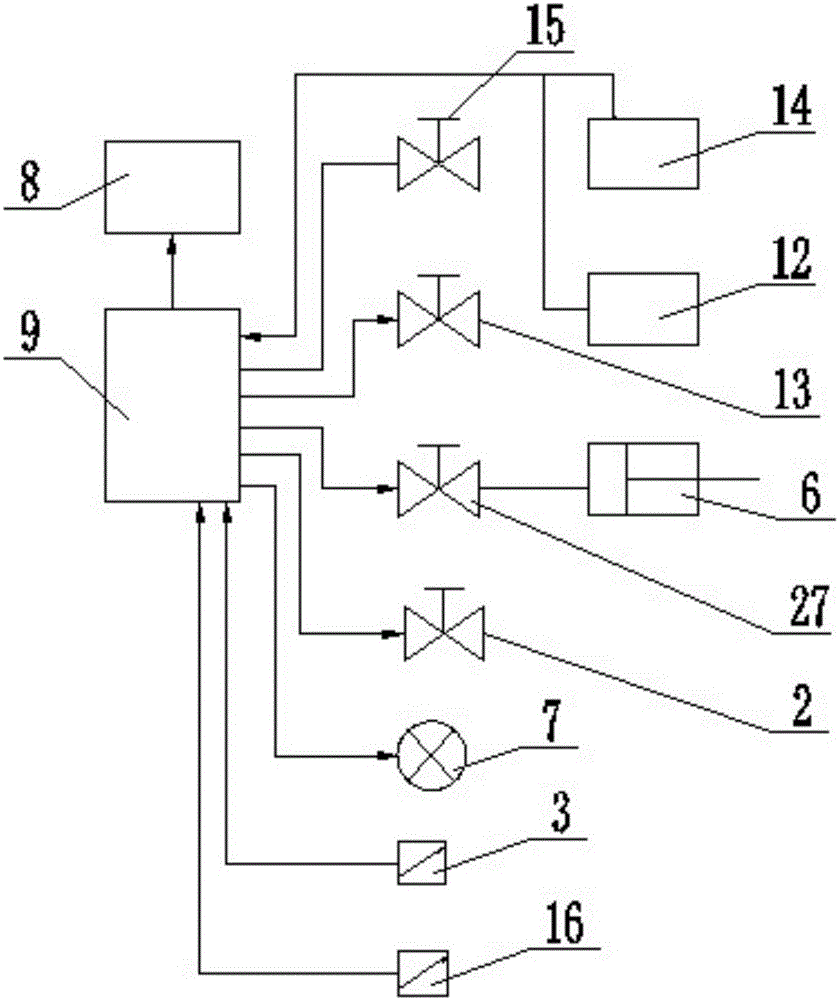

[0036] Such as figure 2 The shown cavity-type product airtightness testing platform also includes an alarm 7, a display 8 and a controller 9, a first pressure sensor 3 is set on the air intake duct 4, and a second pressure sensor 16 is set on the air suction duct 17 , the cylinder 6 uses a solenoid valve 27 to control its action. Wherein, the alarm 7 can be a photoelectric alarm, such as a three-color alarm lamp, or an audible alarm; the controller 9 can be a PLC, or a single-chip microcomputer, or an industrial computer. Such as image 3 As shown, the first pipeline valve 2, the second pipeline valve 13, and the third pipeline valve 15 all adopt electromagnetic valves, and are electrically connected with the controller 9 respectively; the display 8, the helium mass spectrometer leak detector 14, the vacuum pump 12. The alarm 7, the first pressure sensor 3, the second pressure sensor 16, and the solenoid valve 27 are electrically connected to the controller 9, respectively....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com