Leak detection test bed

A technology of leak detection test and test bench, which is applied in the field of detection test bench, can solve the problems of loose leak detection conditions and inaccurate detection data, and achieve the effect of perfect function, convenient operation and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

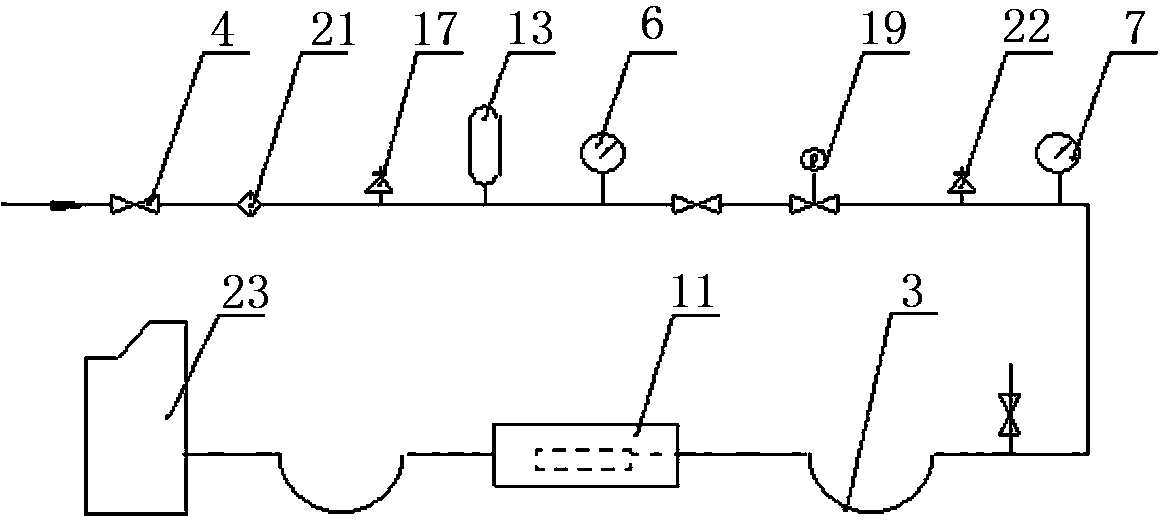

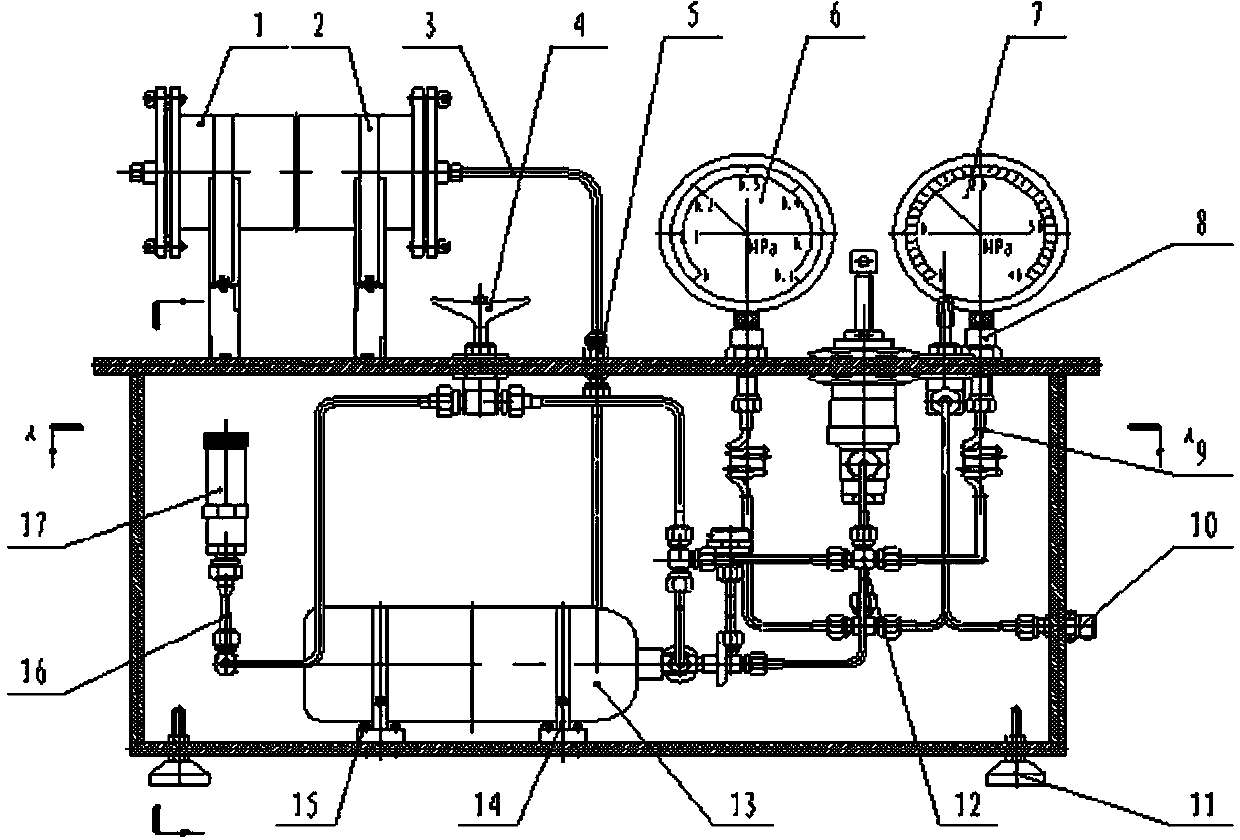

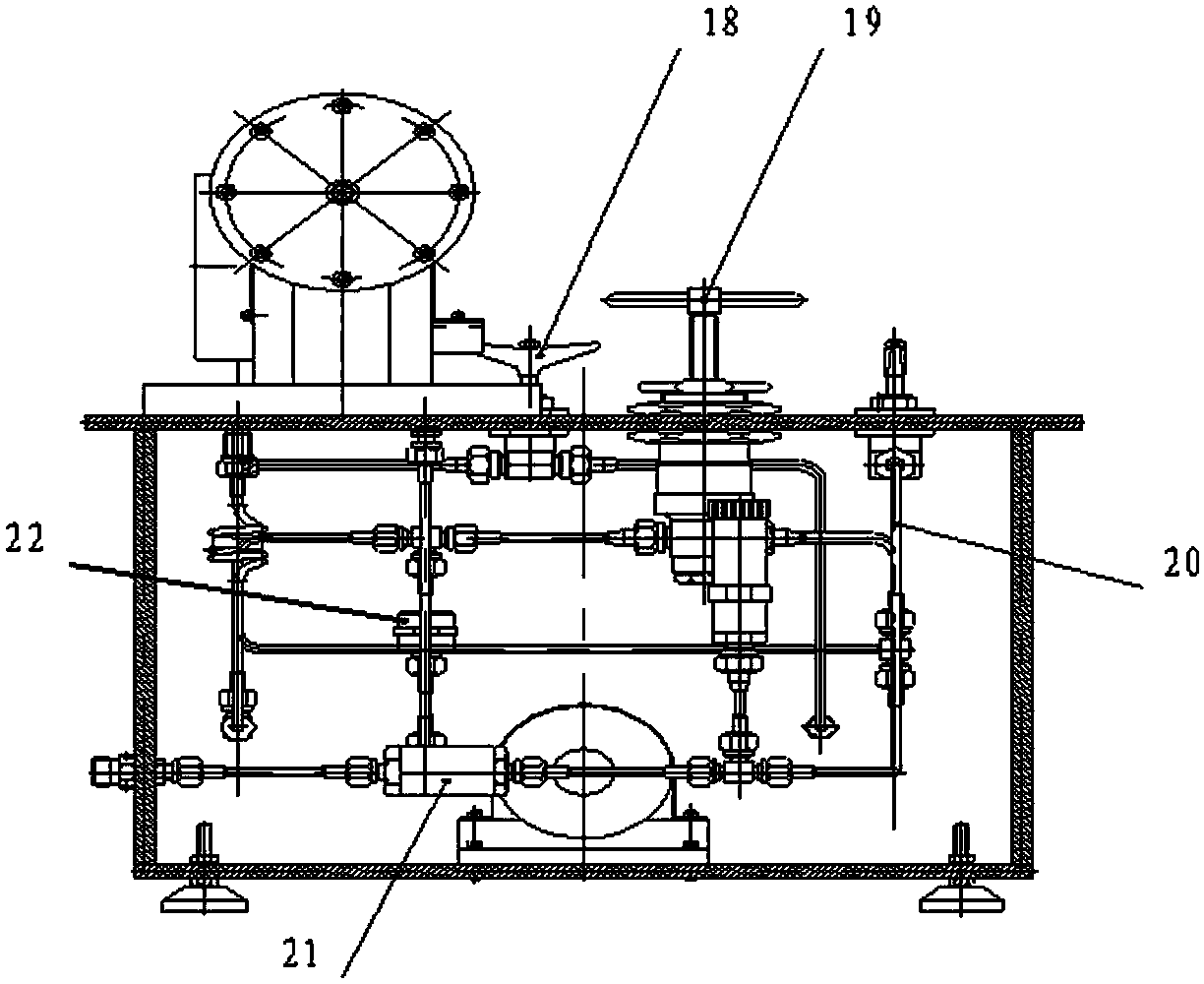

[0026] Such as Figure 1-5 As shown, the test bench includes two parts: the inflation pipeline and the vacuum working chamber; the inflation pipeline part, the inflation pipeline communicates with the gas storage bottle 13 through the filter 21, the high-pressure safety valve 17, and the manual shut-off valve 4; the gas storage The helium in the bottle passes through the decompression valve 19, the low-pressure safety valve 22, and connects the hose 3 through the inflation pipeline nozzle 5. The hose 3 communicates with the steel pipe of the component under test. connected to the helium mass spectrometer leak detector 23; the gas cylinder 13 is connected to the air inlet of the pressure reducing valve and then connected to the low-pressure pipeline through the outlet of the pressure reducing valve, and a low-pressure pressure gauge 6 and a high-pressure pressure gauge 7 are installed on the low-pressure pipeline The high pressure gauge 7 and the low pressure gauge 6 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com