Vacuum coating cavity leak detection system and leak detection method

A technology of vacuum coating and vacuum cavity, which is applied in the direction of liquid tightness measurement and fluid tightness test using liquid/vacuum degree, and detection of fluid appearance at leakage points, etc., which can solve high pollution, low vacuum degree, It is difficult to detect leaks and other problems, and achieve the effect of high leak detection sensitivity, simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

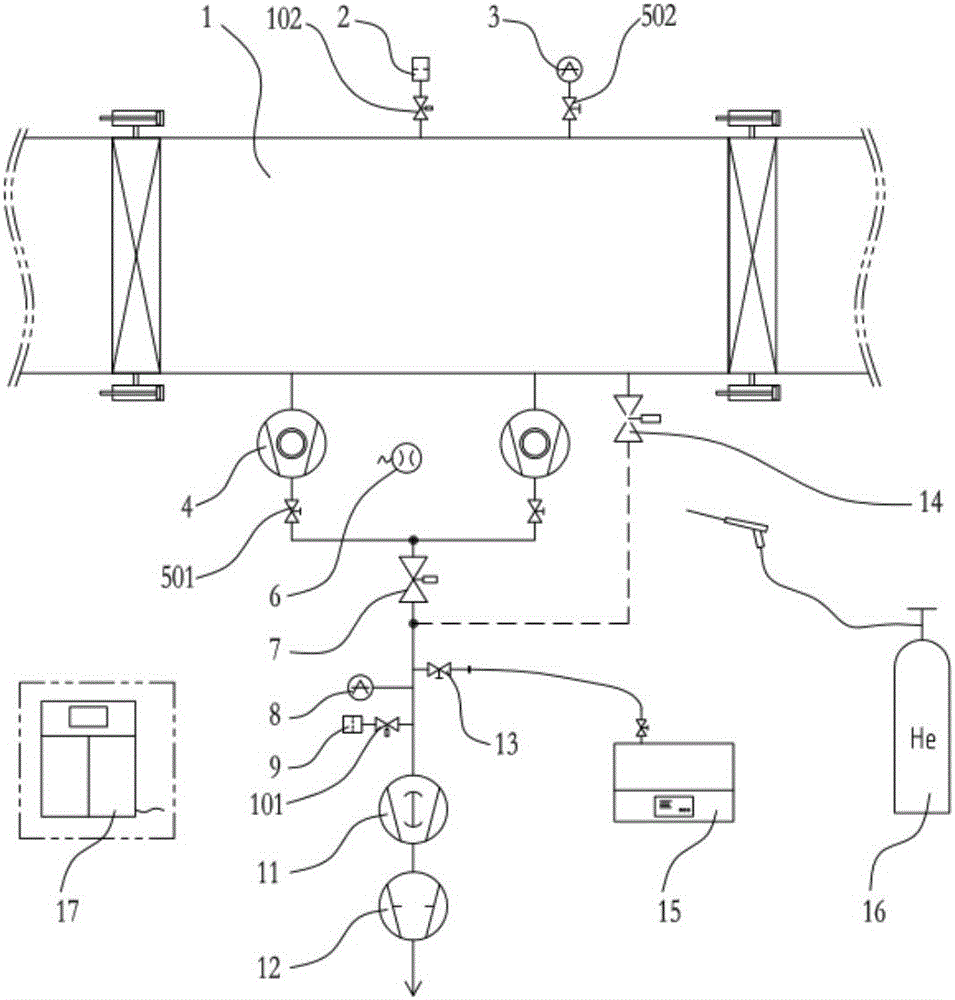

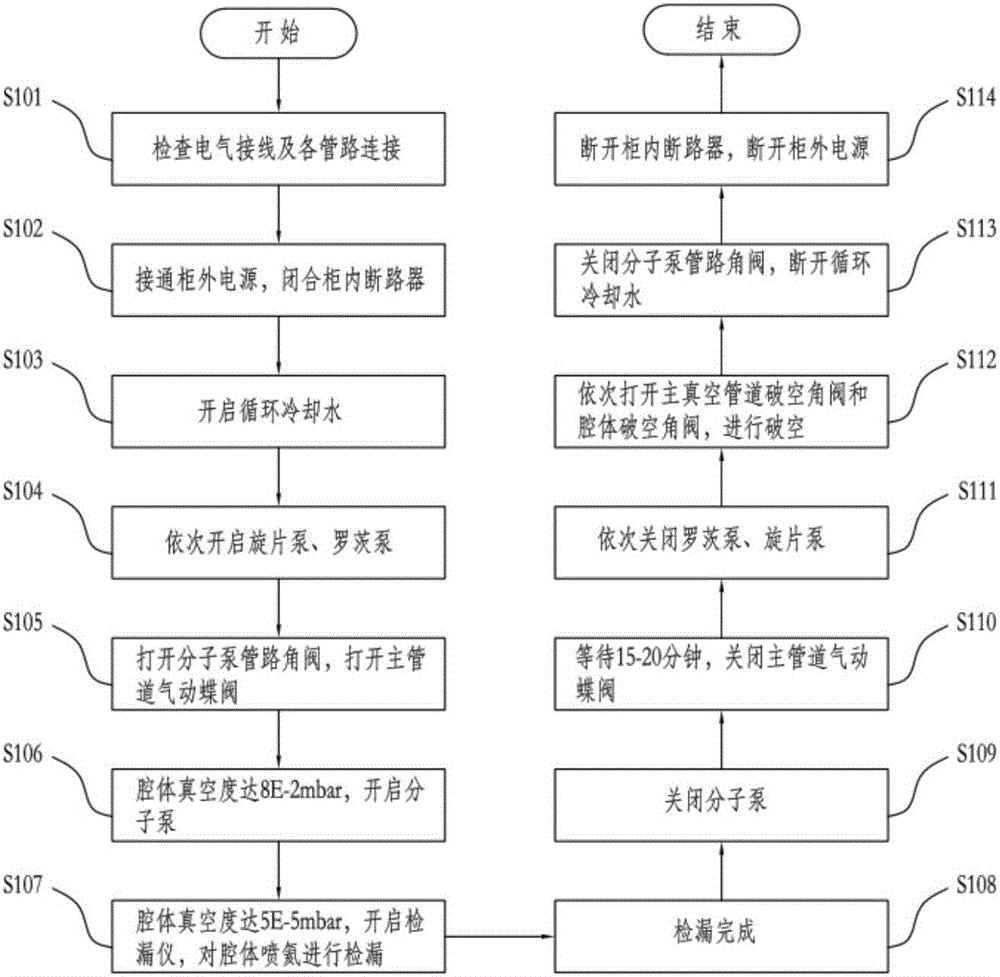

[0039]A leak detection system for a vacuum coating chamber, comprising: a vacuum chamber to be inspected 1, a leak detection device, and an electric control system. The side wall of the vacuum chamber 1 to be tested is equipped with a breaking device I2 and a vacuum detection element I3, and the leak detection device includes a high vacuum pump 4, a backing pump group I11, a backing pump group II12, a high vacuum butterfly valve I7, a vacuum detection Component II8, air breaking device II9, helium mass spectrometer leak detector 15, helium injection system 16 and electronic control system 17, the high vacuum pump 4 is directly installed on the side wall of the vacuum chamber 1 to be checked through the flange, the backing pump group I11, the backing pump group II12 are connected in series through the vacuum pipeline, and then connected in series with the high vacuum pump 4 through the high vacuum butterfly valve I7; the vacuum detection element II8 and the air breaking device I...

Embodiment 2

[0044] A leak detection system for a vacuum coating chamber, comprising: a vacuum chamber to be inspected 1, a leak detection device, and an electric control system. The side wall of the vacuum chamber 1 to be inspected is equipped with a breaking device I2 and a vacuum detecting element I3, and the leak detecting device includes a Roots pump, a rotary vane pump or a screw pump, a high vacuum butterfly valve II14, a vacuum detecting element II8, a breaking hole Device II9, helium mass spectrometer leak detector 15, helium injection system 16 and electronic control system 17, Roots pump, rotary vane pump or screw pump are connected in series through vacuum pipelines, and then connected to the vacuum chamber 1 to be tested through high vacuum butterfly valve II14; The vacuum pipeline between the high-vacuum butterfly valve II14 and the Roots pump is equipped with a vacuum detection element II8 and a void breaking device II9. On the cavity 1 and the vacuum pipeline, the pneumatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com