Method for lamination of an electrical strip for transformer cores

A technology of core silicon steel and silicon steel sheet, which is applied in transformer/inductor parts, inductor/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of large mechanical load of materials, reduce the electromagnetic characteristics of iron core silicon steel sheet, etc., and achieve eddy current loss Reduced, reduced eddy current, high mechanical stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

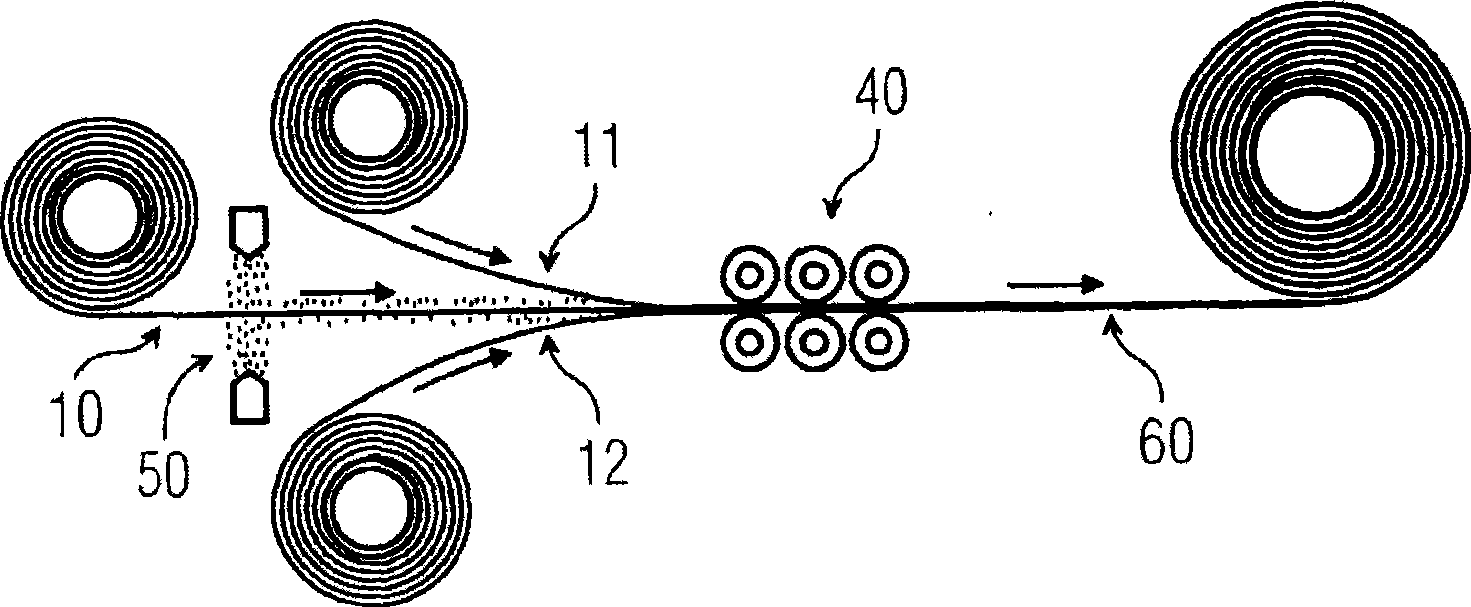

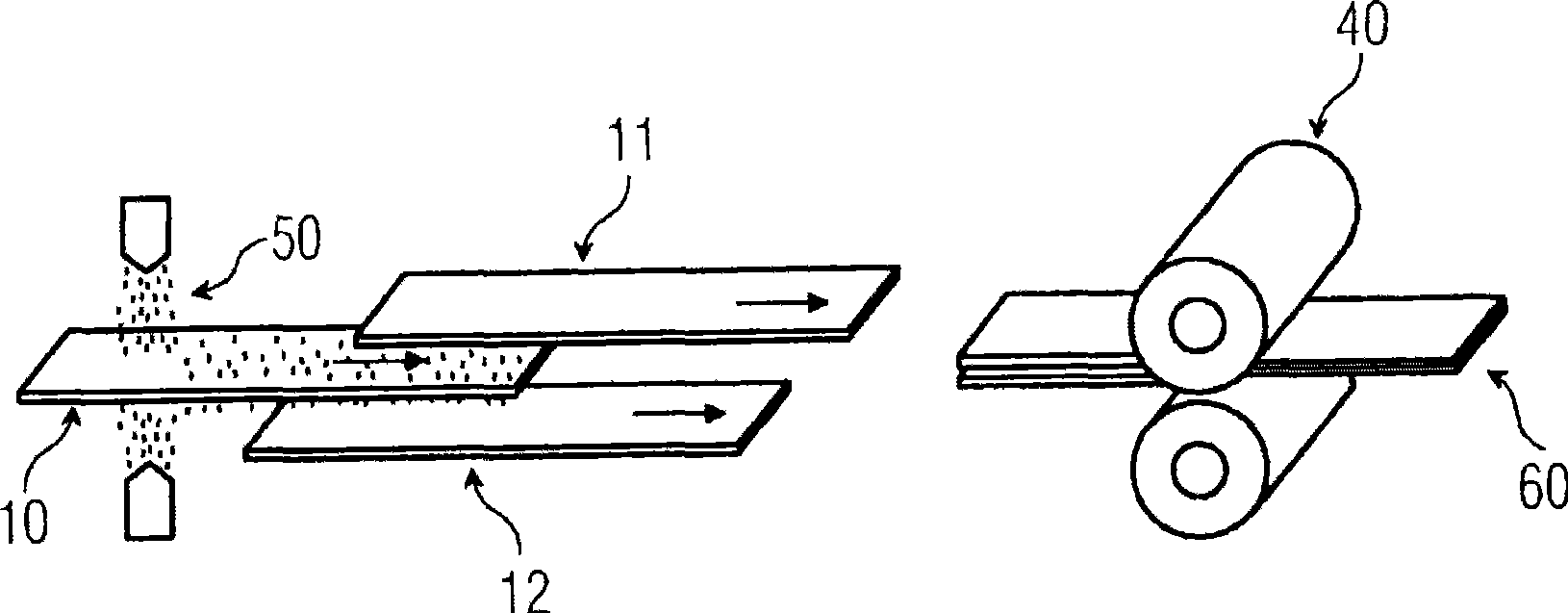

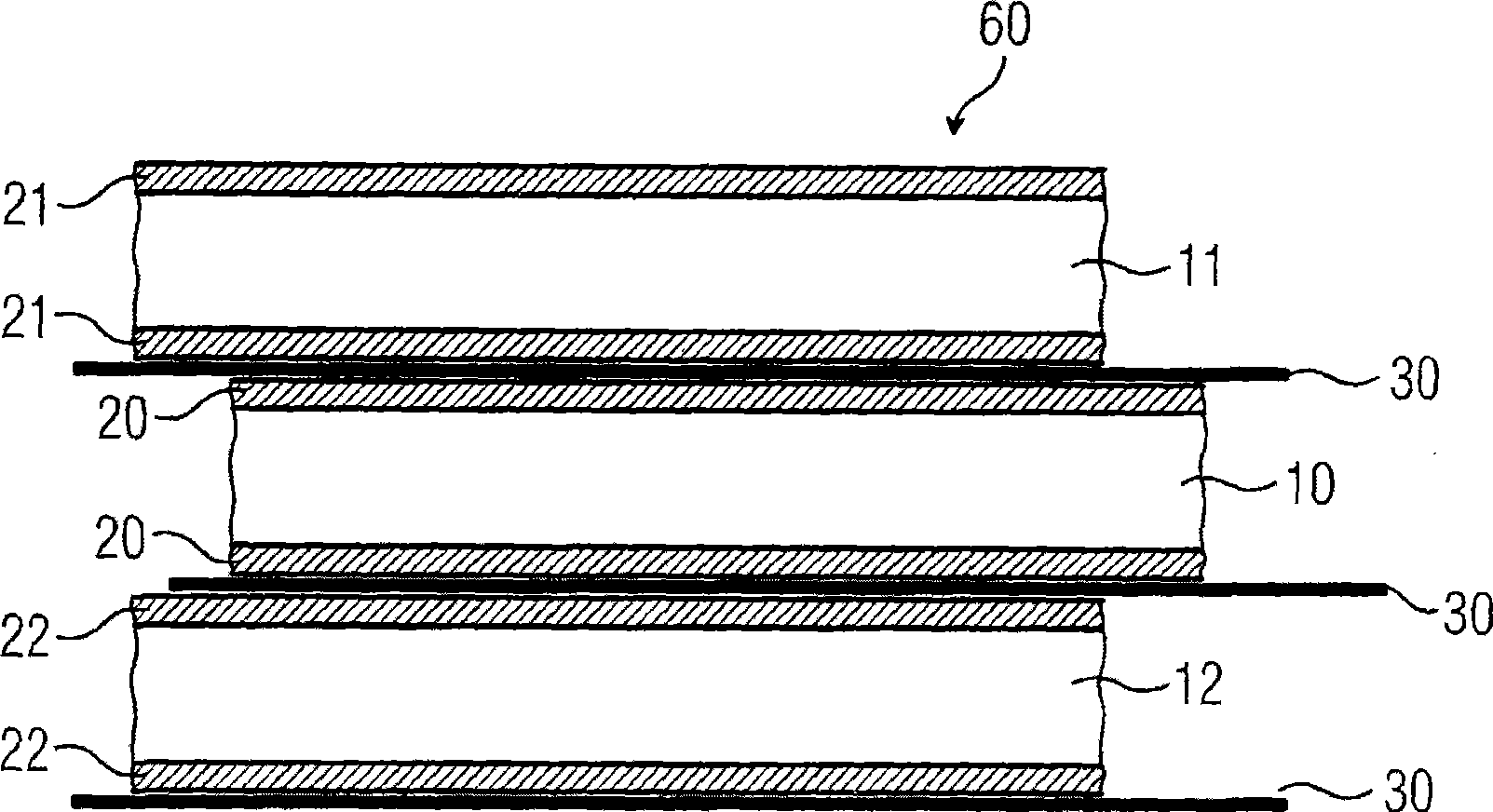

[0027] figure 1 A schematic diagram showing the manufacturing method of laminated silicon steel sheets 10, 11, 12 according to the present invention. A central silicon steel sheet 10 is sprayed with a fixing agent 50 and either already has a metallurgically treated surface or has an additionally applied insulating layer 20 (not shown). The adhesive material applied to the outer insulating layer of the central silicon steel sheet 10 forms the connection layer 30 , on which the other silicon steel sheets 11 , 12 are applied on the upper and lower sides of the central silicon steel sheet 10 . Between the insulating layers 20, 21, 22 of each silicon steel sheet 10, 11, 12, the connection layer 30 formed in this way is compacted by a pressure roller 40, and thus a permanent and long-lived connectivity layers. Thus, on the one hand, the mechanical stability of the produced core silicon steel sheet 60 is achieved. In addition, the lamination structure of the silicon steel sheets 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com