Reciprocating motor

A motor and reciprocating technology, applied in electric components, reciprocating/swinging/vibrating magnetic circuit components, electromechanical devices, etc., can solve problems such as difficulty in ensuring the roundness of the magnet frame, deformation of the slit, and reduction in molding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, embodiments of a reciprocating motor according to the present invention will be described with reference to the accompanying drawings.

[0033] There are various embodiments of the reciprocating motor according to the present invention, therefore, only preferred embodiments will be described below.

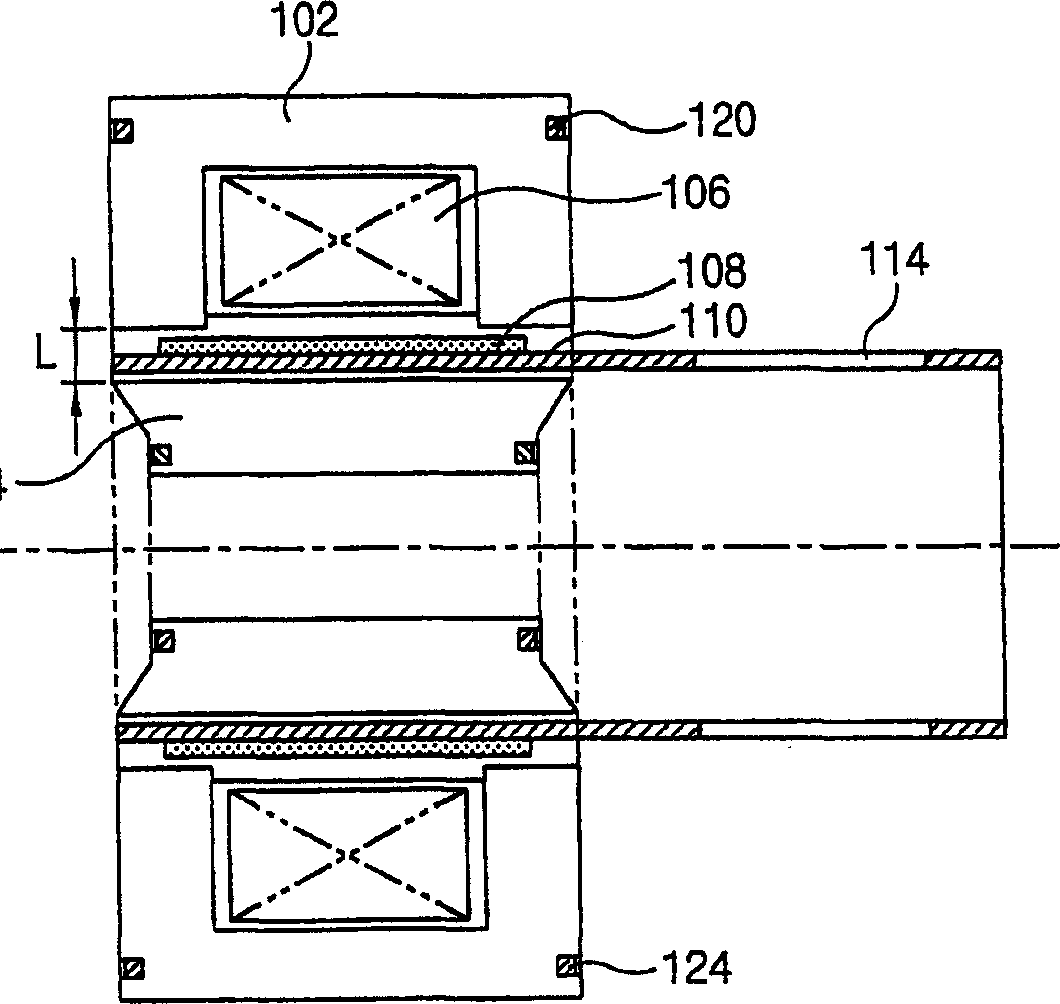

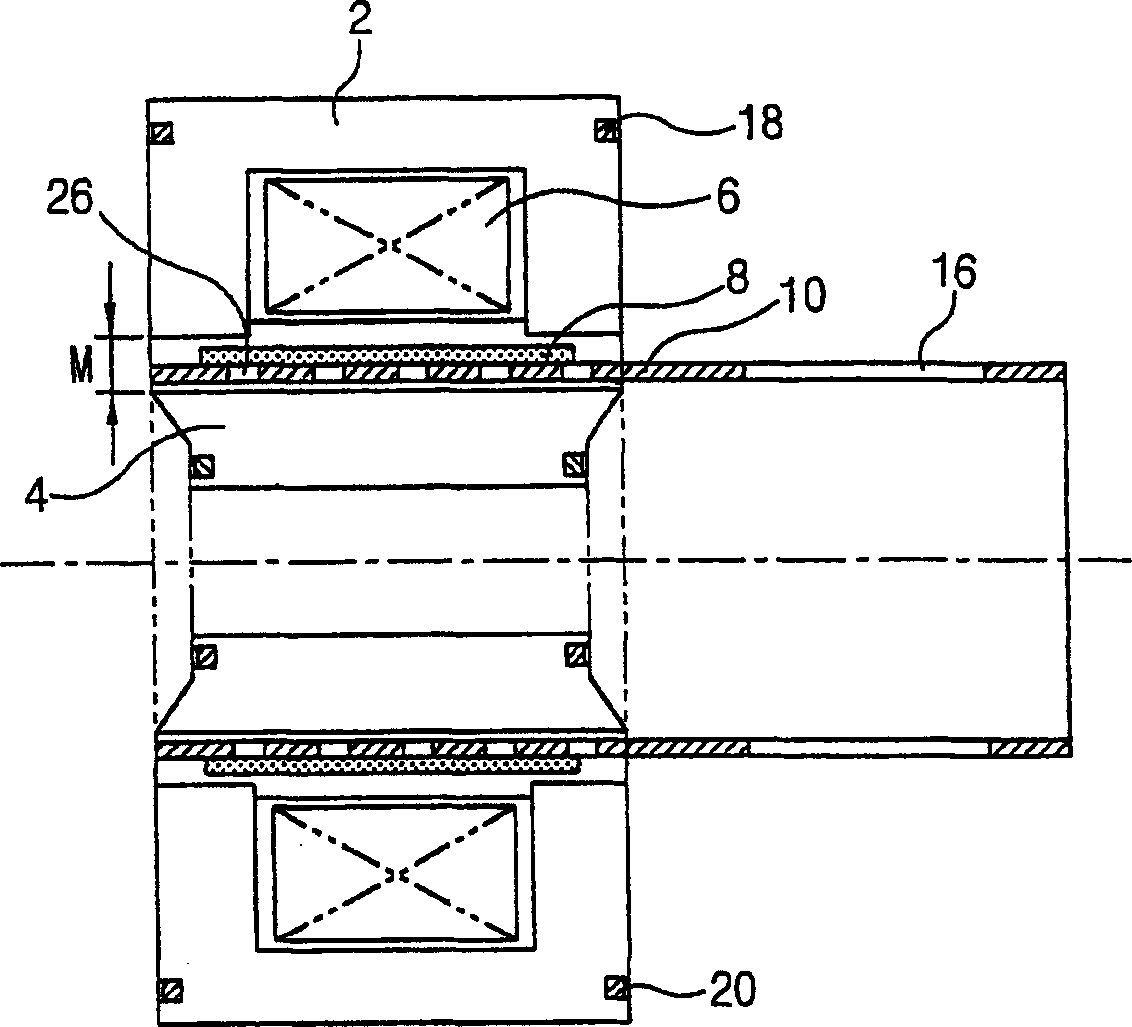

[0034] image 3 is a sectional view showing a reciprocating motor according to the present invention.

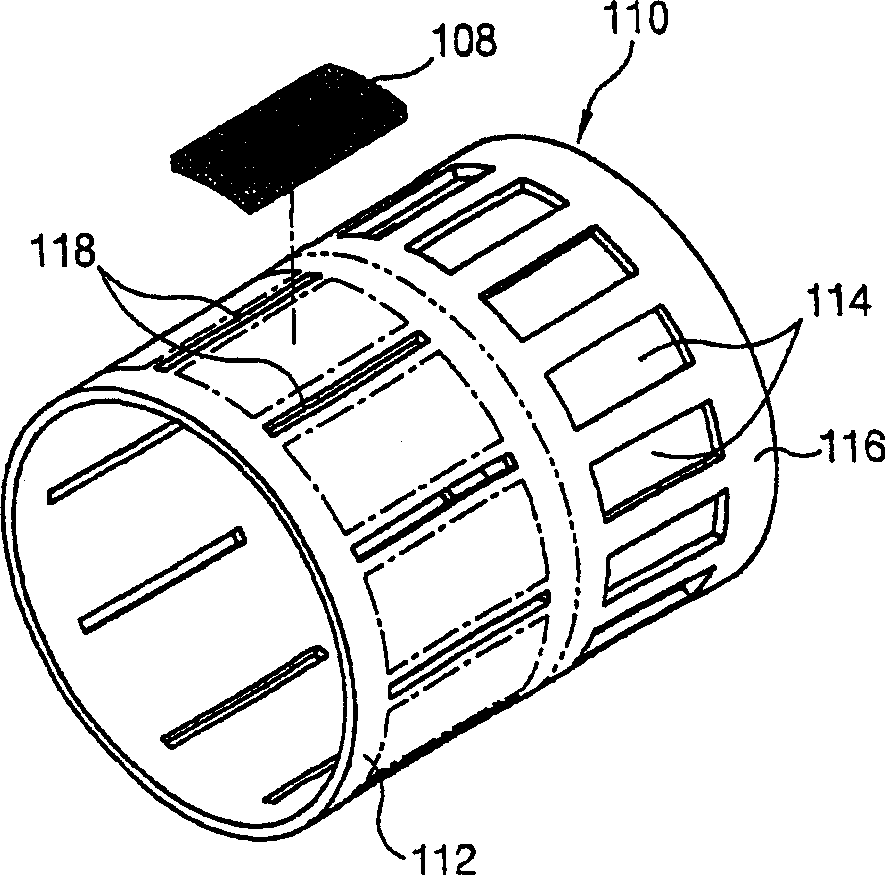

[0035] The reciprocating motor according to the present invention includes: a cylindrical outer stator 2, which is fixed to a housing (not shown in the figure); an inner stator 4, which is positioned on the outer stator 2 with a predetermined air gap M inner peripheral surface, and can form a magnetic flux between itself and the outer stator 2; a coil 6, which is either wound on the outer stator 2, or is wound on the inner stator 4; a magnet 8, which is positioned to be able to Perform linear motion between the outer stator 2 and the inner stator 4; and a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com