Extractor hood

A range hood and fan technology, applied in the field of range hoods, can solve the problems of zero leakage of oil fume, increased noise, occupying cooking space, etc., and achieve the effects of improving work efficiency, reducing eddy current loss, and improving filtering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

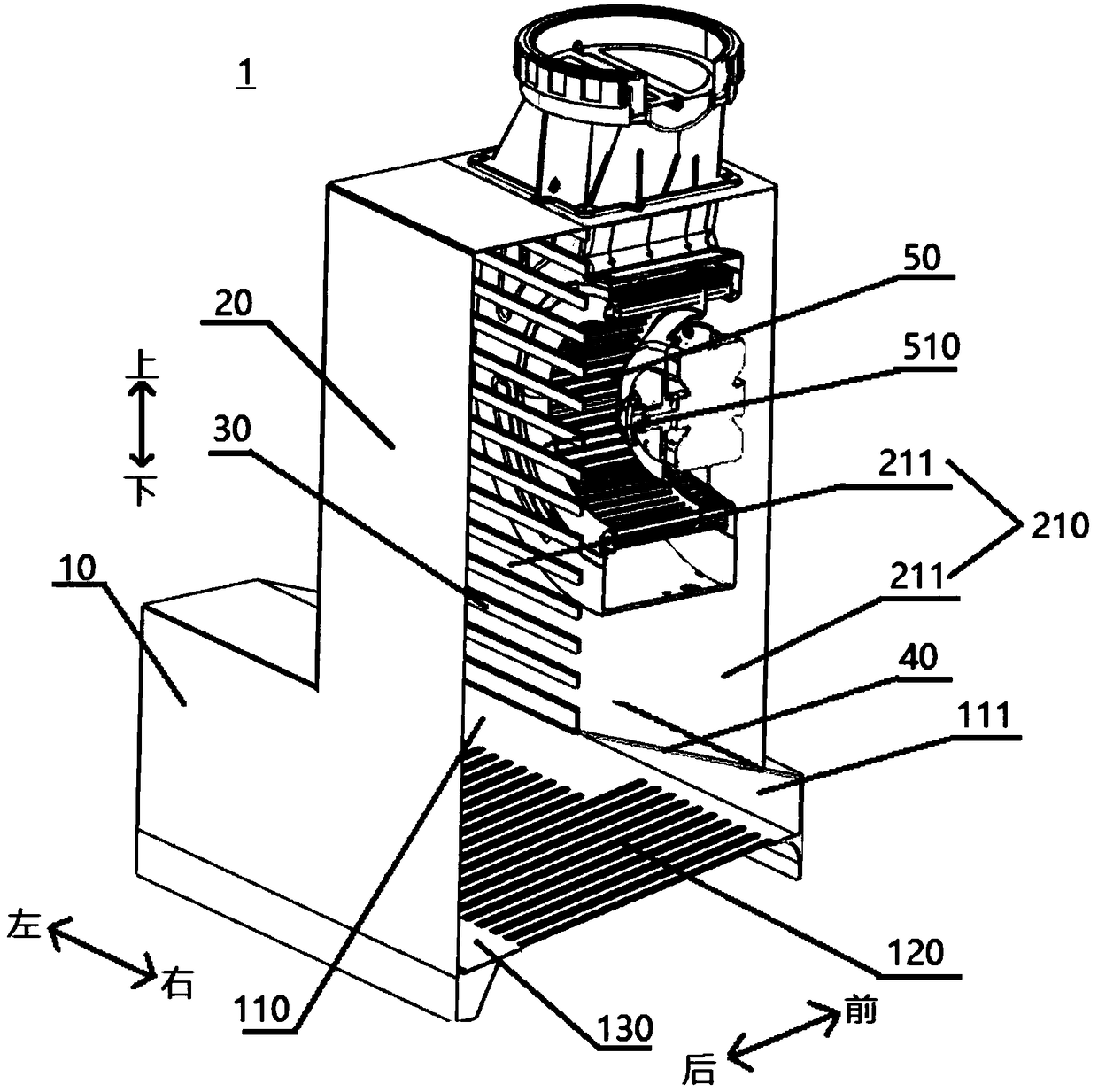

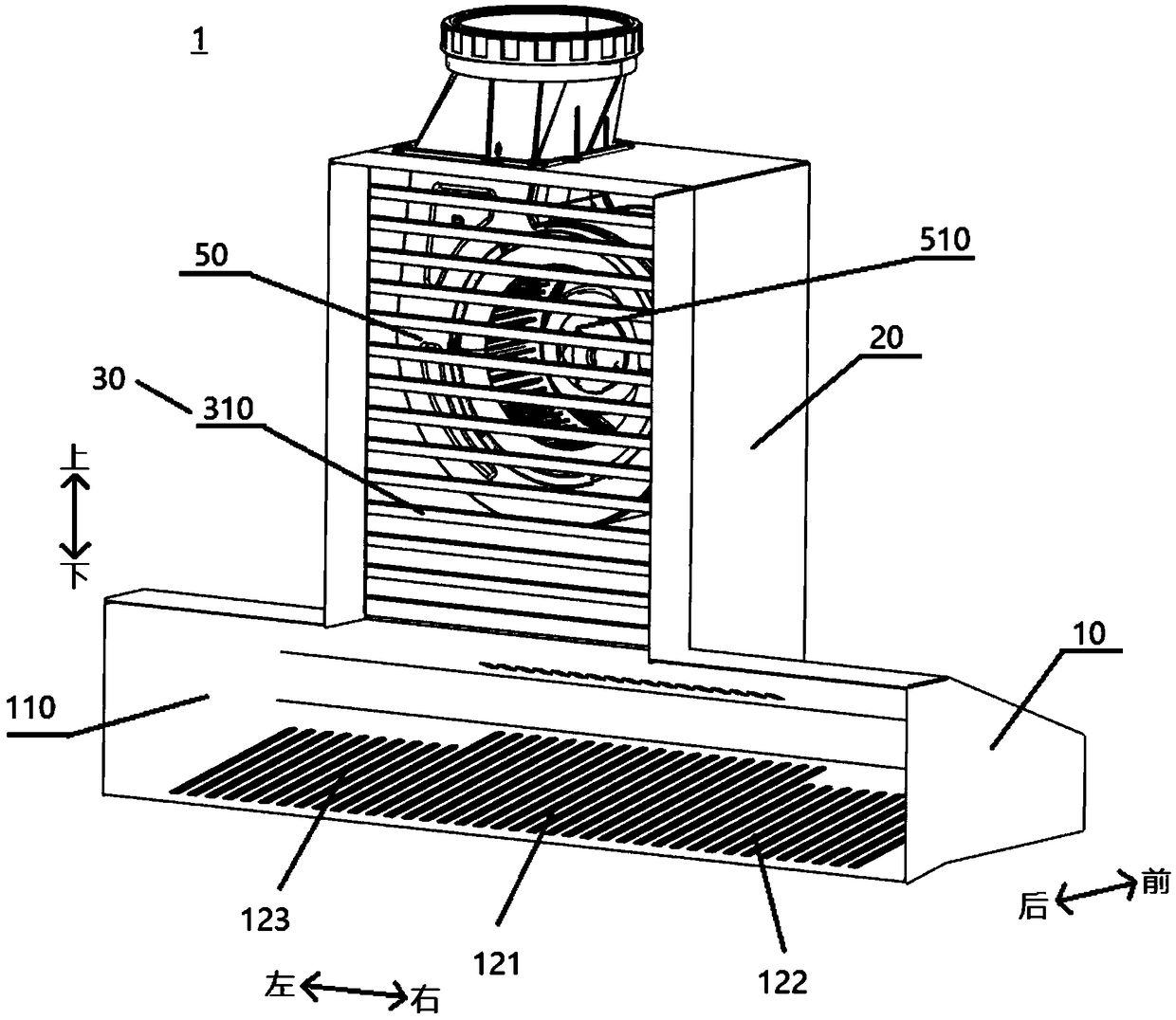

[0074] Such as Figure 1-Figure 5 As shown, the range hood 1 of this embodiment includes a fan hood 20 , a smoke collecting hood 10 , a splitter plate 30 and a central deflector plate 40 . The fan cover 20 defines a fan cavity 210, the fan cavity 210 is provided with a fan 50, the smoke collection cover 10 is located below the fan cover 20, and defines a smoke collection cavity 110 communicated with the fan cavity 210, the smoke collection cavity 110 has a function to collect oil fumes. The oil fume inlet 120, the splitter plate 30 is set in the fan chamber 210 to divide the fan chamber 210 into two sub-chambers 211 distributed along the air inlet direction of the fan 50, and the fan 50 is arranged in the front side sub-cavity 211.

[0075] The splitter plate 30 is arranged corresponding to the air inlet 510 of the fan 50. The splitter plate 30 includes two installation bars and a plurality of grill bars 310, the two installation bars are arranged opposite to each other, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com