Twisted diffusion cylinder and axial-flow fan applying same

A technology of diffuser and fan, applied in the field of ventilation, can solve the problems of reducing airflow speed, energy efficiency of axial flow fan, limited improvement of noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

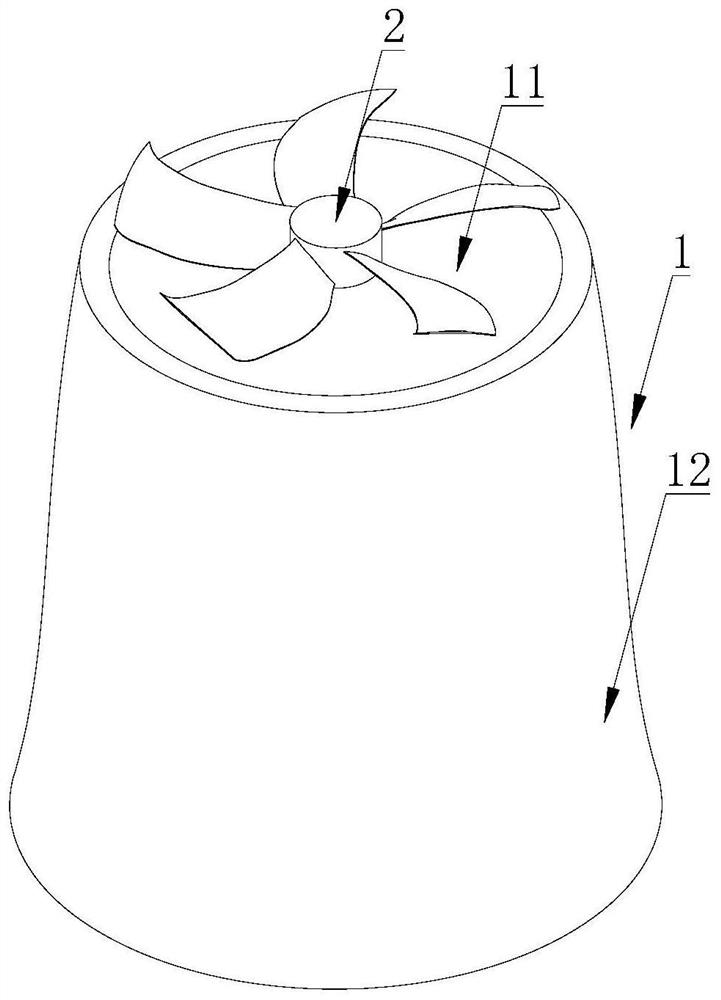

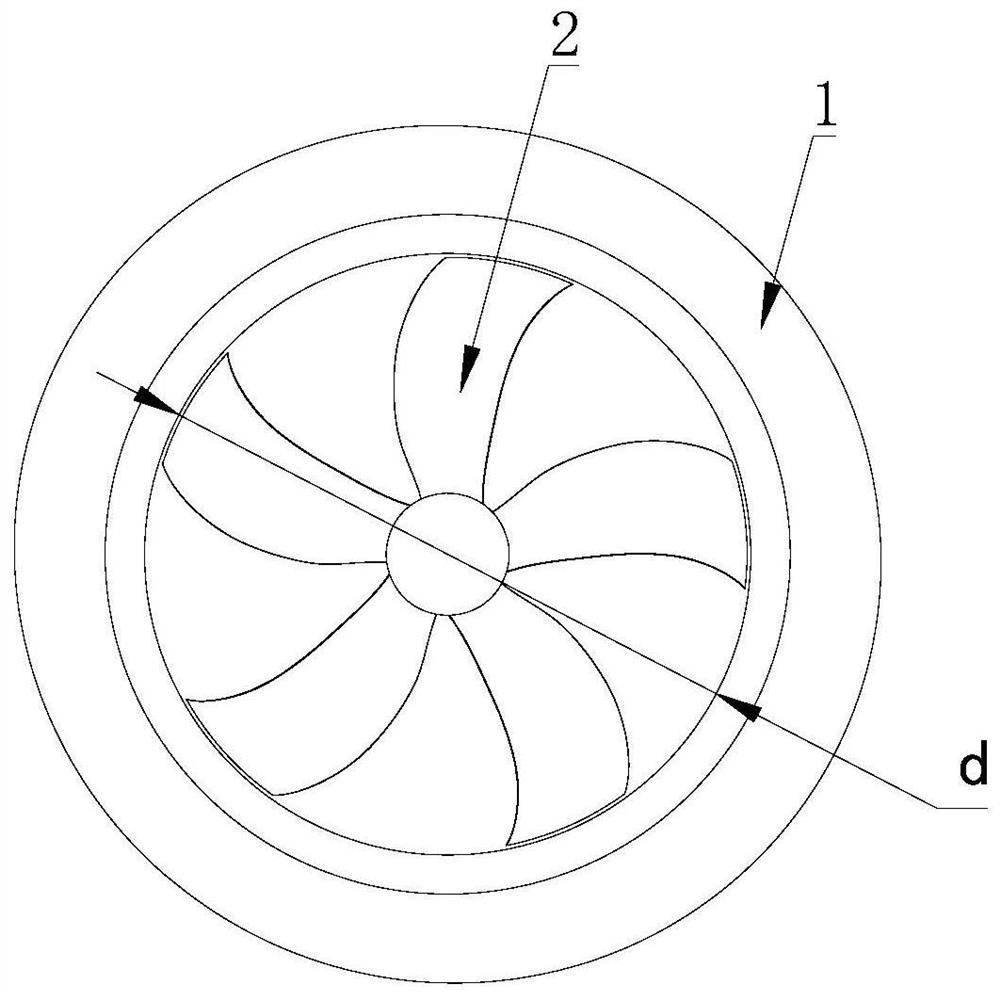

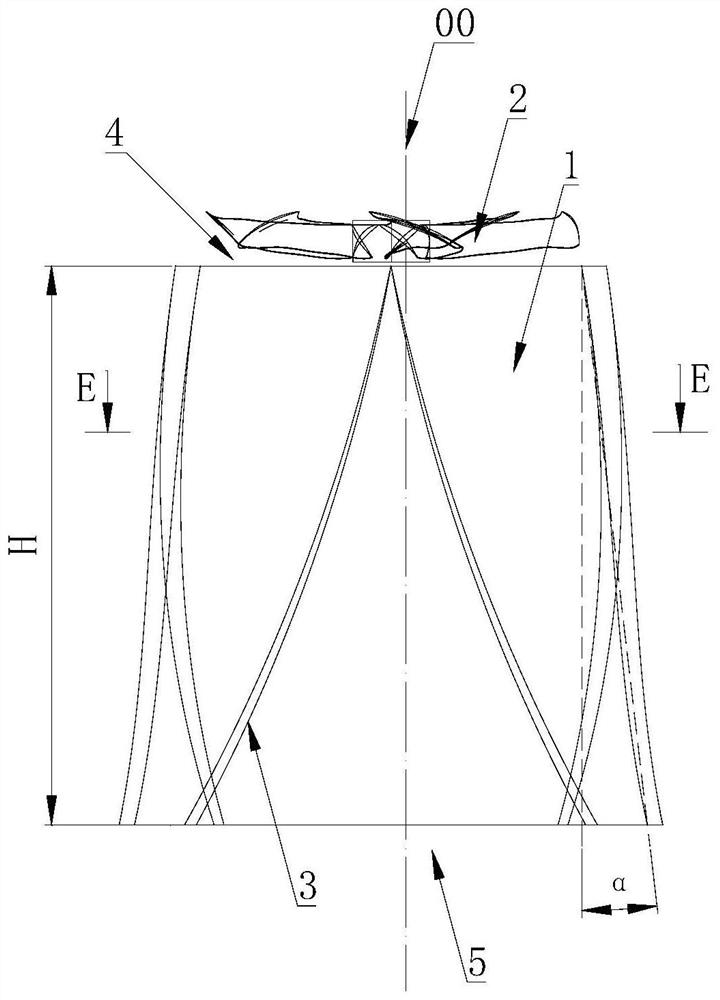

[0025] refer to Figure 1-4 , this embodiment discloses a twisted diffuser cylinder, which includes a cylinder body 1, the cylinder body 1 is provided with through ventilation holes along the axis 00 direction, the cylinder body 1 is set with equal wall thickness, and the two ends of the cylinder body 1 along the axis 00 direction are respectively It is the air inlet end 4 and the air outlet end 5. The side of the cylinder body 1 facing the axis 00 is the inner wall surface 11, and the side of the cylinder body 1 away from the axis 00 is the outer wall surface 12. The inner wall surface 11 and the outer wall surface 12 are arranged opposite to each other along the axis 00 From the air inlet end 4 to the air outlet end 5, the inner wall surface 11 gradually increases in cross-sectional area perpendicular to the axis 00;

[0026] The cylinder 1 is twisted along the coaxial helix 3, and is arranged along the axis 00 from the air inlet end 4 to the air outlet end 5. The cylinder 1...

Embodiment 2

[0038] refer to Figure 1-4 , the current collector is hidden in the figure, and this embodiment also discloses an axial flow fan, including a wind wheel 2 and a current collector, and the current collector is coaxially sleeved outside the wind wheel 2;

[0039] It also includes the above-mentioned twisted diffusion cylinder, the cylinder body 1 is coaxially arranged with the current collector, and the air inlet end 4 of the cylinder body 1 is connected to the air outlet of the current collector. The diameter of 4 is equal to the inner diameter of the current collector, and the helical direction of the helix 3 is opposite to that of the wind wheel 2 when it works.

[0040] The axial flow fan adopts a twisted diffuser cylinder. Since the cylinder 1 is twisted along the coaxial helix 3, and the rotation direction of the wind wheel 2 is opposite to that of the helix 3, when the airflow flows from the air outlet of the collector to the cylinder 1, the air flow generates a reverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com