Sleeve magnetism-gathering magnetic circuit structure used for permanent magnetism eddy transmission apparatus

A transmission device, permanent magnet eddy current technology, applied in the direction of electromechanical transmission device, electromechanical device, electric components, etc., can solve the problems of frequent decoupling, demagnetization, permanent magnet damage, etc., to achieve less eddy current loss, less permanent magnet material, manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

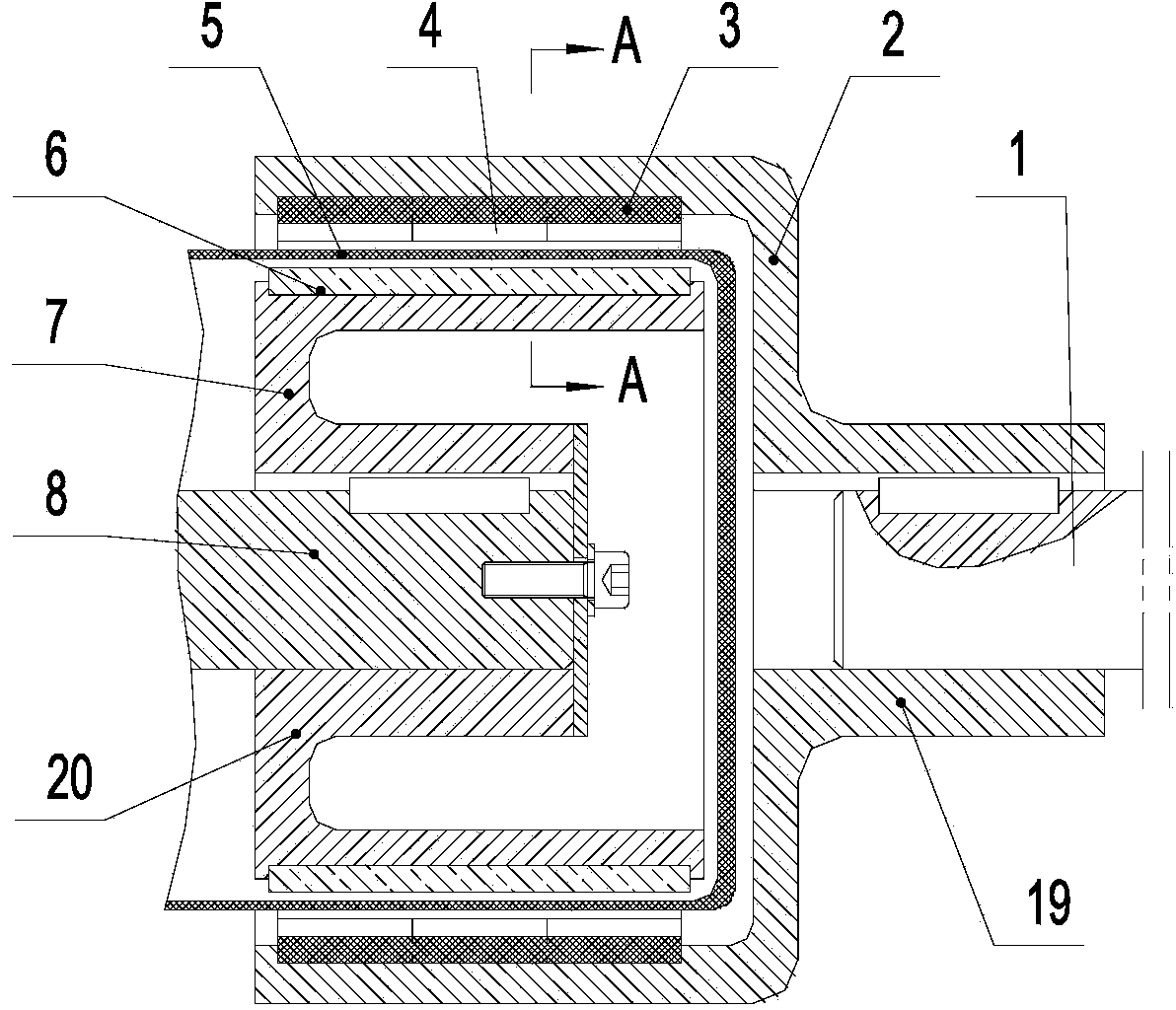

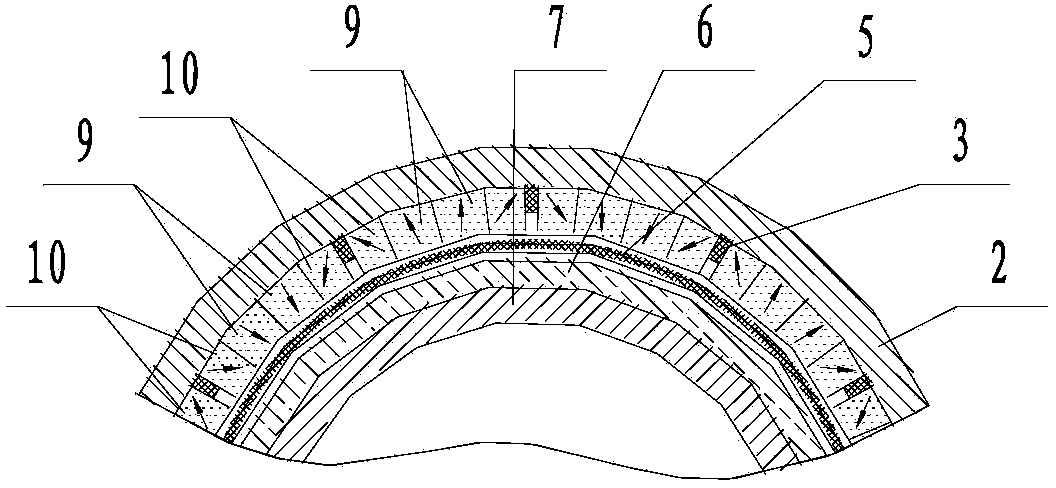

[0027] Such as figure 1 , figure 2 As shown, a sleeve-type magnet-concentrating magnetic circuit structure for a permanent magnet eddy current transmission device includes a permanent magnet rotor as the first outer rotor 19 and an eddy current ring rotor as the first inner rotor 20. The permanent magnet rotor consists of The cylindrical first outer rotor body 2 is composed of twelve sets of first permanent magnet groups 4, and the first permanent magnet groups 4 are bonded and fixed on the inner surface of the first outer rotor body 2 by magnetically conductive glue; the eddy current ring The rotor is composed of a cylindrical first inner rotor body 7 and a vortex ring 6. The vortex ring 6 is a circular structure made of copper material. The vortex ring 6 is arranged on the side wall of the first inner rotor body 7 through thermal expansion connection. On the outer surface, the first permanent magnet group 4 corresponds to the eddy current ring 6, and there is a gap between...

Embodiment 2

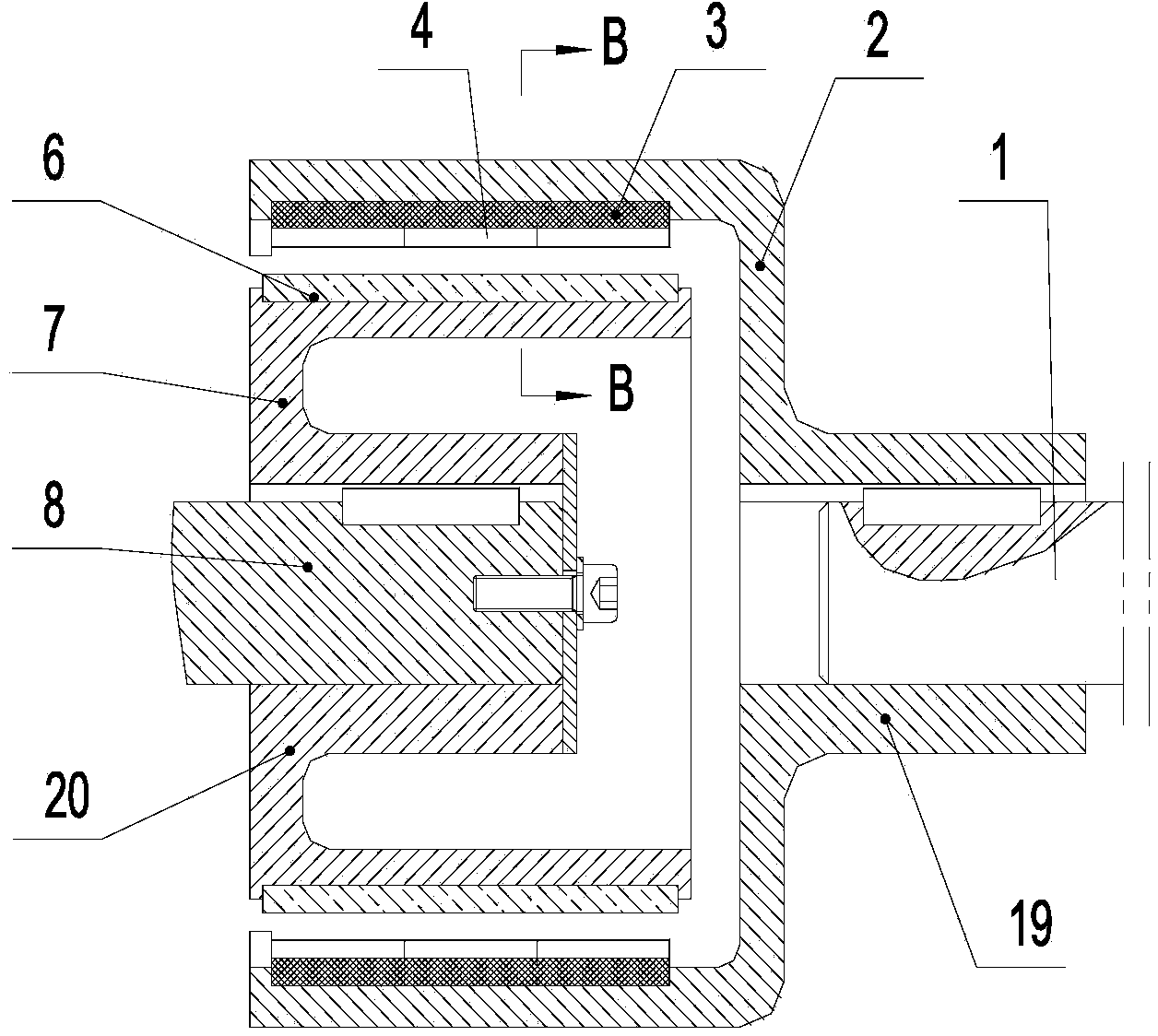

[0032] Such as image 3 , Figure 4 As shown, a sleeve-type magnet-concentrating magnetic circuit structure for a permanent magnet eddy current transmission device includes a permanent magnet rotor as the first outer rotor 19 and an eddy current ring rotor as the first inner rotor 20. The permanent magnet rotor consists of The cylindrical first outer rotor body 2 is composed of eighteen sets of first permanent magnet groups 4, and the first permanent magnet groups 4 are bonded and fixed on the inner surface of the first outer rotor body 2 by magnetically conductive glue; the eddy current ring The rotor is composed of a cylindrical first inner rotor body 7 and a vortex ring 6. The vortex ring 6 is a circular structure made of copper material. The vortex ring 6 is arranged on the side wall of the first inner rotor body 7 through thermal expansion connection. On the outer surface, the first permanent magnet group 4 corresponds to the eddy current ring 6, and there is a gap betwe...

Embodiment 3

[0037] Such as Figure 5 , Image 6 As shown, a sleeve-type magnet-concentrating magnetic circuit structure for a permanent magnet eddy current transmission device includes an eddy current ring rotor as the second outer rotor 21 and a permanent magnet rotor as the second inner rotor 22. The eddy current ring rotor consists of The cylindrical second outer rotor body 14 is composed of a vortex ring 6, the vortex ring 6 is an annular structure made of copper material, and the vortex ring 6 is fixed on the inner surface of the cylinder wall of the second outer rotor body 14 by screws; The permanent magnet rotor is composed of a cylindrical second inner rotor body 16 and twelve sets of second permanent magnet groups 15, and the second permanent magnet groups 15 are bonded and fixed on the outer surface of the side wall of the second inner rotor body 16 by magnetically conductive glue. The second permanent magnet group 15 is corresponding to the eddy current ring 6, and there is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com