Epoxy resin pouring shielding cylinder of transformer

A technology of epoxy resin and shielding cylinder, which is applied in the direction of preventing/reducing unnecessary electric/magnetic influences, and can solve problems such as difficult process guarantee, potential safety hazards of transformer operation, and difficult operation, so as to improve the insulation withstand voltage level, Easy operation and assembly, reliable effect of ground shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

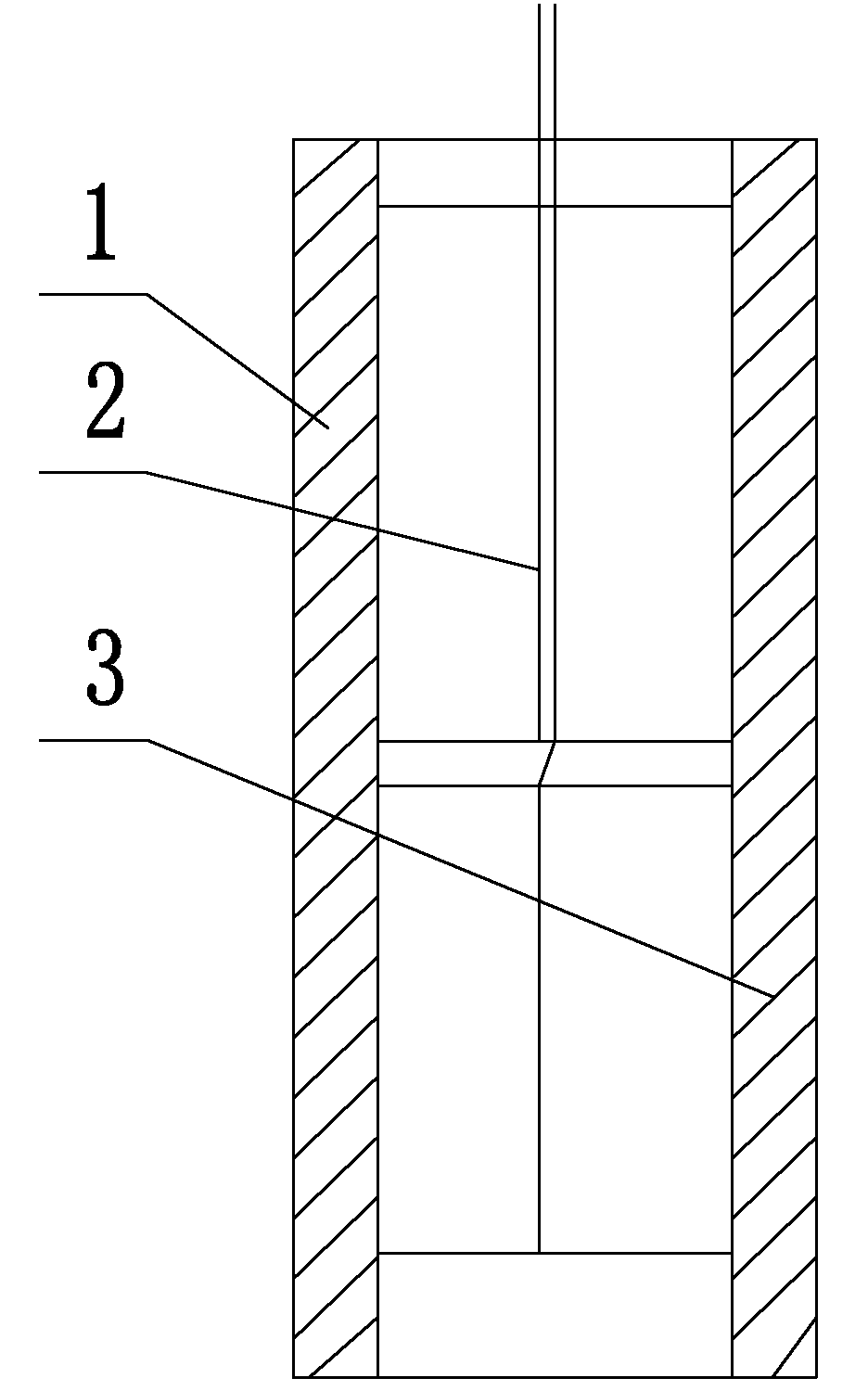

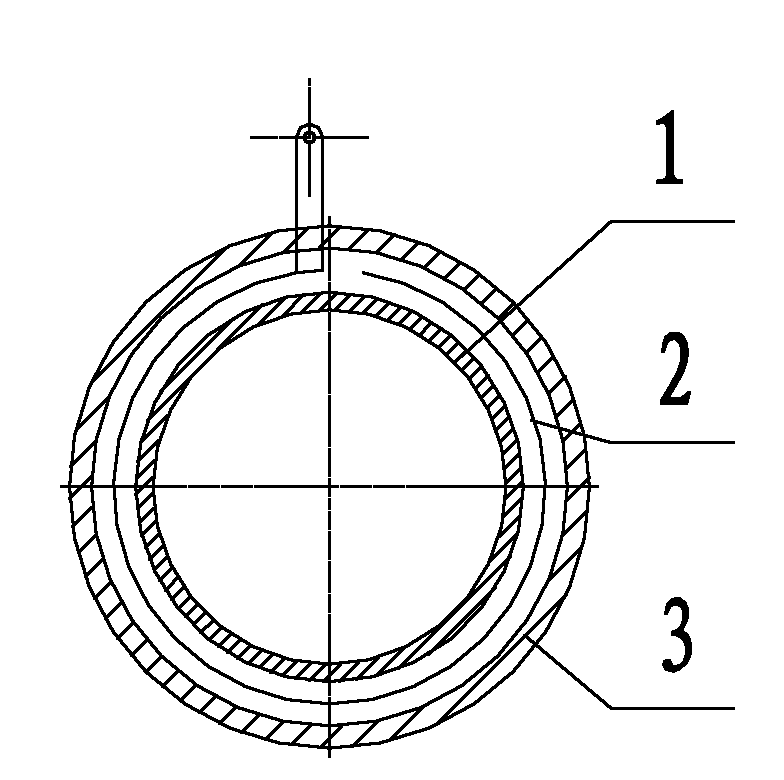

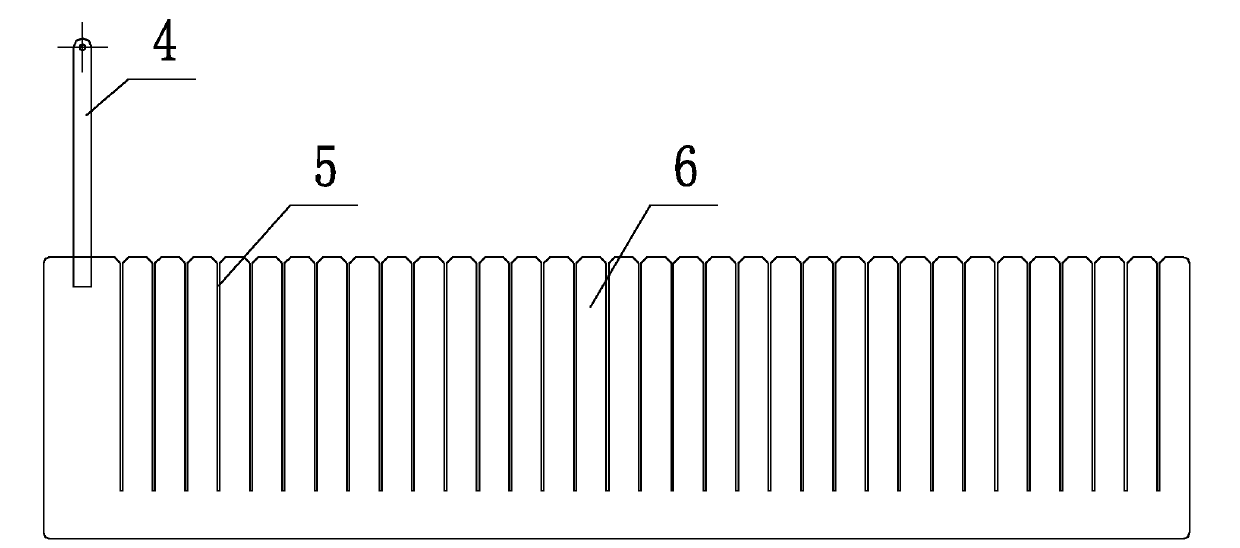

[0026] Refer to attached figure 1 , figure 2 and image 3 .

[0027] A transformer epoxy resin casting shielding cylinder is a casting shielding cylinder structure, and the casting shielding cylinder structure is a casting shielding inner insulation 1, a grounding shielding 2 and a casting shielding outer insulation 3 in sequence from the inside to the outside. The grounding shield 2 in the shielding cylinder is two semi-open copper foils 6 with winding structure. The lead-out metal strips 4 are welded on the copper foils 6. The openings 5 of the metal foils are 5mm, and the opening interval of the metal foils 6 is 70mm.

[0028] Concrete structure of the present embodiment and processing procedure thereof:

[0029] According to the design requirements and external dimensions of the transformer, the cast shielding tube mold and the grounding shielding copper foil 2 are made. The ground shield is welded by copper foil 6 and lead-out metal strip 4 . Wherein the copper fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com