Drill pipe connected through cooperation of taper pipe threads and spline sliding sleeve

A technology of spline sliding and mating connection, which is applied in the direction of drill pipe, drill pipe, casing, etc., can solve the problems of troublesome installation, small transmission torque, unstable operation, etc., and achieve tight connection, stable operation, firm and strengthened connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

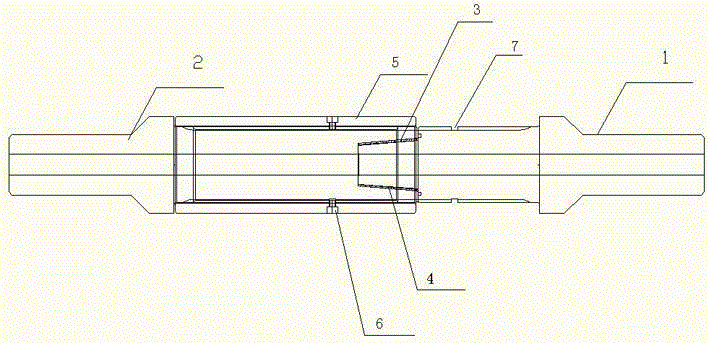

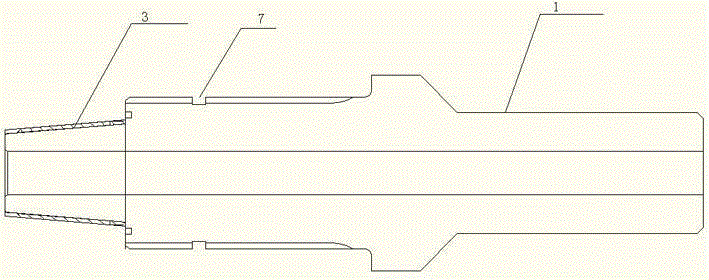

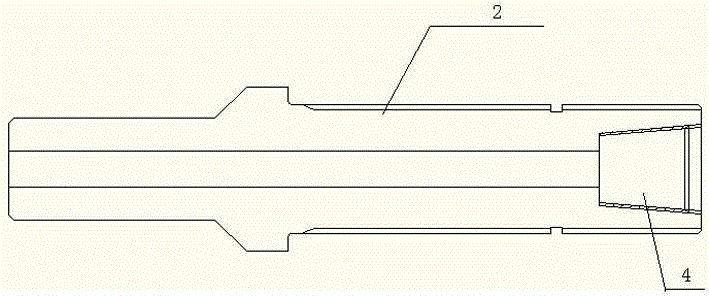

[0012] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

[0013] Such as Figure 1~4 As shown, the present invention adopts the drill pipe that the taper pipe thread and the splined sliding sleeve are matched and connected, including the upper drill pipe 1 and the lower drill pipe 2 connected to each other, and the connection between the upper drill pipe 1 and the lower drill pipe 2 is provided with a male Joint 3 and female joint 4, male joint 3 is located at the drill pipe joint of upper drill pipe 1, male joint 3 has external threads, female joint 4 is located at the drill pipe joint of lower drill pipe 2, female joint 4 has internal threads, male The cross-sections of the joint 3 and the female joint 4 are both tapered and arranged concentrically. The male joint 3 and the female joint 4 are connected by thread fit, and the concentrically arranged male joint 3 and the female joint 4 in the drill pipe a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com