Combined permanent magnet eddy current speed governor

A permanent magnet eddy current and governor technology, applied in electrical components, electromechanical devices, electromechanical transmission devices, etc., can solve the problems of bearing life impact, wiping disks, damaged equipment, etc., achieving high safety, long service life, reducing The effect of vibration interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

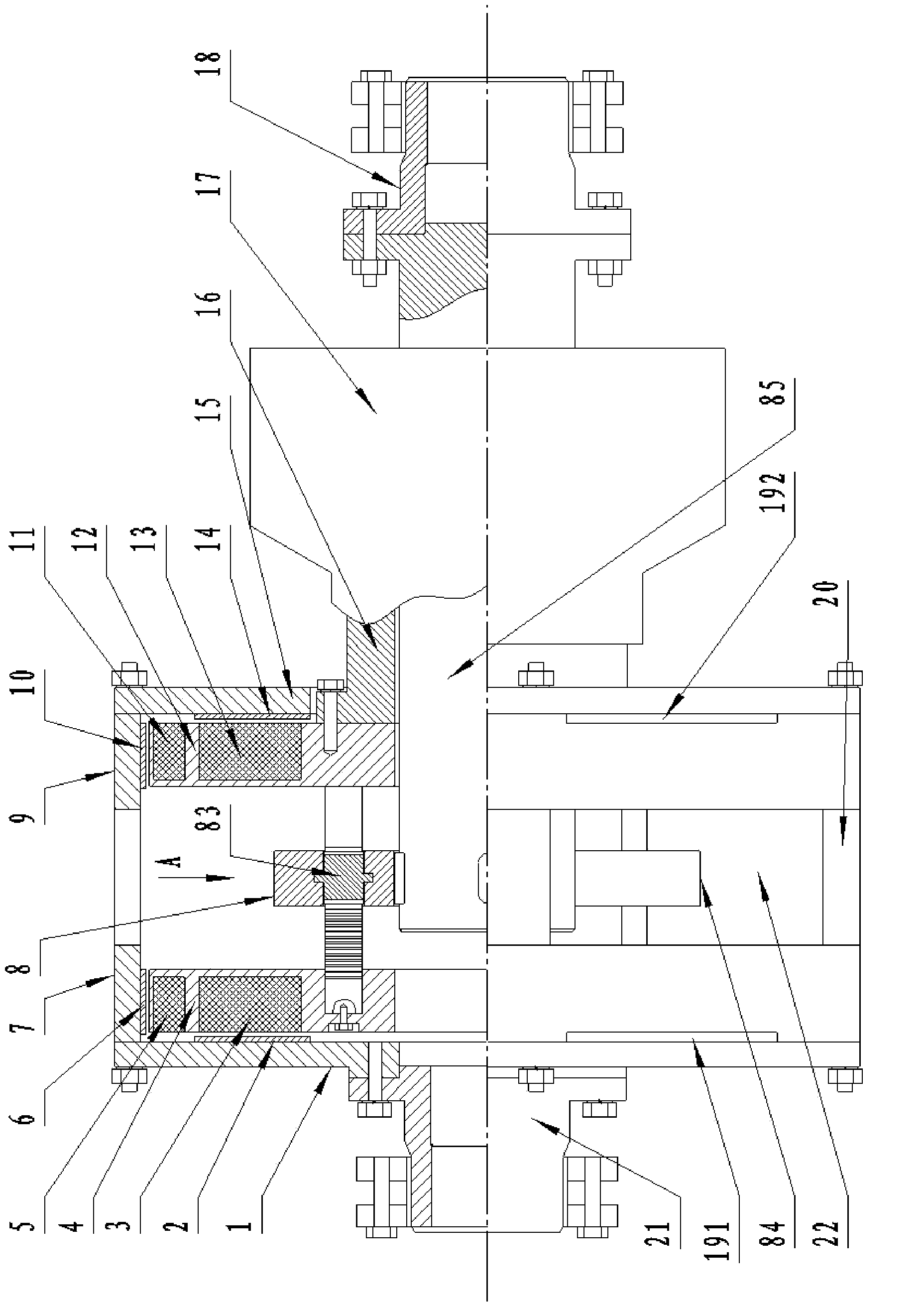

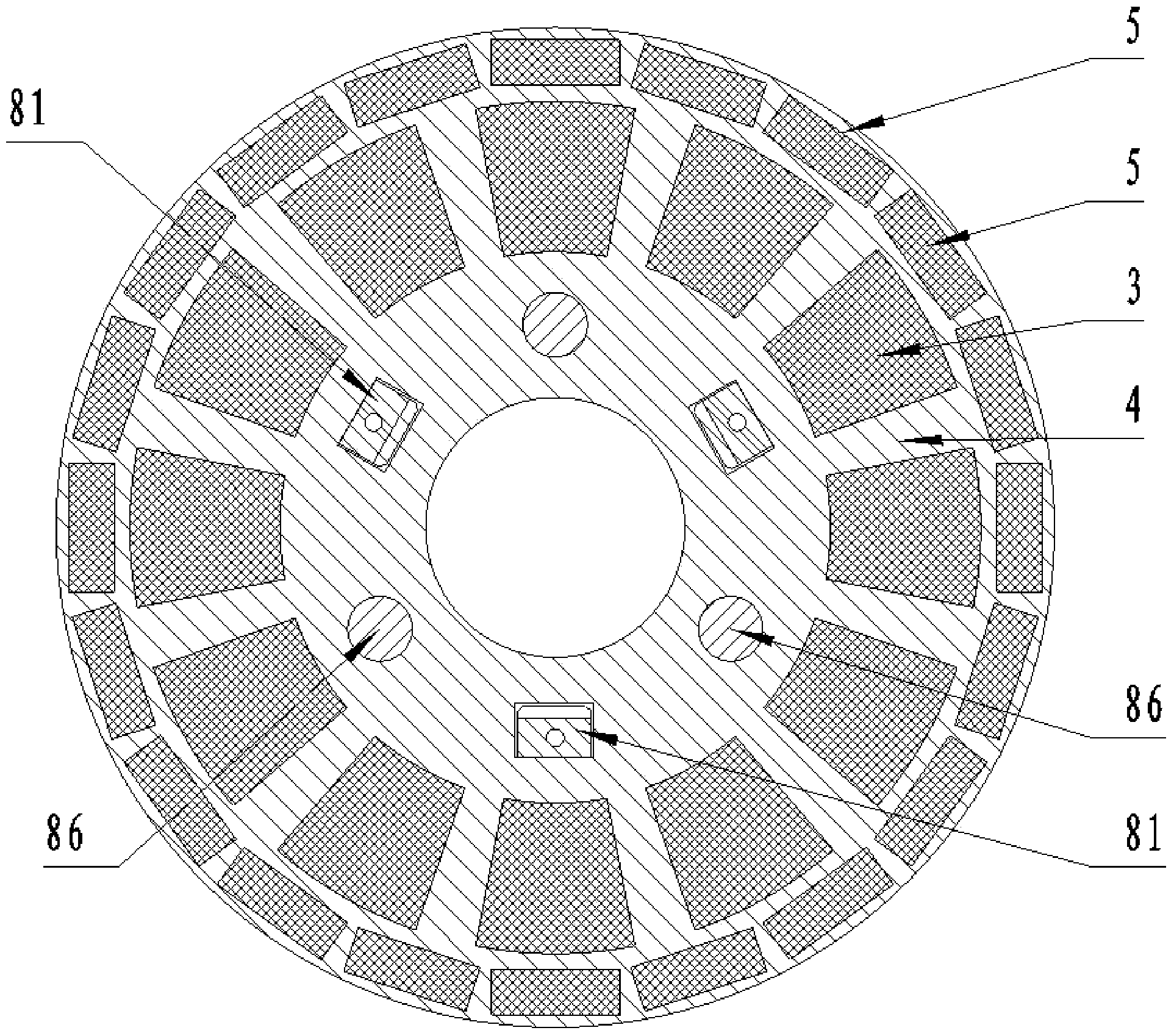

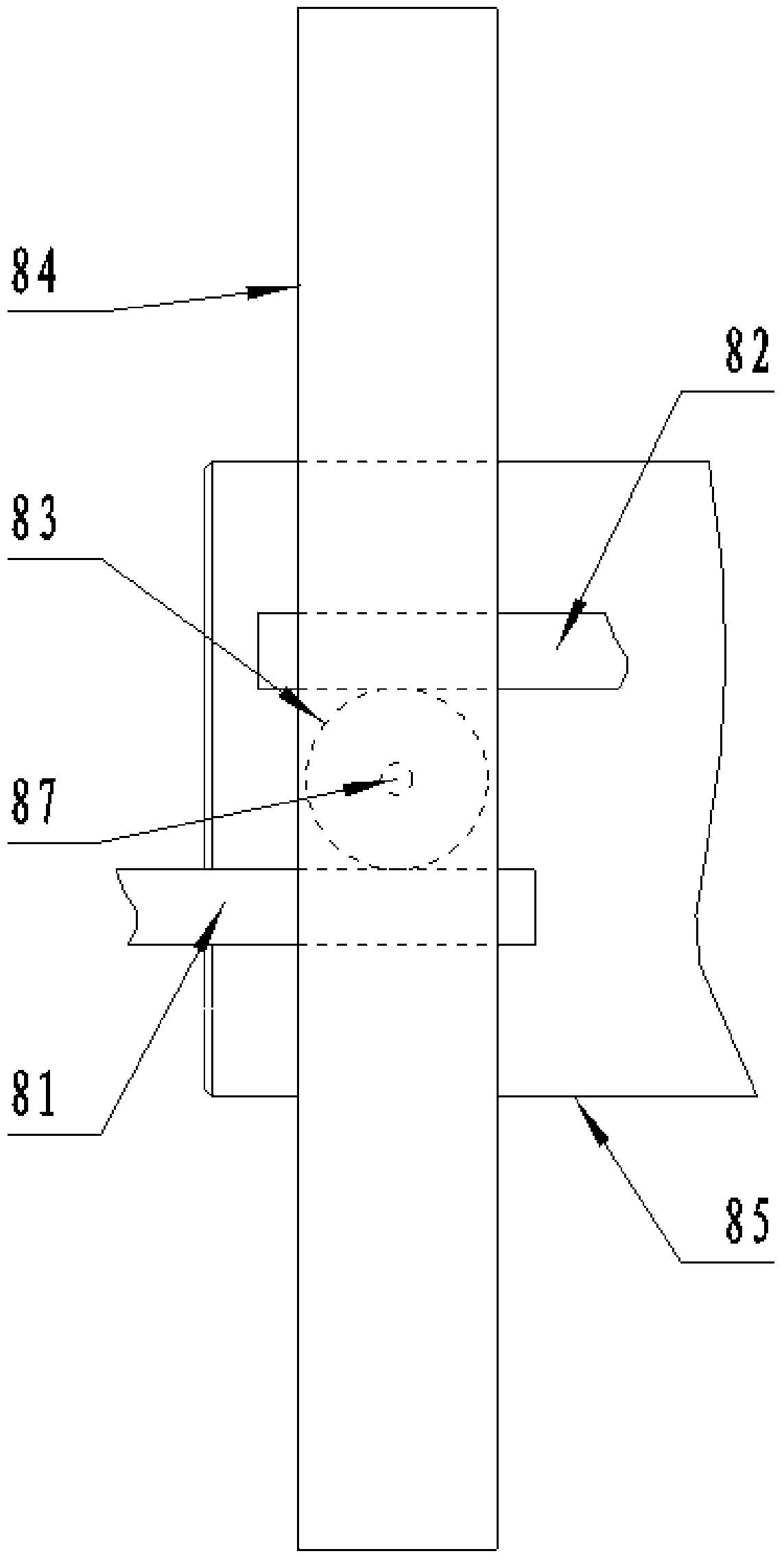

[0029] The composite permanent magnet eddy current governor of the present invention will be further described in detail below in conjunction with the accompanying drawings. A compound permanent magnet eddy current governor, comprising a conductor rotor and a permanent magnet rotor, the conductor rotor comprises a circumferential fixed sleeve, and the two ends of the circumferential fixed sleeve are respectively fixedly connected with a first conductor support disc and a second conductor support Disk, the inner surface of the first conductor supporting disk is provided with a first end surface conductor, the inner surface of the second conductor supporting disk is provided with a second end surface conductor, the inner surface of the circumferential fixed sleeve is provided with a radial conductor; the permanent magnet rotor It includes a first magnet mounting plate and a second magnet mounting plate parallel to each other, the edge area of the first magnet mounting plate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com