Planetary traction drive bearing type integral reduction hub

A traction transmission and planetary technology, applied in the field of wheel hub bearings, can solve the problems of planetary gear processing, difficult assembly, unfavorable bearing reducer structure, shortened axial dimension, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

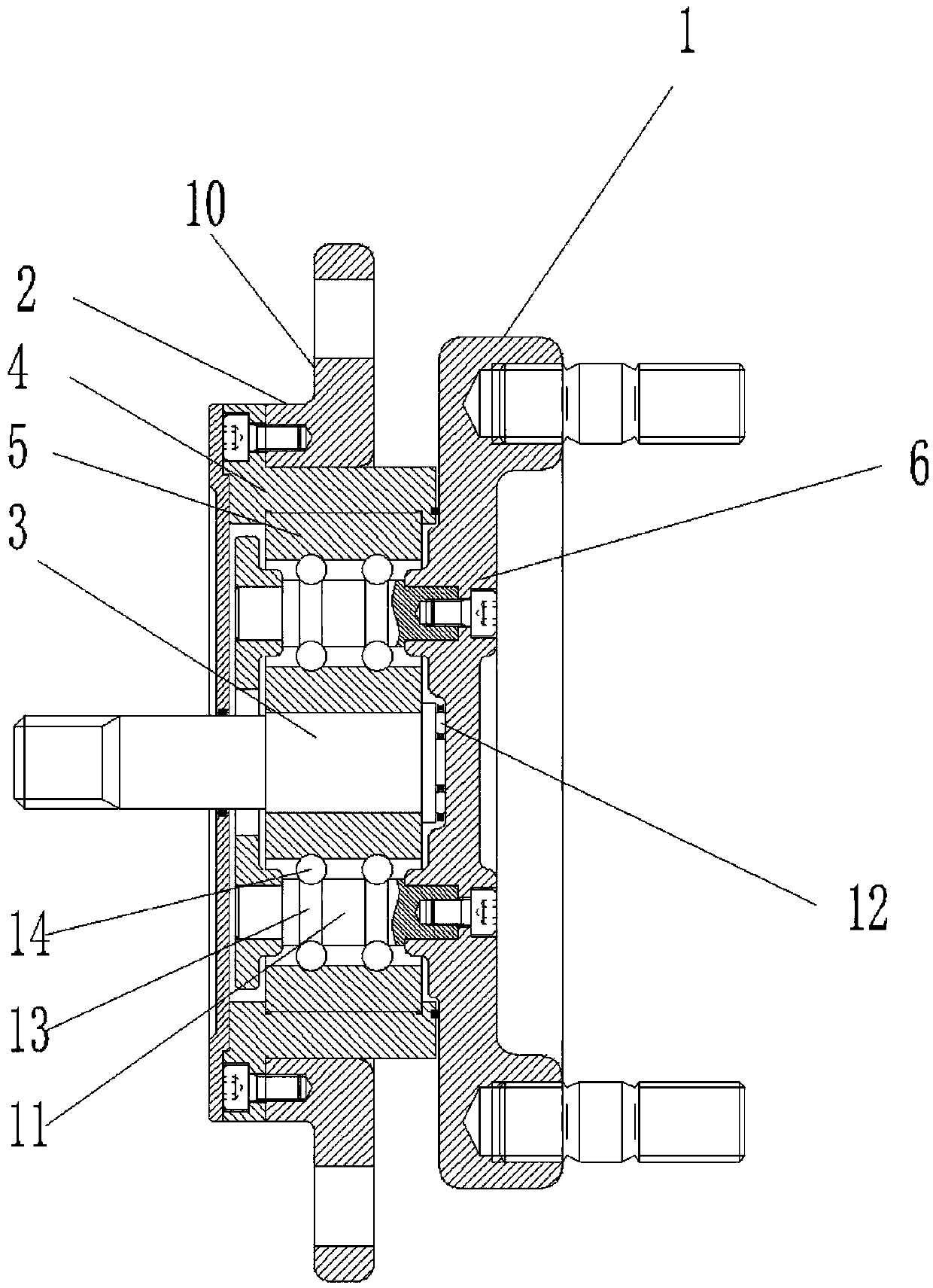

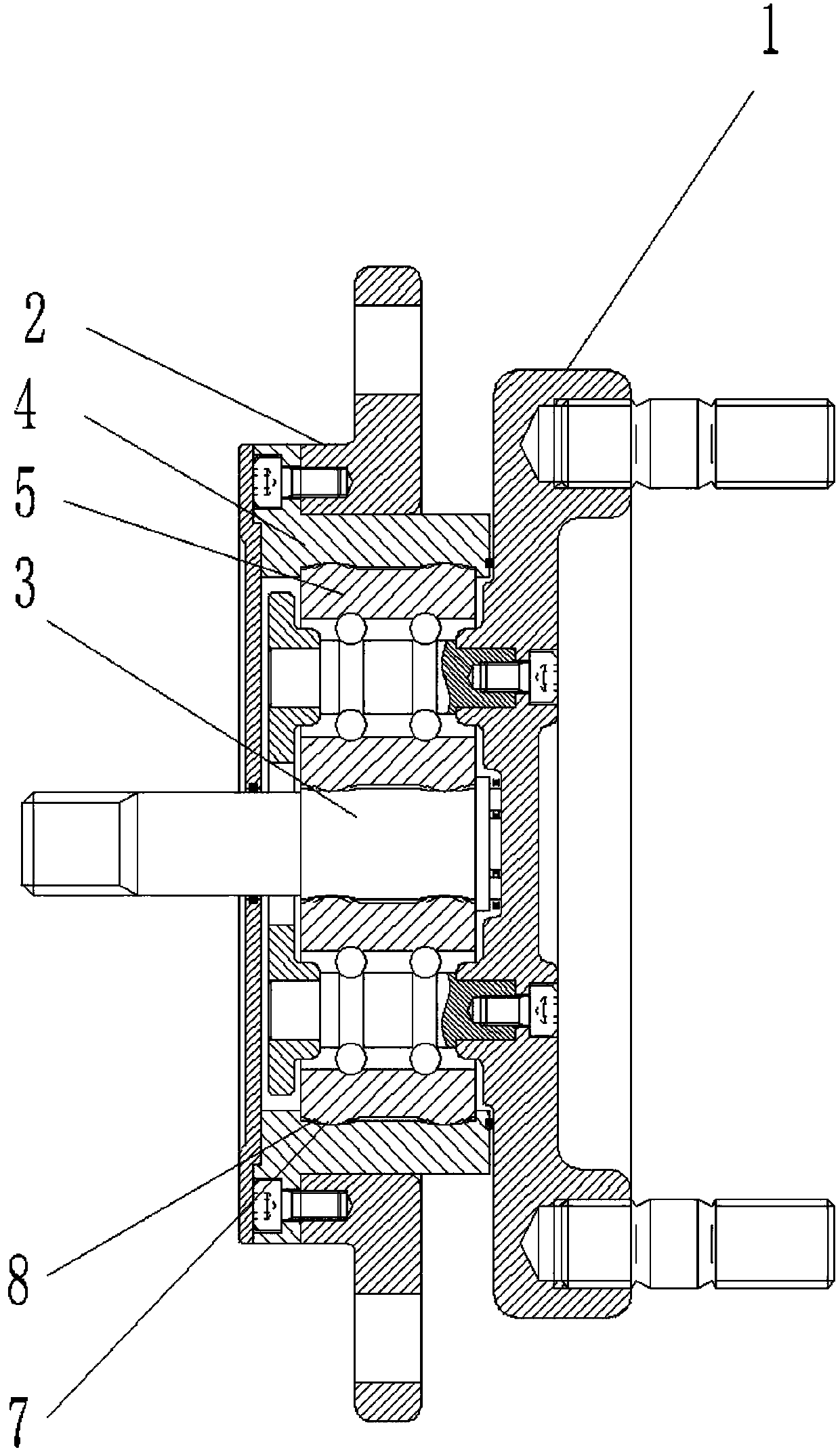

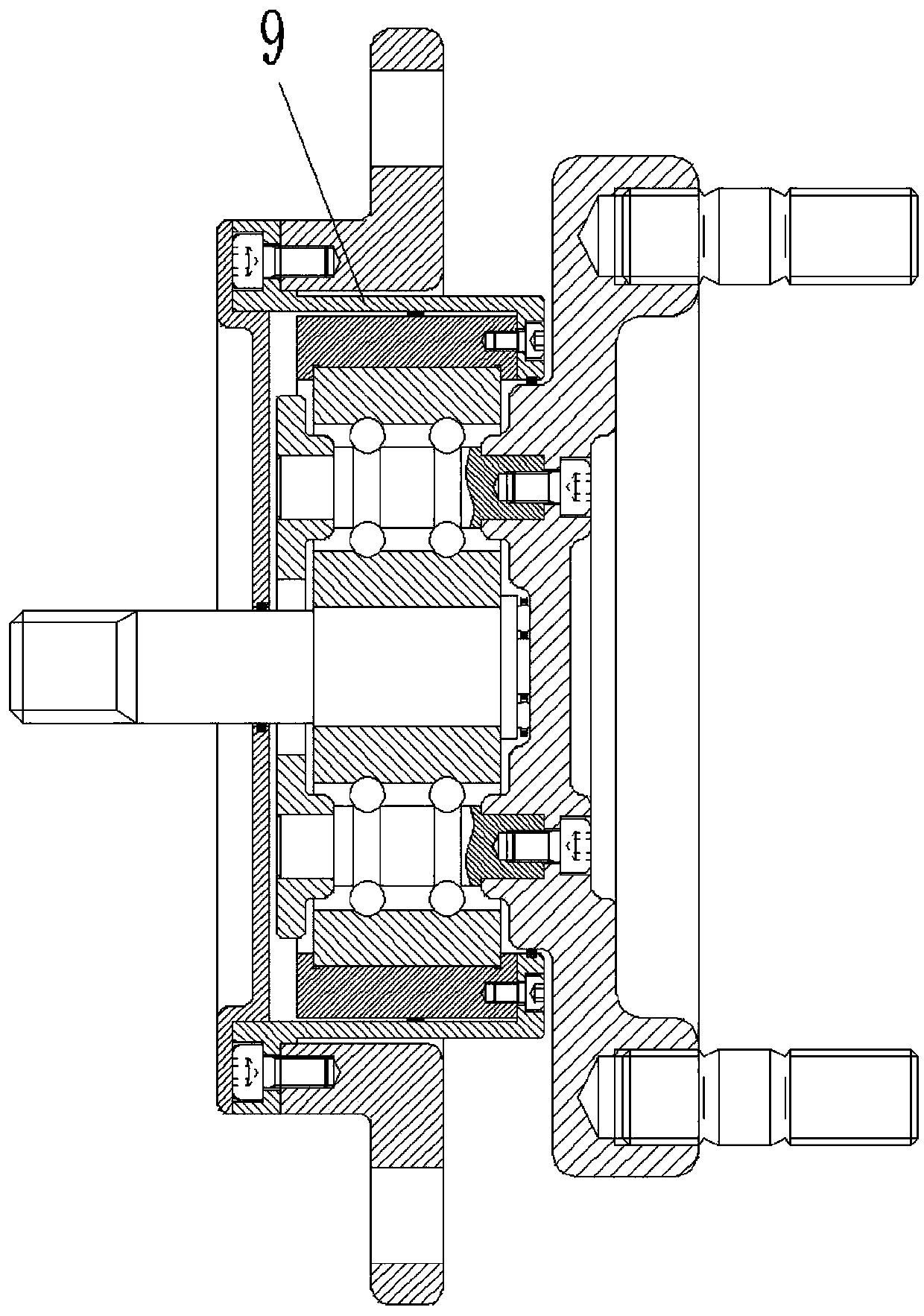

[0031] figure 1 It is a structural schematic diagram of the present invention using a planetary carrier as a power output end; figure 2 A schematic diagram of the structure of the planetary carrier used as the power output end for the present invention (the planetary rolling body is provided with an annular protrusion); image 3 It is a structural representation of the thin-walled metal cylinder used in the present invention; Figure 4 The structural representation of the thin-walled metal cylinder used in the present invention (the planetary rolling element is provided with an annular protrusion); Figure 5 It is a structural schematic diagram of the present invention using the outer ring of the reducer as the power output end; Figure 6 It is a schematic diagram of the structure of the present invention using the outer ring of the reducer as the power output end (the planetary rolling body is provided with an annular protrusion);

[0032]As shown in the figure: the plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com