Star wheel reducer

A technology of star gear reducer and reducer, applied in mechanical equipment, gear transmission, belt/chain/gear, etc., can solve the problem of not very high output torque, improve bearing capacity, reduce noise, and improve transmission torque Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

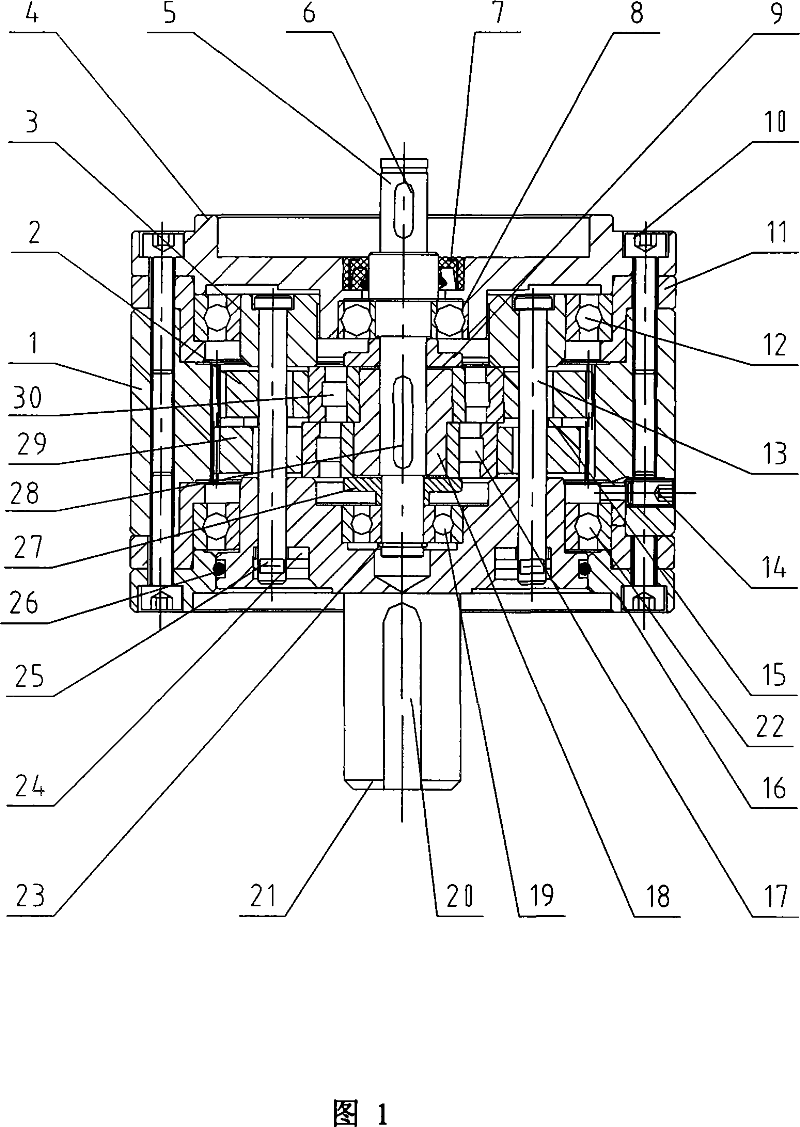

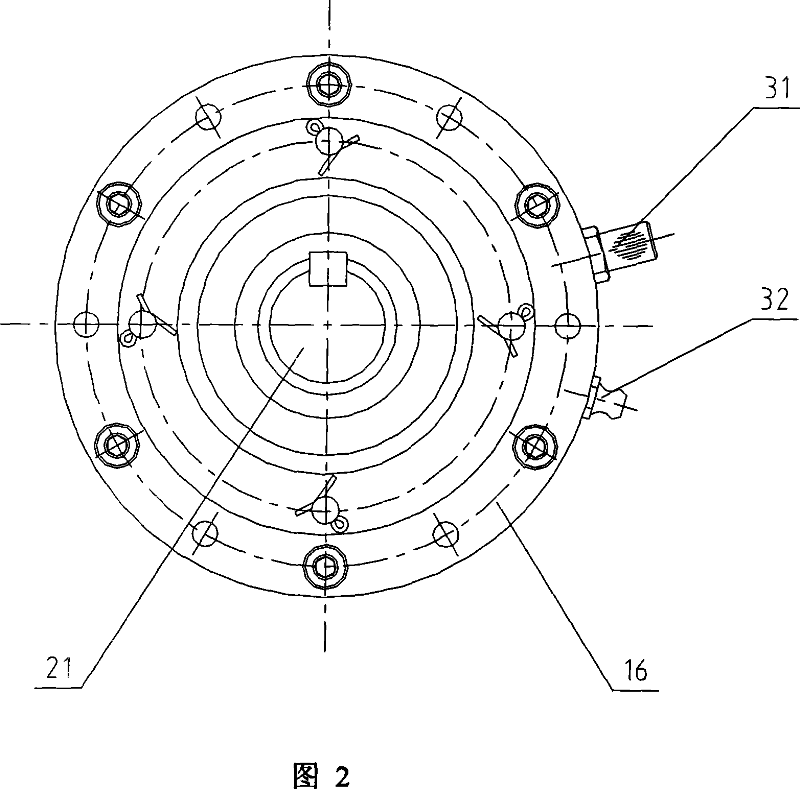

[0031] Refer to accompanying drawing 1.

[0032] Star gear reducer, the shell is equipped with input shaft, output shaft, gear, ring gear, the input shaft is equipped with eccentric sleeve 18, the input shaft 5 has double support bearings 8, 19, the input shaft is equipped with oil seal 7, retaining ring 9, Back-up ring 27 and back-up ring 23. The eccentric suit has two eccentric bearings 17,30, and the two eccentric bearings 17,30 are equipped with gears 2,29 respectively, the two gears 2,29 are provided with a spacer ring 15, the two gears 2,29 are externally connected to the ring gear 1, and the two gears 2, 29 is fixed on the load-sharing disc 3 and the shaft outlet shaft 21 by the connecting pin shaft 13, and the connecting pin shaft is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com