Sludge stock bin with rotary arch breaking mechanism

A driving mechanism and arch breaking technology, which is applied in the field of flat-bottomed silo, can solve the problems of large friction coefficient, affecting the stroke of the oil cylinder, easy to wear and so on, and achieve the effects of small friction, difficult to stack materials, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

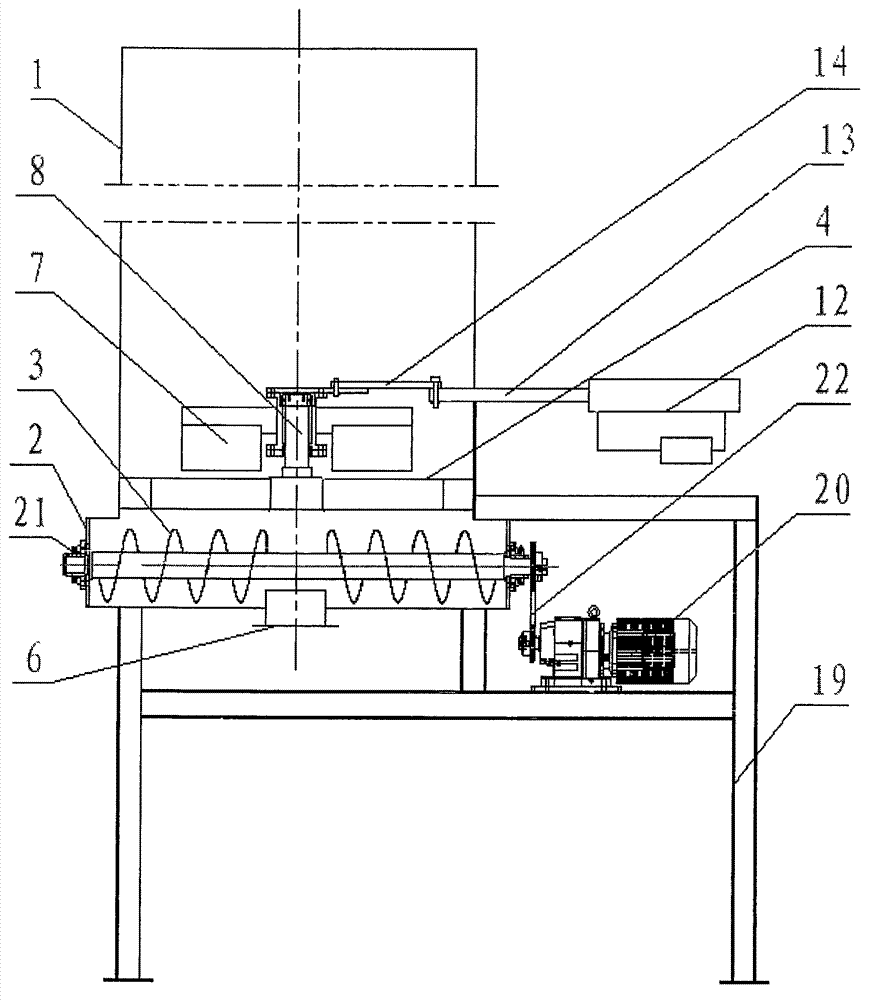

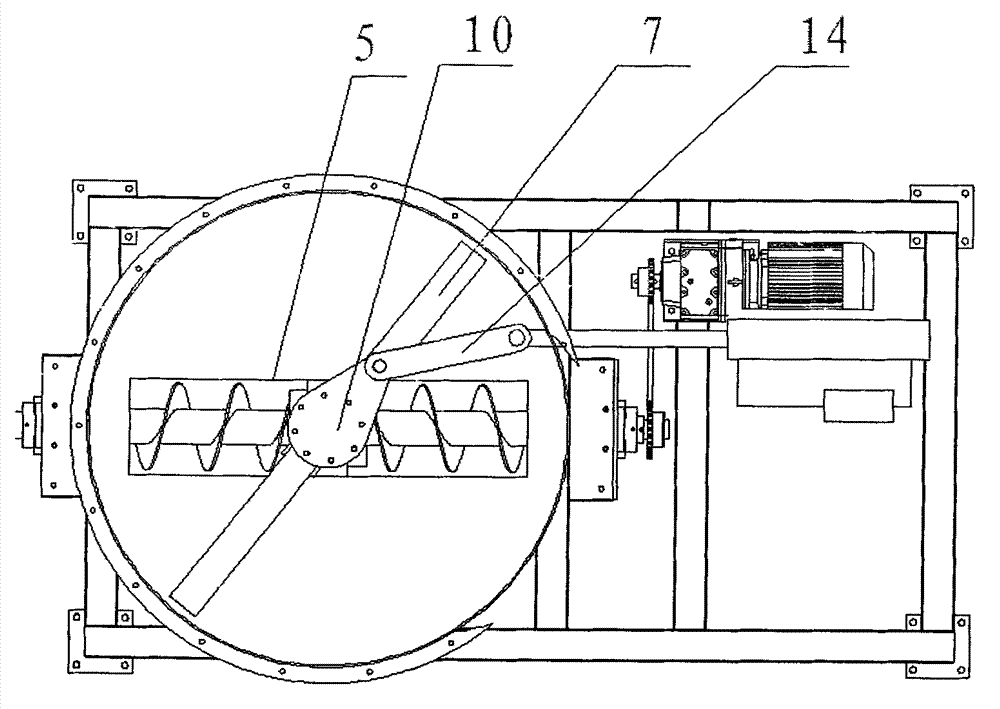

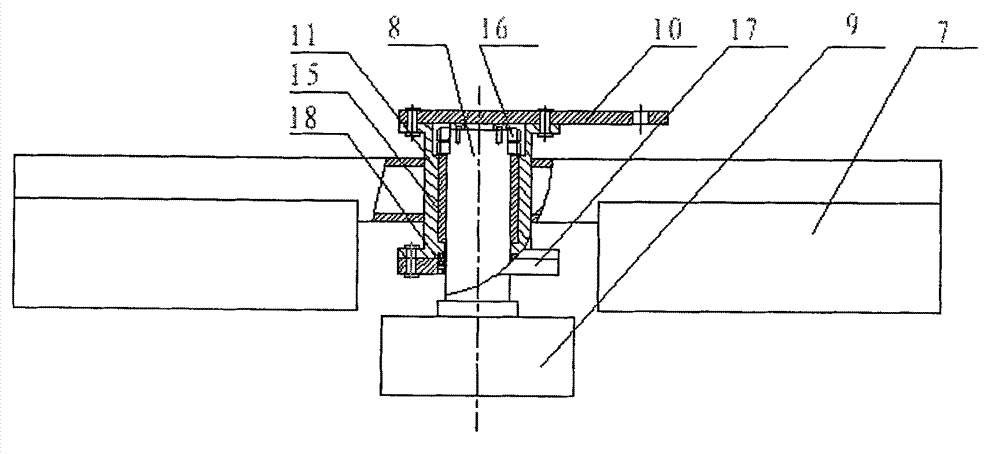

[0019] Such as figure 1 As shown, the sludge silo with a rotating arch-breaking mechanism of the present invention includes a silo body, a screw conveyor 1, an arch-breaking mechanism and an arch-breaking driving mechanism. The arch-breaking mechanism is placed in the silo body, and the The arch-breaking drive mechanism is connected with the arch-breaking mechanism, and the screw conveyor 3 is placed in the lower part of the silo body; the silo body includes an upper silo body 1 and a lower silo body 2, with Partition plate 4, described partition plate 4 is provided with strip-shaped feeding channel 5, and screw conveyor 3 is installed in the lower bin body 2, and is positioned at just below the strip-shaped feeding channel 5, and the bottom of lower bin body 2 is provided with There is a discharge port 6; the arch breaking mechanism is a rota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com