Counterbore countersink drill and machining process thereof

A countersinking and countersinking technology, which is applied in the direction of drilling/drilling equipment, metal processing equipment, boring machine/drilling machine parts, etc., can solve the problem of increasing the clamping force of drill bits and taps, coaxiality errors, hole drilling and countersinking Problems such as the complexity of the drill replacement process, to achieve the effect of increased clamping force, stable clamping state, and clear processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

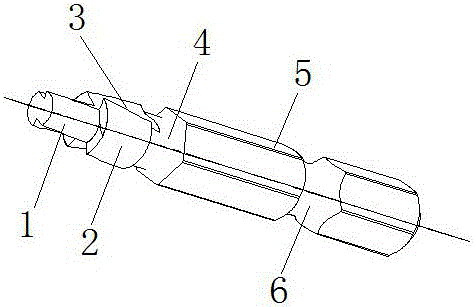

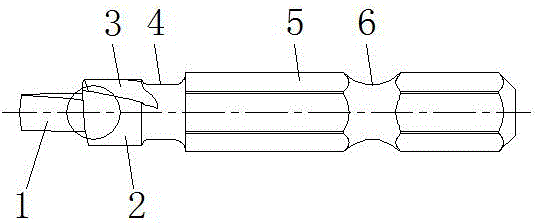

[0041] The present invention will be further described below in conjunction with accompanying drawing:

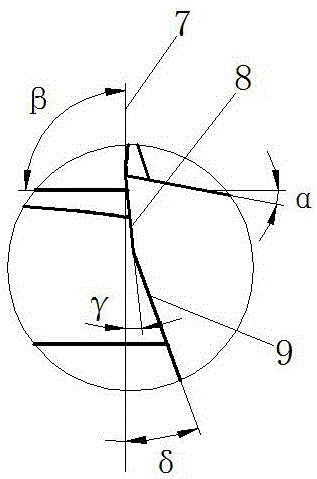

[0042] Such as Figure 1-5 As shown, a countersinking countersinking drill is composed of a guide post 1, a countersinking cutting post 2 and a drill shank 5, a tool groove 4 is provided between the countersinking cutting post 2 and the drill shank 5, and the guide post 1 and the surface of the counterbore cutting column 2 are provided with a chip removal groove 3 connected with a thread lead angle α, and the chip removal groove 3 with a thread lead angle α starts from the head of the guide post 1 and ends at the tool groove In 4, the middle part of the drill shank 5 is provided with a quick connection groove 6, the head of the guide post 1 is provided with the opening angle of the guide post, and the end face of the head of the counterbore cutting post 2 is provided with a first cutting edge formed by a first cutting edge 8. plane and the second cutting plane formed by th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com