Kitchen knife floating grabbing and clamping device

A clamping device and kitchen knife technology, applied in chucks, manipulators, manufacturing tools, etc., can solve problems such as uneven quality control, poor positioning of kitchen knives, and increased difficulty in grinding and polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

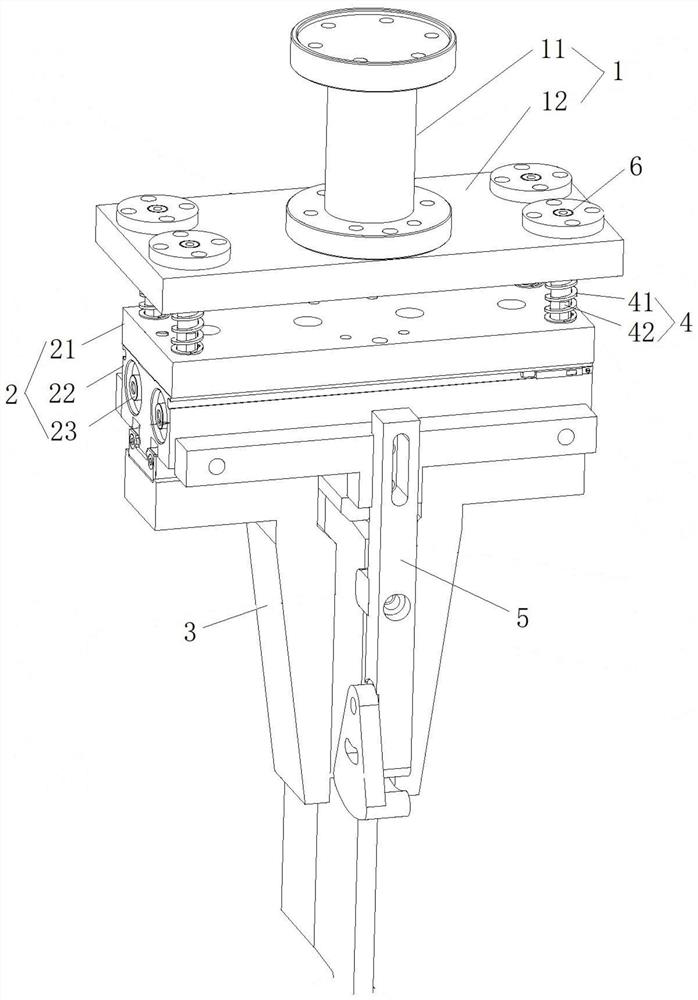

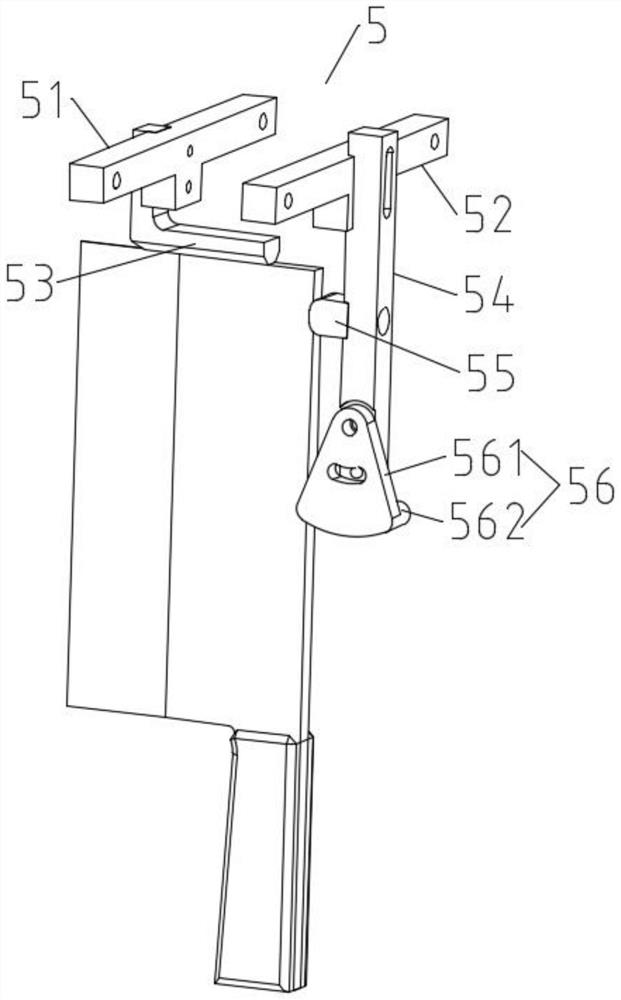

[0036] Such as figure 1 , 2 As shown, the core of the present invention is to provide a kind of kitchen knife floating grasping and clamping device, which is used to clamp and fix the kitchen knife to be processed, including: a fixed end 1 for connecting with the end of the robot; a clamping part 2, a clamping part 2 A plurality of floating parts 4 are arranged between the fixed end 1, and the side of the clamping part 2 away from the fixed end 1 is provided with two clamping plates 3 for grasping and clamping the kitchen knife to be processed. The plate 3 is connected by transmission; it is arranged between the two clamping plates 3 and is used for positioning the edge piece 5 of the kitchen knife to be processed, and the edge piece 5 is fixedly connected with the clamping piece 2 .

[0037] It should be noted that the two clamping plates 3 are set opposite to each other, and guide rails are provided on the lower side of the clamping piece. The plates 3 are close to or far ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com