Belt for yarn twisting

A technology of twisting and endless belts, used in transmission belts, belts/chains/gears, continuous winding spinning machines, etc., can solve the problems of shortened life, belt wear, strong elasticity, etc., and achieve a stable clamping state , The effect of reducing partial wear and eliminating partial wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

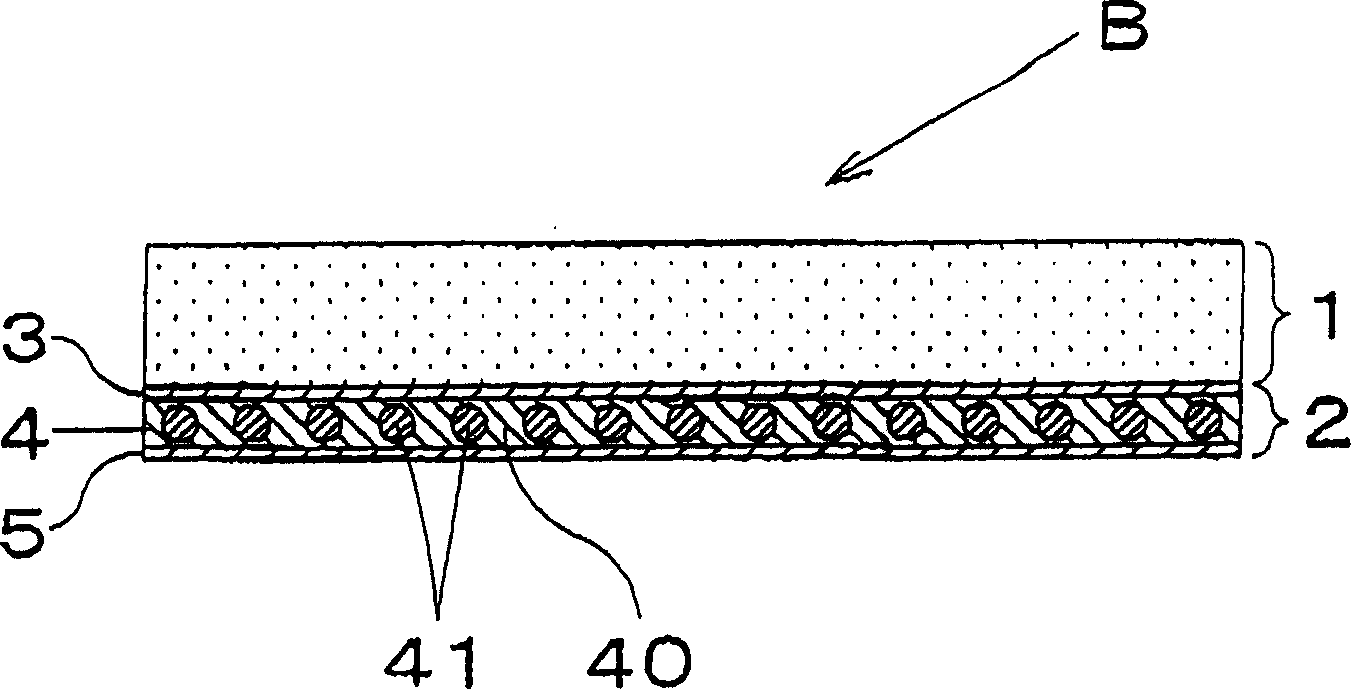

[0044] According to the above-mentioned manufacturing process, a figure 1 Tape B for twisted yarn with the cross-sectional structure shown. The respective constituent parts used are as follows.

[0045] (1) Surface rubber layer 1: H-NBR

[0046] (2) Intermediate weaving 3 (seamless weaving):

[0047] (with circumferential direction) 150 denier nylon, nylon-wool thread,

[0048] (Tape width direction) 150 denier polyethylene terephthalate filament

[0049] (3) Core layer 4:

[0050] (Core 41) 500-denier polyethylene terephthalate wire (56 wires per inch in the tape width direction)

[0051] (4) Outer fabric 5: 150 denier polyethylene terephthalate filament

[0052] The obtained tape B for twisted yarns was cut into a width of 8 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com