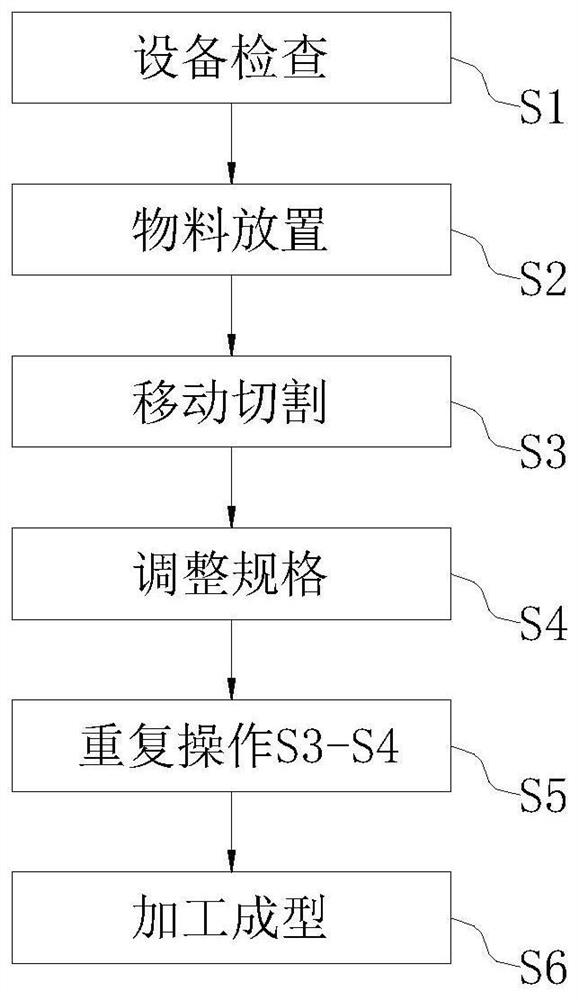

Preparation process of light foam concrete blocks

A concrete block and foam concrete technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of small working range, high labor intensity, and insufficient clamping stability, so as to improve uniformity and precision, reduce labor intensity, The effect of reducing the degree of intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

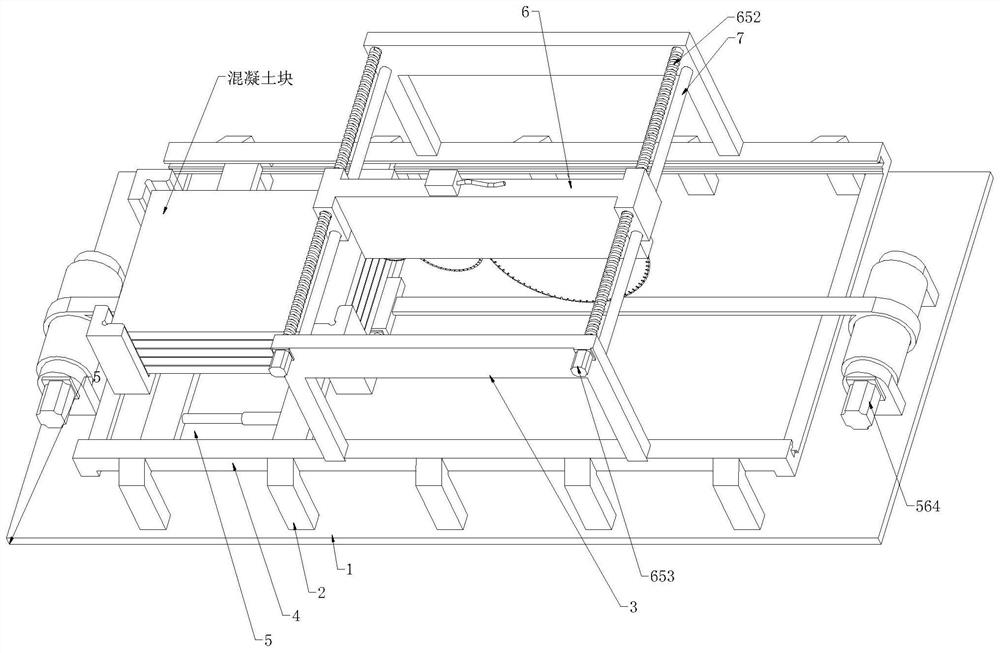

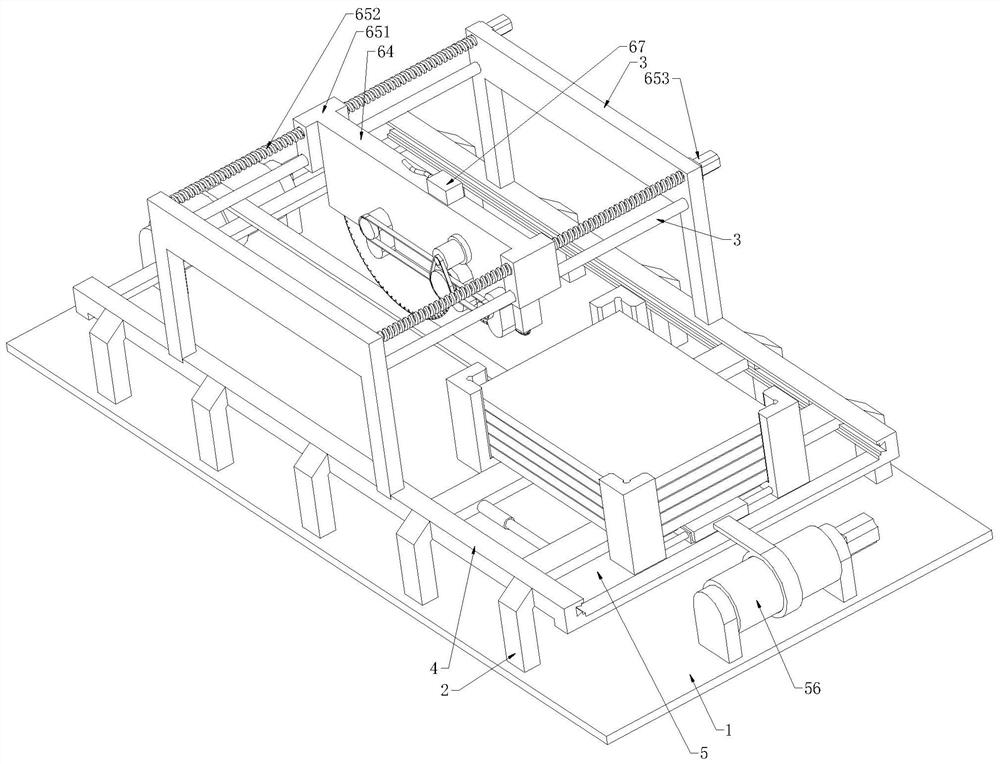

[0036] The following is attached Figure 1-8 The present invention is described in further detail.

[0037] It is a light foam concrete block preparation process of the present invention, which uses a foam concrete block processing equipment, which includes a bottom plate 1, a support frame 2, a mounting frame 3, a guide rail block 4, and a mobile clamping device 5 And the cutting device 6, the base plate 1 is arranged on the ground, and several support frames 2 are symmetrically arranged on the base plate 1 in two groups. One side of the base plate 1 is used for the installation of the cutting device 6; in this embodiment, the guide rail block 4 includes a guide rail and a connecting block, and the two guide rails are symmetrically arranged on the end of the support frame 2 away from the base plate 1, and are fixedly connected by the connecting block Setting, the two ends of the moving block 53 are limited and slide on the side where the guide rail blocks 4 on both sides are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com