High-machining-precision integrated type hole drilling tapping tool and manufacturing method thereof

A tapping tool and machining accuracy technology, applied in drilling tool accessories, manufacturing tools, thread cutting tools, etc., can solve the problems of complex procedures and poor machining accuracy, and achieve a clear working principle, stable clamping state, and high machining. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings:

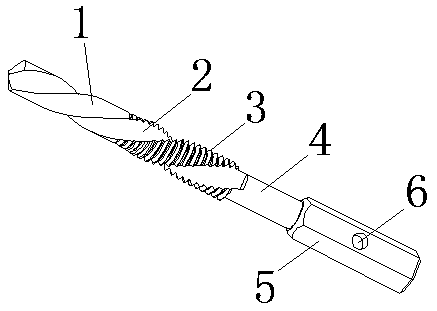

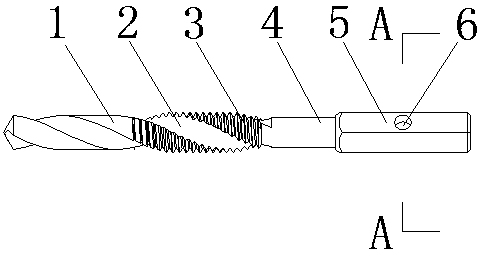

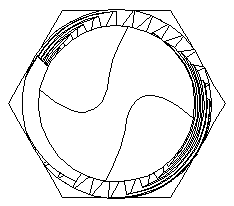

[0043] like Figure 1-4 As shown in the figure, an integrated drilling and tapping tool with high machining accuracy is composed of a working part and a shank 5; the working part is composed of a drill part 1, a tap part 3 and a chip flute 2 , the drill bit part 1 is at the front end of the integrated drilling and tapping tool, the tap part 3 is in the middle of the integrated drilling and tapping tool and is continuously connected with the drill bit part 1, and the chip flute 2 is continuously arranged in the drill bit part 1 and the tap part On the surface of 3, between the tap part 3 and the shank 5, there is a section to let the knife groove 4, the shank 5 is in the shape of an upright hexagonal prism, and three positioning holes 6 are opened on the prism side of the shank 5, and the positioning holes 6 are in the upright hexagonal prism. The surfaces are distribu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com