Shipbuilding method

A construction method and ship technology, applied in ship construction, ship parts, ships, etc., can solve problems such as ineffective utilization of resources and waste of dock space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

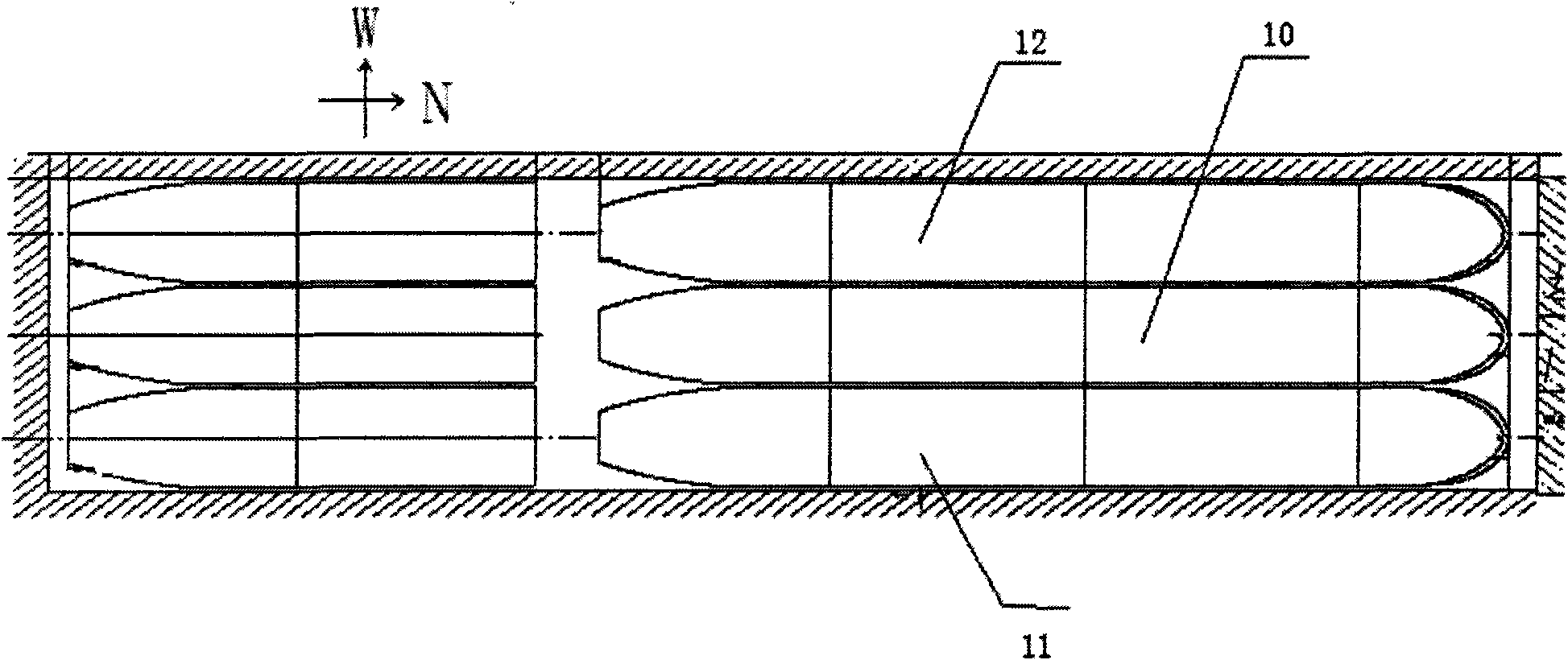

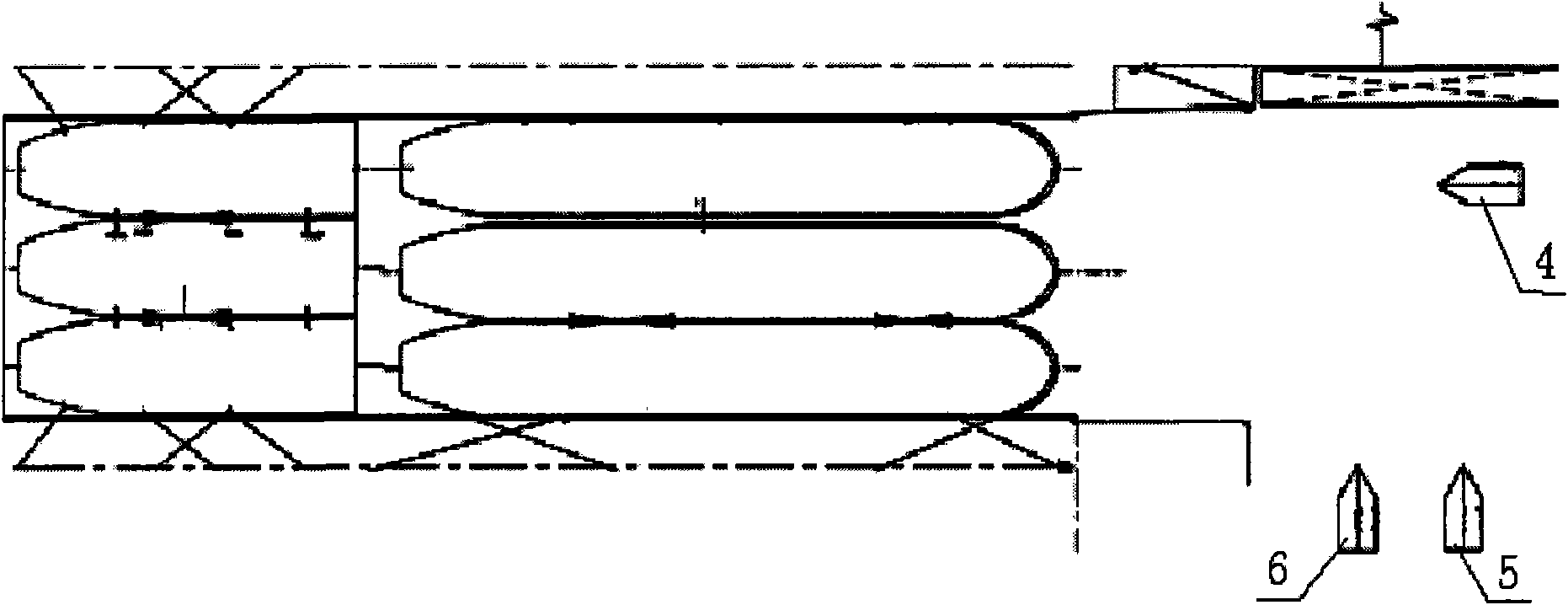

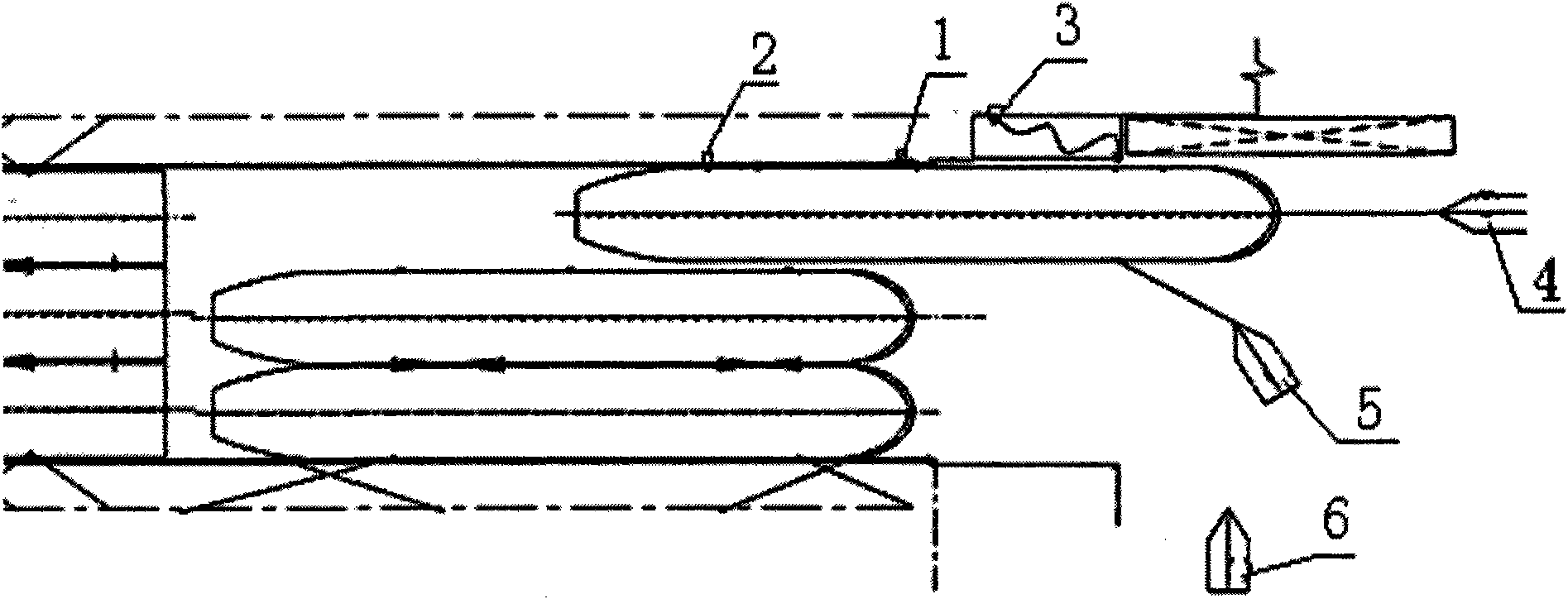

[0096] A kind of ship building method of present embodiment, technical route

[0097] 1. Equipped with technical route

[0098] When the distance between ships is 1.2 meters, determine the precision control during the loading process and how to effectively expand the construction surface.

[0099] 1.1 Improve the production quality of sections, increase the magnitude of control, and implement no-surplus production and no-surplus loading for planar sections with small hull spacing.

[0100] 1.2 Improve the precision control during hoisting, especially for the special and difficult sections of some hoisting parts, research and formulate the hoisting plan, and implement it accurately.

[0101] 1.3 Use methods such as hanging blue construction to solve the problem of unfavorable expansion of the working face when the spacing is small.

[0102] 2. Coating technology route

[0103] In the "3+3 ship building method", ship painting is required to be applied at small intervals.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com