Thermally conductive slurry as well as preparation method and application thereof

A slurry and photothermal technology, applied in the direction of additive processing, etc., to achieve the effect of increased applicability, good stability, and reduced functional differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

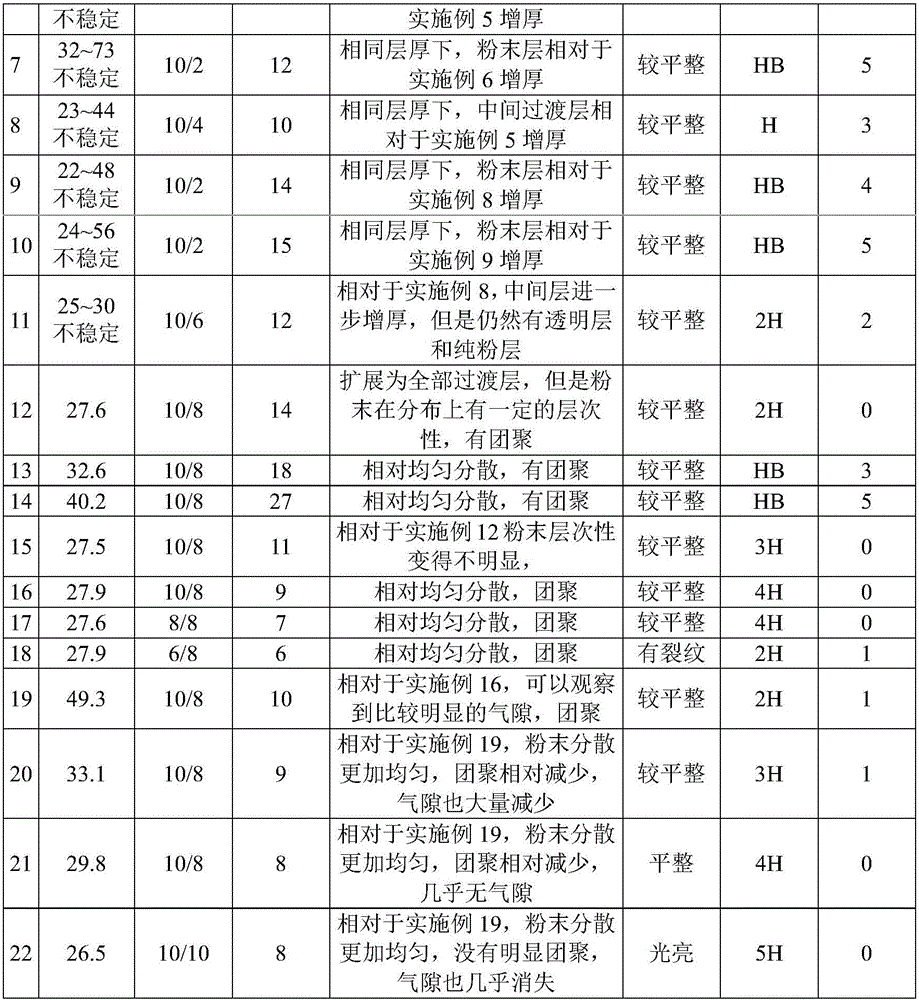

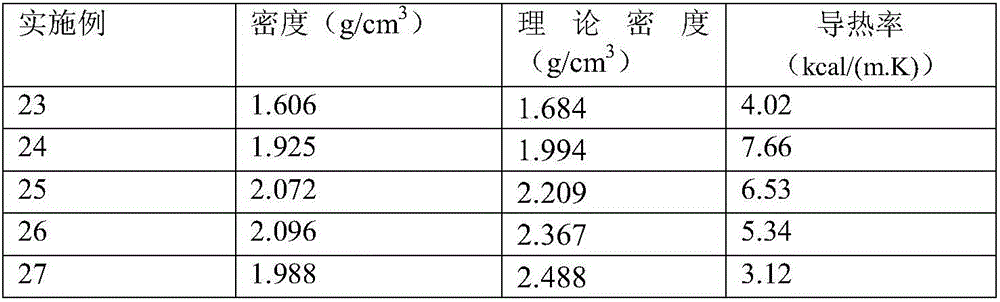

Examples

Embodiment 1

[0025] Add 5g of photothermal dual curing resin (epoxy acrylic resin) to 10g of diluent (absolute ethanol: viscosity 1.06mPa s, boiling point 78.4°C, surface tension 22.32mN / m, volatile), stir well to dissolve completely . Add 4g of alumina powder to the solution, stir thoroughly, and ultrasonically crush for 5 minutes to fully wet and disperse the alumina powder, use the mass conservation method to replenish the diluent lost due to volatilization, and stir evenly to obtain 19g of the product thermally conductive slurry . The performance tests are shown in Table 1.

Embodiment 2

[0027] Add 5g of photothermal dual-curing resin (epoxy acrylic resin) to 15g of diluent (absolute ethanol: viscosity 1.06mPa s, boiling point 78.4°C, surface tension 22.32mN / m, volatile), stir well to dissolve completely . Add 4g of alumina powder to the solution, stir thoroughly, and ultrasonically crush for 5 minutes to fully wet and disperse the alumina powder, use the mass conservation method to replenish the diluent lost due to volatilization, and stir evenly to obtain 24g of the product thermally conductive slurry . The performance tests are shown in Table 1.

Embodiment 3

[0029]Add 5g of photothermal dual-curing resin (epoxy acrylic resin) to 10g of diluent (propylene glycol methyl ether acetate: viscosity 1.10mPa·s, boiling point 146°C, surface tension 28.9mN / m, relatively volatile), and fully stir to dissolve completely. Add 4g of alumina powder to the solution, stir thoroughly, and ultrasonically crush for 5 minutes to fully wet and disperse the alumina powder, use the mass conservation method to replenish the diluent lost due to volatilization, and stir evenly to obtain 19g of the product thermally conductive slurry . The performance tests are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com