Liquid filling accuracy control method for liquid filling quantity smaller than minimum measured quantity

A precision control and measurable technology, applied in liquid distribution, liquid distribution, conveying or transfer devices, special distribution devices, etc., can solve problems such as losses, many motorcycle refueling operations, and uncontrollable minimum filling volume accuracy, and achieve Precision control, effective precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

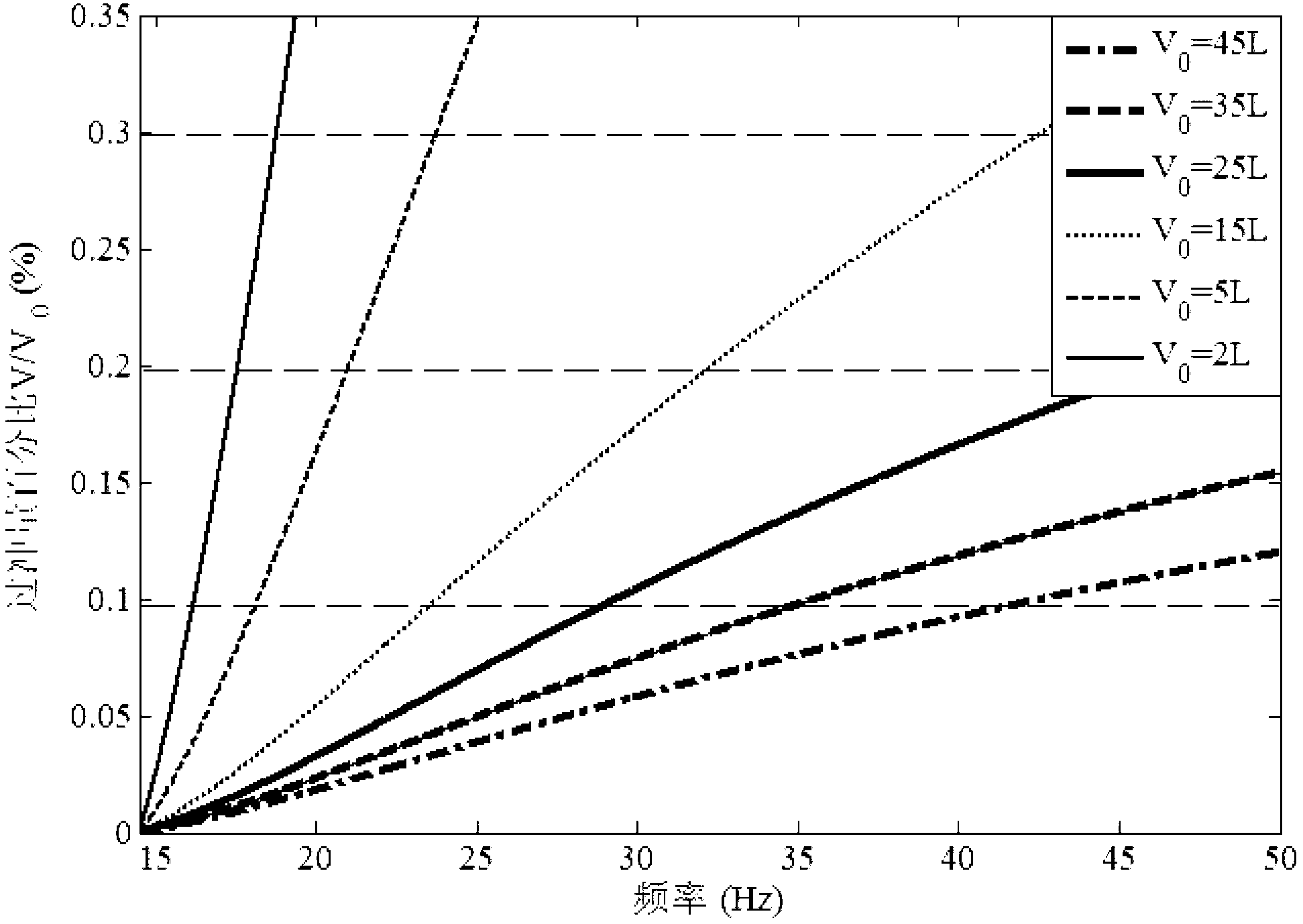

[0028] In this embodiment, the liquid filling machine is used as the fuel filling machine, and the fuel filling amount V is preset 0 2L (the fuel filling volume is lower than the minimum measured value of the tanker), the set overshoot percentage As an example, the following will be explained.

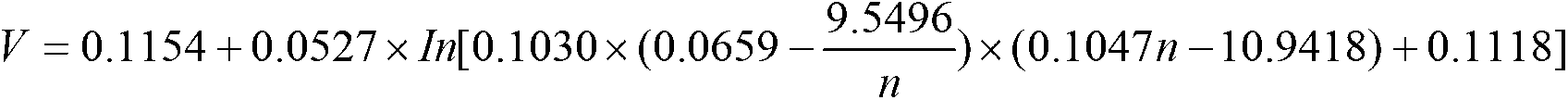

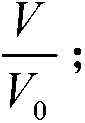

[0029] The method of the present invention draws the relationship curve between the percentage of overshoot of the dispenser and the buffer frequency of the variable frequency motor in the variable frequency hydraulic control system of the dispenser, and realizes the accuracy control of the dispenser in quantitative refueling according to the relationship curve; wherein, the percentage of overshoot is Overshoot amount V and preset fuel amount V 0 The ratio of the overshoot V is calculated by the following formula:

[0030] V = 0.1154 + 0.0527 X In [ 0.1030 X ( 0.0659 - 9.5496 n ) X ( 0.1047 n - 10.9418 ) + 0.1118 ]

[0031] Among ...

Embodiment 2

[0042] The control method of the present invention is also suitable for effective control of the accuracy of the fuel filling machine higher than the minimum measured fuel dispenser. In this embodiment, the liquid filling machine is used as the fuel dispenser, and the fuel filling volume V is preset 0 45L (the fuel filling volume is higher than the minimum measured value of the tanker), the set overshoot percentage As an example, the following will be explained.

[0043] The difference between this embodiment and the first embodiment is only the fuel dispenser parameter preset fueling volume V 0 The other parts are consistent with the first embodiment.

[0044] Such as figure 1 As shown, corresponding to the pre-set amount of 45L fueling volume (the fueling volume is higher than the minimum measured value of the fueling machine), the present invention implements the accuracy control of the fueling machine in quantitative fueling according to the relationship curve and includes the ...

Embodiment 3

[0051] The control method of the present invention is also applicable to other liquid filling fields. In this embodiment, the liquid filling machine is a liquid beverage filling machine as an example to describe the following.

[0052] In the actual beverage filling, the method of the present invention can select different buffer frequencies for different preset liquid beverage filling quantities, and can control the percentage of overshoot within a smaller error range (for example, 0.1%) to achieve Effective control of the accuracy of the beverage filling machine that is lower than the minimum to be measured in the quantitative beverage filling.

[0053] According to the relationship curve, the present invention realizes the accuracy control of the liquid beverage filling machine in the quantitative beverage filling process, including the following steps:

[0054] The first step is to store the drawn overshoot percentage of the liquid beverage filling machine and the buffer frequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com