Three-frequency frequency reconfigurable antenna for coplanar waveguide feed

A technology of coplanar waveguide and reconstructed antenna, which is applied to antennas, antenna grounding devices, and devices that make antennas work in different frequency bands at the same time. Effects of reduced influence of characteristics, good impedance matching, and high availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

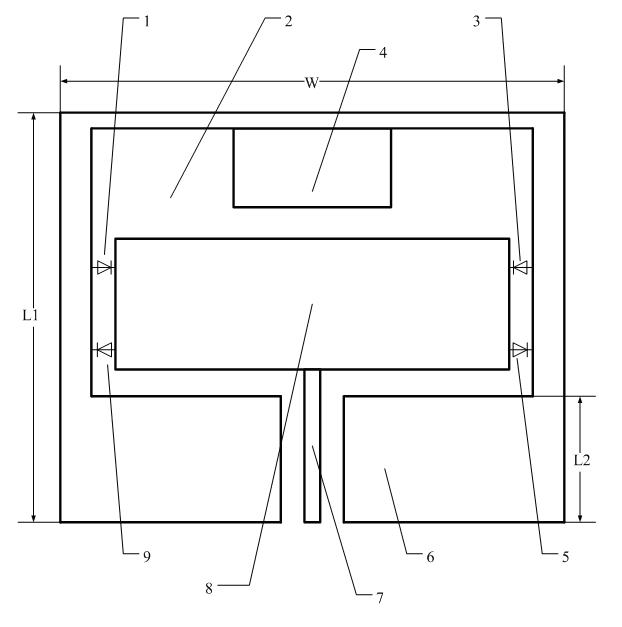

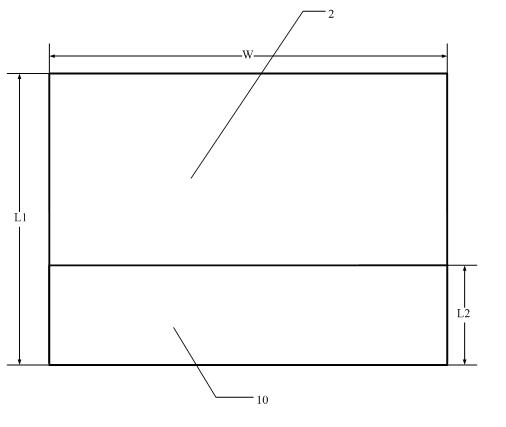

[0034] Embodiment one: see figure 1 , the coplanar waveguide-fed tri-frequency frequency reconfigurable antenna includes an upper metal microstrip, a middle dielectric substrate 2 and a lower back floor 10, the metal microstrip includes a radiation patch 8, and a coplanar waveguide floor 6. Coplanar waveguide feeder 7, matching branch 4 and four PIN diodes 1, 3, 5, 9, the coplanar waveguide floor 6 surrounds the radiation patch 8, and the coplanar waveguide floor 6 and the radiation patch are separated by Four PIN diodes 1, 3, 5, and 9 are connected, the coplanar waveguide feeder 7 is located at the central opening under the coplanar waveguide floor 6 and is integrated with the radiation patch 8, and the matching branch 4 is integrated with the upper part of the coplanar waveguide floor 6 The back floor 10 is a metal coating located on the back of the dielectric substrate 2 corresponding to the lower part of the coplanar waveguide floor 6 and below the coplanar waveguide feede...

Embodiment 2

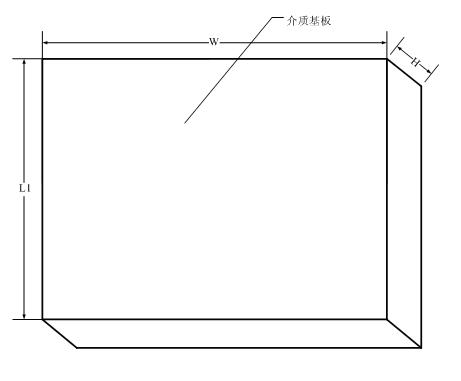

[0035] Embodiment two: see figure 1 and figure 2 , this embodiment is basically the same as Embodiment 1, and the special features are as follows: the size of the dielectric substrate (2) is 95mm*110mm*0.8mm, the upper layer and the lower layer are metal coating, and the material is copper.

Embodiment 3

[0036] Embodiment 3: The tri-frequency frequency reconfigurable antenna fed by the coplanar waveguide is divided into upper, middle and lower layers. upper as figure 1 As shown, it is composed of metal microstrip antenna and RF PIN diodes 1, 3, 5, and 9; the lower layer is as figure 2 Consists of metal back floor as shown; intermediate layer as image 3 Shown is the dielectric substrate 2 used in this embodiment, with a thickness H.

[0037]This antenna has a left-right symmetrical structure. The coplanar waveguide floor 6 and the coplanar waveguide feeder 7 constitute the feeding form of the coplanar waveguide. At the same time, there is a layer of back floor 10 on the other side of the dielectric substrate 2 corresponding to it, which is a metal Plating, the above constitute the feeder structure of the present invention. In the three operating frequency bands, the characteristic impedance of the feeder is approximately equal to 50 ohms, so that the connection of the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com